1 Wafer test environment

Wafer test system belongs to the Fab completed after the process, but also in the clean room environment, but also requires us to have a very strict electrostatic can be controlled. Usually this case of wafer testing clean room environment level for Class 1000, there is also a machine requires students to use in Class 10000. but they are for some Sensor chip technology may develop requirements to Class 100. operation staff information must be through the whole body wearing anti-static dust-free clothing anti-static gloves, production and storage of different areas between the installation and ionizing fans to remove static electricity. Installation of an ionizing fan to remove static electricity.

The clean room ambient temperature is 22 degrees ± 2 degrees. Temperature: 55% ± 5%, dust-free environment to control particulate matter and bacterial growth.

2 Wafer Testing Process Flow

The basic flow of wafer testing can be divided into material receiving, receiving inspection, testing, inking, final inspection and shipping inspection. As shown in the figure below. Some special chips can be repaired with a laser after the first test (Focused Ion Beam Technology FIB) and then a second test. The process flow is shown below.

1) Material Receiving

After the wafer test is completed, it is necessary to input the wafer WAT test data, as well as the wafer lot number, product model, quantity and other verification and inspection records into the material system. At the same time, the entire crystal ship case is put into the nitrogen tank for storage.

2) Wafer Appearance Inspection

Before the wafer test, it is necessary to visually inspect the wafer appearance under a metallurgical microscope to check whether the wafer has missing corners, scratches, contamination, discoloration of pads, pinholes, slots, and whether the wafer number is consistent. Generally large factories use automatic scanners to pick up all wafer lines. The scanner uses an image recognition algorithm to compare and judge the defective templates, mark the defective locations of the wafers, and then confirm them manually. Judgment is made according to wafer inspection standards and operating instructions. If any abnormality is found, it is marked according to the operation instructions. Pass the inspection and put the qualified wafers into the system for the next operation.

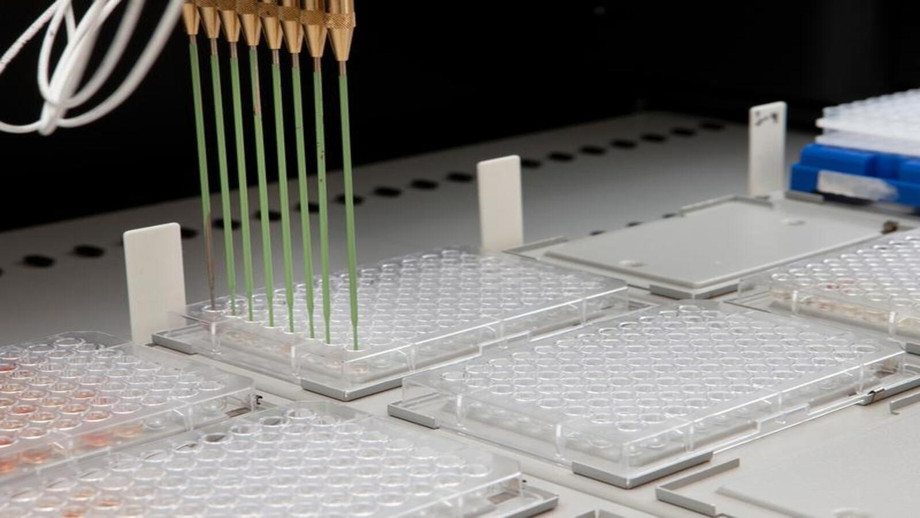

3) Wafer Probe Test

Fully automatic probe test bench automatically up and down the piece, the operator only we have to put the wafer piece to the pre-alignment table to do a good job of pre-alignment, and then the piece will be sent to the bearing table waiting for a host component data processing. At the same time through which it will also be the host system test work is completed piece sent back to the box to go. Test management process is analyzed as follows

(4) playing the ink point

After the completion of wafer testing, the quality or classification of each grain is usually saved as a wafer map for back-channel packaging chip components. There is also back when the core does not apply the mapping, but directly to the bad ink dots on the not Zhu film, not Zhu film on the not Zhu need to go through the baking, not Zhu glue drying fixed on the surface of the not Zhu grain. In the subsequent installation process, the chips are also categorized according to image recognition.

1) Inking Dot

Test inked wafers for final inspection. Information such as wafer lot number, lot number, and customer lot number are checked for confirmation. Then, an appearance inspection is performed to check whether there are any defects in the wafers during the previous wafer testing process. The criteria are basically the same as the previous wafer appearance inspection, but more attention is paid to the effect of wafer probes on wafer pads. Pinholes, etc.

3 wafer test defective

The purpose of product testing is to find as many product design errors, and use the test results to monitor the stability of the process of previous production, and timely feedback to the design and process. But found that the product itself is the premise of the problem is to test the stability and reliability of the test itself. So the tester itself needs to ensure reliability, repeatability and reproducibility. The evaluation of the test machine can be realized through the repeatability and interchangeability test (GRR).

Repeatability means that the same operator repeats the test on the same batch of test samples with consistent results. Interchangeability is the consistency of test results when different operators test a batch of products. There are two main problems with product testing.

1) Good products for testing and analyzing the results for FAIL, known as misuse (Overkill)

2) Passing of bad product testing is known as Overkill.

The probability of overkill for mass produced products is very small and the main problem is mis-slaughter due to machine or operational reasons. The product itself, however, is wasted due to mis-slaughter, reduced test yields, or reduced test efficiency due to repetitive testing. Meanwhile, repeated testing has caused many pinholes on the chip pads. If the proportion of needle marks is too large, it will reduce the reliability of subsequent packaging and wiring. However, false slaughter is only a phenomenon in product testing, and further causes need to be specifically analyzed.

3.1 Methods to analyze the problem

Industrial products have a variety of quality characteristics, but due to a variety of input factors in the production process, such as materials, personnel, equipment, environment, methods, etc., the quality of the product will appear a variety of different quality characteristics.

In order to solve quality problems, the relationship between quality characteristics (results) and causes is clarified, and the factors caused by quality control are referred to as primary causes. Therefore, a graphical representation of the elements of a quality characteristic is called a characteristic factor diagram. It is also called a fishbone diagram because it is shaped like a fish that has no meat but only bones. The following diagram

(1) Human analysis:

Where the operating management personnel play a leading role in the production of defects in the process, generally we can control the system by the operating technicians to control the main problems caused by operational errors cause:

① poor quality consciousness;

② carelessness in operation;

③ Do not comply with the operating procedures;

Low operating skills, unskilled technology ;① Poor quality awareness.

(5) Boredom due to simple repetitive work.

How to improve productivity should first be explored from the existing employees, to utilize their characteristics as much as possible, to stimulate the employees' motivation and to improve their work motivation. Human resource course is a science that specializes in studying how to improve the efficiency of employees' work and motivate them to work within a unit of time. In conclusion, personnel management is one of the most complex and difficult forms of production management to understand and utilize.

? Control measures can be taken:

① Strengthen the quality consciousness education of "quality first, customer first, customer is the next process" and establish a sound quality responsibility system;

② Prepare a clear and detailed operating system process, strengthen the process of professional knowledge training, the issuance of operating certificates;

Strengthen the inspection work, and appropriately increase the frequency of inspection.

(4) through the adjustment of personnel between jobs and rich work experience to eliminate operator boredom;

QCC quality control circle activities promote self-improvement and self-improvement ability.

(2) Analysis of machines:

It refers to the equipment, tools and other auxiliary production equipment used in production. Good equipment can improve production efficiency and product quality. In production, the normal operation of equipment and the quality of tools is another factor that affects the production progress and product quality. An enterprise is developing, in addition to the quality of people is improving, the external image of the enterprise is improving; it can be analyzed from the following aspects.

① Is the selection right?

② maintenance problems?

③ to the machine's supporting enterprises correspond?

4 is the person who makes the machine, right? Is the machine operated correctly? Is the machine suitable?

The main control measures are:

(1) Strengthen the maintenance of equipment, regular testing of key precision and performance items of machinery and equipment, the establishment of a daily inspection system for key parts of the equipment, and key control of the equipment in the process quality control points;

(ii) Check the adjustment of the positioning or dosing device through the first piece inspection.

(iii) Automatic display and automatic recording devices for positioning data should be configured as far as possible to reduce the dependence on the reliability of workers' adjustment.

(3) Analysis of methods:

It refers to the regulations and management system that we need to follow in the process of production development. It includes: process instructions, standard workflow guidelines, production drawings, production schedules, product work evaluation standards, inspection standards, and various information operating procedures. Their role here can be to standardize the production and operation process of enterprise products and timely and accurately reflect the requirements of the company's product and service quality. Strictly in accordance with the regulations of the operation, is to ensure the quality of their products and production schedule is an important condition.

is a correct method

② see the understanding

③Write understand?

④ Is the method suitable?

⑤ Is there a clear regulation?

6. Is the method for the corresponding person? Is the method effective in this environment?

Process error prevention and control measures.

1 Ensure the accuracy of the positioning device, strict inspection of the first piece, and ensure the accuracy of the positioning center to prevent the processing characteristic value data distribution center from deviating from the specification center; and

② Strengthen the information technology enterprise business for training, so that the operation and management personnel are familiar with the installation of positioning devices and adjustment of teaching methods, as far as possible to configure the device to display positioning data;

3 to strengthen the fixed cutting tools or cutting tools sharpening and management, the implementation of mandatory replacement system;

④ Actively carry out control chart management so that timely measures can be taken to make adjustments;

Serious process discipline and implementation of operating procedures for inspection and supervision.

(6) Strengthen the management of tools, tools and measuring instruments, and do a good job of cycle inspection of tools and molds and cycle calibration of measuring instruments.

(4) Analysis of the environment

Generally refers to the temperature, humidity, noise interference, vibration, lighting, indoor purification and the severity of on-site pollution at the site of production activities. In addition to ensuring the special educational requirements of the enterprise products on environmental development conditions, but also to do a good job in the construction site of the finishing, reorganization and cleaning work, and vigorously engage in civilized social production, for the lasting production of high-quality service product innovation to create a condition.

1 Whether the environment changes on the time line

② 6 Has light, temperature, humidity, altitude and pollution been considered?

③ Is the environment safe

4 Is the environment man-made? Can size coexist?

(5) Analysis of materials

It refers to materials, semi-finished products, auxiliary materials, and raw materials. In the work of production management, we must pay close attention to the progress of semi-finished products sent by the previous process, accessories in the warehouse, and semi-finished or finished products produced by this process. A good manager is one who can look at the whole picture; one who can think of everyone.

①Is it the real thing?

② Is it the right model?

③Is there a shelf life?

③Is there a shelf life?

⑤Is the material used in accordance with the specifications?

(6) Is the material adapted to the social environment, is the material compatible with the machine, and does the material and other materials learn from each other?

(7) Analysis of measurement

It mainly involves measurement tools, measurement methods, and trained and authorized surveyors. The use of prescribed, regular testing of measuring tools, uniform standards of measurement methods, to ensure that the same measurement point, the same measuring tools, different measurement personnel to minimize the error of measurement data. Measurement data shall be recorded in the production process.

①Is the responsible person designated

② the use of prescribed measuring tools

③ At the specified measurement point

①Apply the correct measurement method

⑤Measurement is performed according to a certain frequency

⑥ and recorded

The main control measures include:

(i) Determine the measurement task and required accuracy, select the use, with the required accuracy and precision capability of the test equipment.

② Periodically confirm, calibrate and adjust all measurement and test equipment.

③ Provide for the conduct of the necessary calibration protocols. Its content mainly includes the type of enterprise equipment data, number, location, calibration cycle, calibration method, acceptance management method, acceptance criteria, and measures to be taken when developmental problems occur in society.

④ Keep calibration records.

If it is found that the measurement and test equipment is not in a calibrated state, the validity of the previous measurement and test results will be immediately evaluated and recorded in the relevant documents.

3.2 Adverse Phenomena

In the process of wafer testing, it will bring some defects to the wafer itself. So wafer defects can be divided into

1) The chip itself is not good, including chip design and chip process is bad.

2) Test introduced defects, including the wrong test and damage to the wafer.

Chip itself is bad, in the wafer testing process research can be obtained from the test test data information management analysis, to find their own design or process reasons, teaching design and process improvement. For the test process itself can be effective use of the above analysis and processing methods need to be analyzed man-machine-material method ring fishbone diagram. The following chart for the test of poor social issues in the comparative analysis

Figure 4 bad analysis fishbone diagram

Operator problems:

Wafer testing, the operator did not set the operating parameters as required, or unskilled operation, operational errors lead to incorrect probe insertion, resulting in testing errors.

Negligence must be avoided in the testing process or test fixture design measures. We also regularly train employees in their skills and prepare easy-to-understand training documents. Only those who pass the test can be hired. Understand the mentality of employees in time to avoid bad working attitude leading to operation not serious.

Figure 3 Test pad exposed copper

Probe machine table problem:

The needle pressure design of the probe table, needle pressure changes, the flatness of the chuck, and the maintenance of the probe table shaft all affect the pressure accuracy and positional accuracy of the test probes, wafer testing thus affecting the test accuracy. It is necessary to carry out regular maintenance of the machine, develop a good maintenance plan, statistical analysis of frequent failures, early warning maintenance.

Probe card problems:

Probe card is an important influence on the wafer test materials, test and analysis results can play an important role, the probe card in the test work process we use a different number of times more, the probe card probe will appear loss, showing the probe tip is too short leading to uneven, probe tip coarsening and other abnormalities. Especially in the number of tests in the use of the probe network life, and then the probability of using the situation of psychological test data errors greatly increased.wafer probe The establishment of the probe card maintenance maintenance program, the establishment of the probe card management accounting system to develop statistical methods to use the table, in the test before the test process and after the test on the probe card to learn the state of information to confirm, to ensure that the state of the probe card is correct. Do a good job of safety marking the abnormal probe card to avoid being misused.

Test Methods:

In the wafer test process, the design of the test program is consistent with the use of downward pressure on the test probes. Test whether the data read by the software is processed correctly. probe holder Whether the test standard is within the margin of the chip parameters will affect the judgment of the test results.

Environmental issues:

Changes in the temperature and humidity of the test environment and high and low temperature conditions can affect the test parameters of the test probe and test board. Vibration in the test environment may have a great impact on the whole test. Therefore, it is very important to study the test conditions. Control and monitor the ambient temperature and humidity of the test plant, and take timely measures if they are exceeded.

精選文章:

Non-standard mechanical design and selection: How many types of probes are there?