Why Top Construction Companies are Switching to Real-Time Fleet Tracking

5 Advanced Tracking Solutions to Boost Your Fleet's Performance Instantly

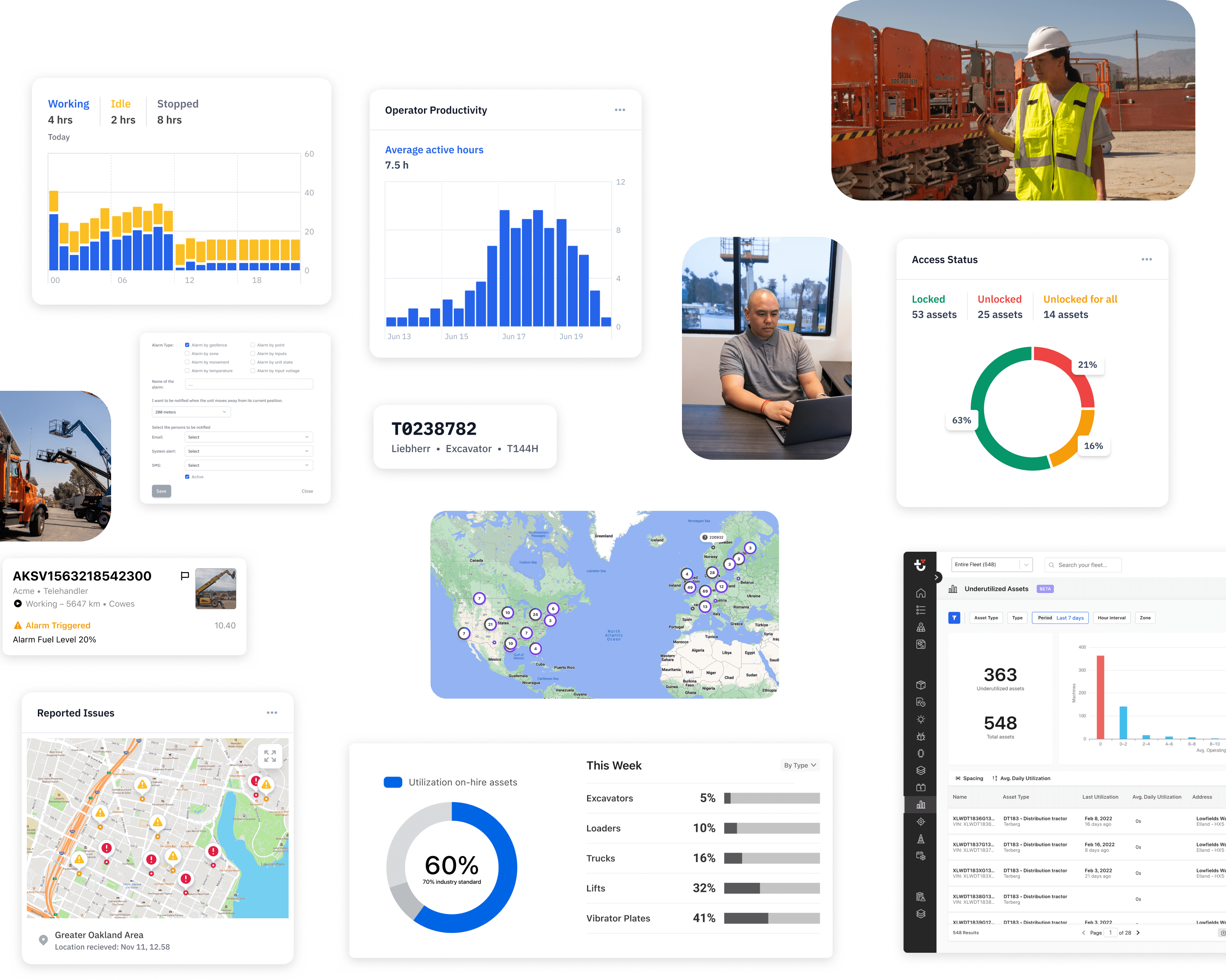

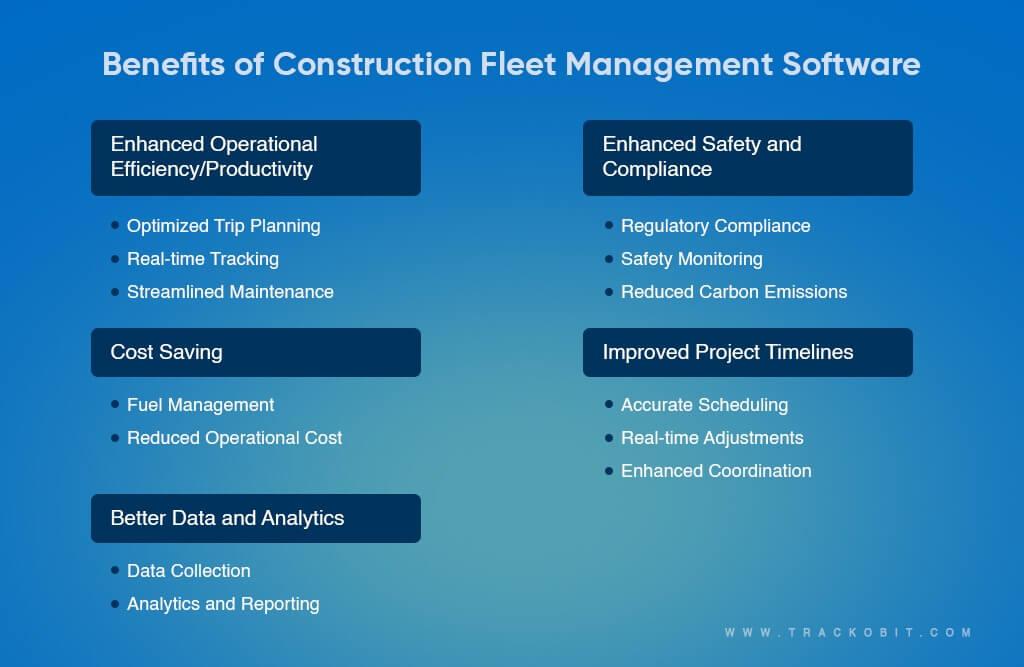

Enhance your fleet's performance instantly with these five advanced tracking solutions. Real-time GPS tracking provides immediate vehicle location data for optimized routing. AI-powered route optimization - learn more uses machine learning to improve efficiency and reduce fuel consumption. Predictive maintenance technology anticipates breakdowns, minimizing downtime and extending vehicle lifespan. Driver behavior monitoring tools offer real-time feedback on risky behaviors, improving safety and fuel efficiency. Integrated fleet management platforms consolidate these features into a user-friendly interface, streamlining operations and decision-making. By implementing these state-of-the-art technologies, you'll gain unmatched control over your fleet's performance and reveal new levels of productivity and profitability

Key Takeaways

- Implement real-time GPS tracking for instant vehicle location access and route optimization.

- Utilize AI-powered route optimization to reduce fuel consumption and improve delivery times.

construction fleet performance reporting

construction fleet performance reporting- Deploy predictive maintenance technology to prevent breakdowns and increase vehicle uptime.

- Adopt driver behavior monitoring tools for real-time feedback and targeted safety training.

- Integrate fleet management platforms to consolidate tracking tools and enhance data analysis.

construction fleet tracking solutions

construction fleet tracking solutionsReal-Time GPS Tracking Systems

Real-time GPS tracking systems form the backbone of modern fleet management solutions. These systems provide you with instant access to your vehicles' locations, enabling efficient route optimization and improved response times (how to track construction fleets). By leveraging satellite technology, you can monitor your fleet's movements with pinpoint accuracy, ensuring that drivers adhere to predetermined routes and schedules

One key feature of real-time GPS tracking is geofencing alerts. You can establish virtual boundaries around specific areas, receiving notifications when vehicles enter or exit these zones. This capability enhances security and helps prevent unauthorized use of your assets.

Additionally, these systems collect and store historical data - how to track construction fleets, allowing you to analyze trends and patterns in your fleet's performance over time. You can identify inefficiencies, track maintenance needs, and make data-driven decisions to improve overall operations

Real-time GPS tracking also contributes to driver safety. You can monitor speeding, harsh braking, and other risky behaviors, enabling prompt intervention and targeted training. By implementing these systems, you'll not only optimize your fleet's efficiency but also create a safer working environment for your drivers and reduce potential liability risks.

AI-Powered Route Optimization

Building upon the foundation of real-time GPS tracking, AI-powered route enhancement takes fleet management to the next level. By leveraging advanced algorithms and machine learning, you'll enhance your fleet's efficiency and safety. Fluid routing algorithms continuously analyze data from various sources, including traffic pattern analysis, to provide ideal routes in real-time.

This AI-driven approach offers several key benefits: - how to track construction fleets

- Reduced fuel consumption and emissions

- Improved on-time deliveries and customer satisfaction

- Enhanced driver safety through avoidance of high-risk areas

You'll find that AI-powered route enhancement adapts to changing conditions, such as accidents, road closures, or unexpected traffic congestion. This flexibility allows your fleet to maintain productivity while prioritizing driver safety. The system's ability to process vast amounts of data quickly enables it to make informed decisions that human dispatchers might overlook.

Predictive Maintenance Technology

Leveraging predictive maintenance technology enables fleet managers to anticipate and prevent (how to track construction fleets) vehicle breakdowns before they occur. This advanced approach employs predictive analytics to analyze data from various vehicle sensors, historical maintenance records, and operational patterns. By identifying potential issues early, you can greatly reduce unexpected downtime and costly repairs

real-time tracking for construction fleets

real-time tracking for construction fleetsPredictive maintenance systems continuously monitor critical components, such as engines, transmissions, and brakes. They use machine learning algorithms to detect anomalies and predict when parts are likely to fail. This allows you to schedule maintenance proactively, enhancing your fleet's overall performance and safety.

Implementing predictive maintenance technology offers several benefits: - how to track construction fleets

how to track construction fleets

how to track construction fleets- Reduced maintenance costs through timely interventions

- Increased vehicle uptime and productivity

- Enhanced safety by addressing potential issues before they become critical

- Improved maintenance scheduling efficiency

- Extended vehicle lifespan through effective care

To maximize the effectiveness of predictive maintenance, integrate it with your existing fleet management systems. This guarantees a thorough approach to vehicle health monitoring and maintenance planning. By adopting this technology, you'll not only improve your fleet's reliability but also enhance driver safety and operational efficiency.

Driver Behavior Monitoring Tools

Driver behavior monitoring tools offer fleet managers unparalleled comprehension into operator performance and safety. how to track construction fleets. These systems employ advanced telematics and AI-driven analytics to track and evaluate various aspects of driver behavior in real-time. By implementing these tools, you'll gain revelations that can considerably improve your fleet's efficiency and safety record

Key benefits of driver behavior monitoring tools include:

- Real-time feedback on risky behaviors such as harsh braking, rapid acceleration, and excessive idling

- Data-driven revelations for developing targeted safety training programs

- Improved fuel efficiency through identification of fuel-wasting habits

These tools enable you to implement effective driver engagement strategies by providing objective performance metrics. You'll be able to recognize and reward safe driving practices while addressing areas that need improvement. By integrating this data into your safety training programs, you can create personalized coaching sessions that address specific driver behaviors.

fleet vehicle tracking installations

fleet vehicle tracking installationsFurthermore, driver behavior monitoring tools can help reduce insurance premiums by demonstrating your commitment to safety - how to track construction fleets. They also provide significant evidence in case of accidents or disputes. By leveraging these advanced tracking solutions, you'll create a culture of safety and accountability within your fleet, ultimately leading to improved performance and reduced operational costs

Integrated Fleet Management Platforms

Through integrated fleet management platforms, you'll gain a thorough solution for overseeing all aspects of your fleet operations. These extensive systems consolidate various tracking tools into a single, user-friendly interface, streamlining your management processes and enhancing overall efficiency.

Cloud-based solutions offer real-time data access and storage, ensuring you're always up-to-date with your fleet's status. You'll benefit from seamless integration of vehicle tracking, driver behavior monitoring, and maintenance scheduling. This centralized approach allows for quick identification of potential issues and prompt implementation of corrective measures.

Mobile applications extend the platform's functionality, enabling you to manage your fleet on-the-go. You'll receive instant notifications about critical events, such as speeding incidents or maintenance alerts, allowing for immediate action to maintain safety standards.

track construction vehicles with advanced systems

track construction vehicles with advanced systemsThese platforms often incorporate advanced analytics tools (construction equipment fleet monitoring), providing beneficial understandings into your fleet's performance. You'll be able to generate detailed reports on fuel consumption, route optimization, and driver productivity, facilitating data-driven decision-making

Frequently Asked Questions

How Do Privacy Laws Affect the Implementation of Advanced Fleet Tracking Solutions?

construction vehicle tracking system

construction vehicle tracking systemYou'll face compliance challenges with privacy laws when implementing fleet tracking (how to track construction fleets). You must address data protection, consent requirements, and user transparency. Consider ethical implications and technological limitations while ensuring you meet legal standards for safety and privacy

What Is the Typical Return on Investment for Implementing These Tracking Solutions?

Hit the ground running with fleet tracking. You'll typically see ROI within 3-6 months through cost savings and improved performance metrics. Analyze fuel efficiency, route optimization, and maintenance schedules to maximize returns. Safety enhancements further justify the investment.

Can These Tracking Systems Integrate With Existing Fleet Management Software?

You'll find most tracking systems can integrate with existing fleet management software. However, you may face integration challenges due to software compatibility issues. how to track construction fleets. Evaluate your current system's specifications and choose a solution that guarantees seamless data exchange and operational safety

How Long Does It Take to Fully Implement and Train Staff on New Tracking Solutions?

You'll typically see a 4-8 week implementation timeline for new tracking solutions. Staff training can take 1-2 weeks. The process varies based on system complexity and your team's size. Prioritize thorough training for best safety outcomes.

Are There Industry-Specific Tracking Solutions for Specialized Fleets (E.G., Refrigerated Trucks, Hazardous Materials)?

Yes, you'll find specialized solutions for refrigerated tracking and hazardous tracking - how to track construction fleets. These systems offer customized performance metrics for your specific fleet needs, enhancing safety and efficiency. Implement industry-specific tracking to optimize your specialized operations effectively

Conclusion

You've investigated five state-of-the-art tracking solutions that can dramatically improve your fleet's performance. By implementing these technologies, you'll gain real-time knowledge. track construction vehicles with advanced systems, optimize routes, predict maintenance needs, monitor driver behavior, and streamline operations. Studies show that fleets using advanced tracking systems can reduce fuel consumption by up to 25%. Don't hesitate to invest in these tools; they'll provide immediate returns through increased efficiency, reduced costs, and enhanced safety. Stay ahead of the competition by embracing these innovative solutions for your fleet management strategy