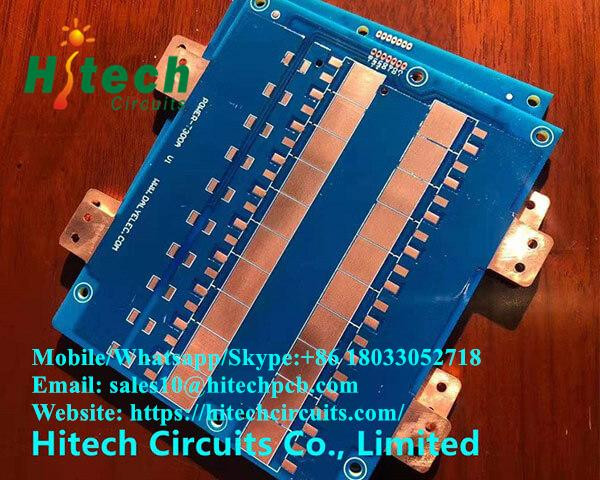

Hitech is a professional Heavy Copper PCB, Thick Copper PCB Board Manufacturer, PCB Power Supply Supplier from China, We have been engaged in Heavy Copper PCB Plating since 2000 and have earned a good reputation in this industry. If you have custom Heavy Copper PCB needs, please feel free to contact us sales@hitechcircuits.com .

What is a thick copper PCB board? Thick copper PCB boards (also known as thick copper boards, power boards, etc.) are usually laminated with a layer of copper foil on a glass epoxy substrate. The thickness of the copper foil is usually 18μm, 35μm, 55μm, 70μm, and the most commonly used copper foil thickness is 35μm. The thickness of the copper foil used in China is generally 35-50μm, and there are also thinner ones such as 10μm and 18μm; there are also thicker ones such as 70μm. The thickness of the composite copper foil on a substrate with a thickness of 1-3mm is about 35μm; the thickness of the composite copper foil on a substrate with a thickness of less than 1mm is about 18μm, and the thickness of the composite copper foil on a substrate with a thickness greater than 5mm is about 55μm. If the thickness of the copper foil on the PCB is 35μm and the printed line width is 1mm, the resistance value is about 5mΩ and the inductance is about 4nH for every 10mm length. When the di/dt of the digital integrated circuit chip on the PCB is 6mA/ns and the working current is 30mA, the noise voltage generated by each part of the circuit is estimated to be 0.15mV and 24mV respectively based on the resistance and inductance contained in each 10mm printed line.

Advantages of thick copper PCB

Thick copper boards have the characteristics of carrying large currents, reducing thermal strains, and good heat dissipation.

1. Thick copper circuit boards can carry large currents

When the line width is constant, increasing the copper thickness is equivalent to increasing the cross-sectional area of the circuit, which can carry a larger current, so it has the characteristic of carrying large currents.

2. Thick copper circuit boards reduce thermal strain

The conductivity (also known as resistivity) of copper foil is small, and the temperature rise is small when a large current passes through it, so it can reduce heat generation and thus reduce thermal strain.

Metal "conductors" are divided into: "silver → copper → gold → aluminum → tungsten → nickel → iron" according to conductivity.

3. Thick copper circuit boards have good heat dissipation

The thermal conductivity of copper foil is high (thermal conductivity 401W/mK), which plays an important role in improving heat dissipation performance, so it has good heat dissipation;

The thermal conductivity refers to the heat that passes through 1 square meter of area within 1 hour under stable heat transfer conditions, for a 1 meter thick material with a temperature difference of 1°C on both sides, measured in W/m·K.

Mobile/Whatsapp/Skype:+86 18033052718

Email: sales10@hitechpcb.com

Website: https://hitechcircuits.com/pcb-products/heavy-copper-pcb/