In the world of electronics manufacturing, Printed Circuit Board (PCB) assembly is a crucial process that involves placing various electronic components onto the board to create functional devices. However, despite stringent quality control measures, there are instances when errors or defects may occur during assembly, leading to the need for PCB assembly rework. Rework is a critical aspect of ensuring product reliability, and mastering the best practices and techniques is essential for any electronics manufacturing company.

Understanding PCB Assembly Rework:

PCB assembly rework refers to the process of correcting errors or defects in assembled circuit boards. These defects can range from soldering issues to compo

ent misplacement, shorts, opens, and even design flaws. Reworking a PCB involves disassembling and modifying the board to correct the identified problems while maintaining the integrity of the overall circuit.

Importance of PCB Assembly Rework:

Ensuring the highest quality and reliability of electronic products is paramount in today's competitive market. PCB assembly rework plays a pivotal role in achieving these goals for several reasons:

-

Cost-Effectiveness: Reworking a defective PCB is more cost-effective than scrapping the entire board and starting the assembly process from scratch.

-

Time Efficiency: Reworking a PCB allows for faster corrections, reducing the time required to get the product to market.

-

Reduced Waste: By salvaging and repairing defective boards, the environmental impact of electronics manufacturing is minimized.

-

Enhanced Reputation: Delivering products with top-notch quality builds trust and enhances the reputation of the manufacturer.

Best Practices for PCB Assembly Rework:

-

Thorough Inspection: Before beginning any rework, a comprehensive inspection of the PCB should be conducted to identify all defects and errors accurately.

-

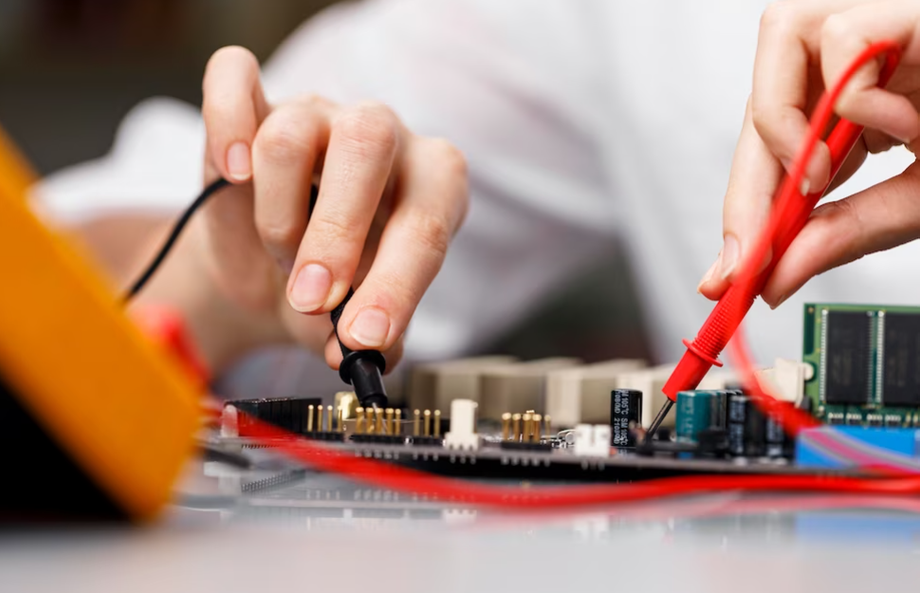

Appropriate Tools and Equipment: Using the right tools and equipment for specific rework tasks is vital to ensure precision and avoid further damage.

-

Component Removal Techniques: When removing components, techniques like hot air rework stations, soldering irons, or desoldering wands should be employed to minimize the risk of damage to the board or nearby components.

-

Component Replacement: For replacing defective components, it is crucial to ensure that the new component is of the correct type and properly aligned with the board.

-

Soldering Techniques: Skillful soldering is critical during rework. The use of lead-free and high-quality solder is recommended to achieve strong and reliable connections.

-

ESD Precautions: Electrostatic discharge (ESD) can irreparably damage electronic components. Following ESD precautions during rework is necessary to protect sensitive parts.

-

Workstation Organization: A clean and organized rework workstation ensures efficiency and minimizes the risk of errors during the rework process.

Techniques for Successful PCB Assembly Rework:

-

Component Removal:

- Use a hot air rework station or a soldering iron with the appropriate tip size to heat the solder joints and remove the component gently.

- Avoid excessive heat, as it may damage the PCB pads or adjacent components.

-

Pad Repair:

- If a pad is damaged during component removal, it can be repaired using an epoxy-based solder mask or conductive ink.

- Care should be taken to avoid short circuits or lifted pads during the repair process.

-

Component Replacement:

- Ensure that the replacement component is of the correct type, package, and specifications to match the original component.

- Align the component accurately and tack solder one pin before soldering the remaining pins.

-

Soldering Techniques:

- Use the right amount of solder to form a proper fillet and achieve a reliable electrical connection.

- Employ flux to improve solder flow and remove any existing oxidation.

-

Cleaning and Inspection:

- Thoroughly clean the reworked area to remove any flux residue or debris.

- Inspect the reworked area under a magnifier or microscope to verify the quality of the work.

Conclusion:

Mastering PCB assembly rework is an essential skill for electronics manufacturers seeking to maintain product quality and reliability. By adhering to best practices and employing the right techniques, companies can efficiently correct defects, reduce costs, and ensure customer satisfaction. The dedication to mastering rework practices demonstrates a commitment to delivering top-notch electronic products in an increasingly competitive market. With the continuous advancement in electronics technology, mastering PCB assembly rework is an ongoing journey for any electronics manufacturing professional.