Introduction:

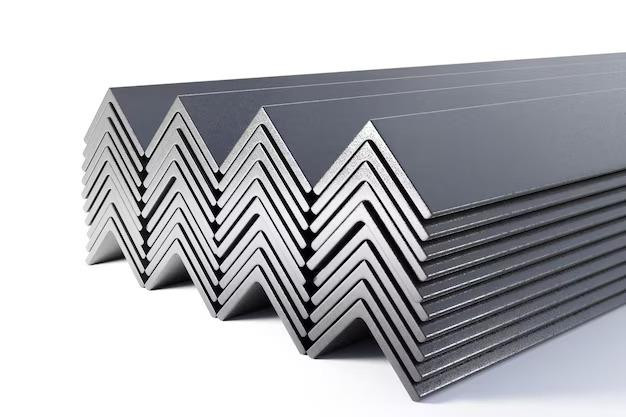

Mild Steel (MS) angles are a fundamental component in the construction and manufacturing industries, playing a crucial role in various applications. These L-shaped structural elements are known for their versatility, strength, and cost-effectiveness. In this blog article, we will delve into the characteristics, uses, and benefits of MS angles, shedding light on why they are indispensable in a wide range of projects.

Understanding MS Angles:

MS angles, also known as mild steel angles or L-shaped sections, are made from low carbon steel and exhibit excellent strength and ductility. The manufacturing process involves hot rolling, which imparts these angles with a robust structure. The two legs of the angle are of equal length, forming a 90-degree angle. MS angles come in various sizes, thicknesses, and lengths, making them suitable for diverse applications.

Key Characteristics of MS Angles:

- Strength and Durability: MS angles are renowned for their high strength, making them ideal for supporting heavy loads in construction projects.

- Ductility: Mild steel possesses excellent ductility, allowing for easy fabrication and shaping of MS angles to suit specific requirements.

- Weldability: MS angles are easily weldable, facilitating the joining of different components in construction and manufacturing processes.

- Cost-Effective: Compared to other materials, mild steel is cost-effective, making MS angles a budget-friendly choice for various applications.

Applications of MS Angles:

1.Construction Industry:

- Structural Frameworks: MS angles are widely used in the construction of buildings, bridges, and other structures to provide strength and stability.

- Support Structures: They are commonly employed as support brackets, trusses, and frames, distributing loads effectively.

2.Manufacturing Sector:

- Fabrication: MS angles are extensively used in the fabrication of machinery, equipment, and components due to their versatility and ease of fabrication.

- Racking Systems: They play a crucial role in the construction of storage racks and shelving systems, providing a sturdy framework.

3.Infrastructure Projects:

- Railings and Fencing: MS angles are utilized for creating durable railings and fencing in infrastructure projects, ensuring safety and security.

- Poles and Posts: They are employed in the construction of utility poles and signposts, offering structural support.

4.Automotive Industry:

- Vehicle Frames: MS angles find applications in the manufacturing of vehicle frames and chassis components, providing strength and stability.

Benefits of Choosing MS Angles:

- Versatility: MS angles are adaptable to various applications, making them suitable for a wide range of industries.

- Cost-Effective: Mild steel is an economical choice, making MS angles a cost-effective solution for construction and manufacturing projects.

- Ease of Fabrication: The ductility and weldability of mild steel make it easy to fabricate and customize MS angles according to specific project requirements.

Conclusion:

In conclusion, MS angles are indispensable components in the construction and manufacturing sectors, offering a winning combination of strength, versatility, and cost-effectiveness. As technology advances, the significance of MS angles is likely to persist, contributing to the development of robust and enduring structures across various industries.