The core of a compact heat exchanger is a set of heat-transfer plates.

The plates form channels where the hot and cold media flow on alternate sides. Most models have flat plates but in a spiral heat exchanger they have been curled up to form a spiral. The highly turbulent flow gives compact heat exchangers high heat transfer efficiency. The overall heat transfer coefficient is up to five times greater for a compact heat exchanger than a shell-and-tube. This means a compact heat exchanger is much smaller than a comparable shell-and-tube.

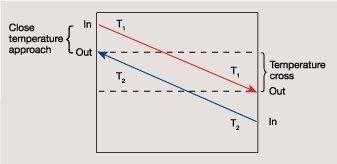

Crossing temperatures and close temperature approach

The overall flow of the two media is counter-current in a compact heat exchanger, i.e. the hot medium exits where the cold medium enters. This means the cold medium can be heated to a temperature very close to that of the entering hot medium. The temperature difference, ΔT, can be as low as 2°C (3.6°F).

The counter-current flow allows a compact Plate heat exchanger to operate with crossing temperatures, meaning the cold medium can have a higher exit temperature than the exiting hot medium.

The close temperature approach means the heat exchanger requires less of the utility medium or you can use one with a temperature closer to that of the process medium. Both cases result in lower operating costs.

The combination of a close temperature approach and crossing temperatures makes it possible to recover maximum amounts of heat from the process and put it to use in other parts of the plant.