In the fast-paced world of automotive manufacturing, efficiency is paramount. As the industry evolves, manufacturers are continuously seeking innovative solutions to streamline operations and enhance productivity. Advanced embedded software design plays a crucial role in this transformation, offering new capabilities that improve not only the manufacturing process but also the overall quality of the final product. This blog explores how advanced embedded software design is revolutionizing automotive manufacturing and driving efficiency across the industry.

The Role of Embedded Software in Automotive Manufacturing

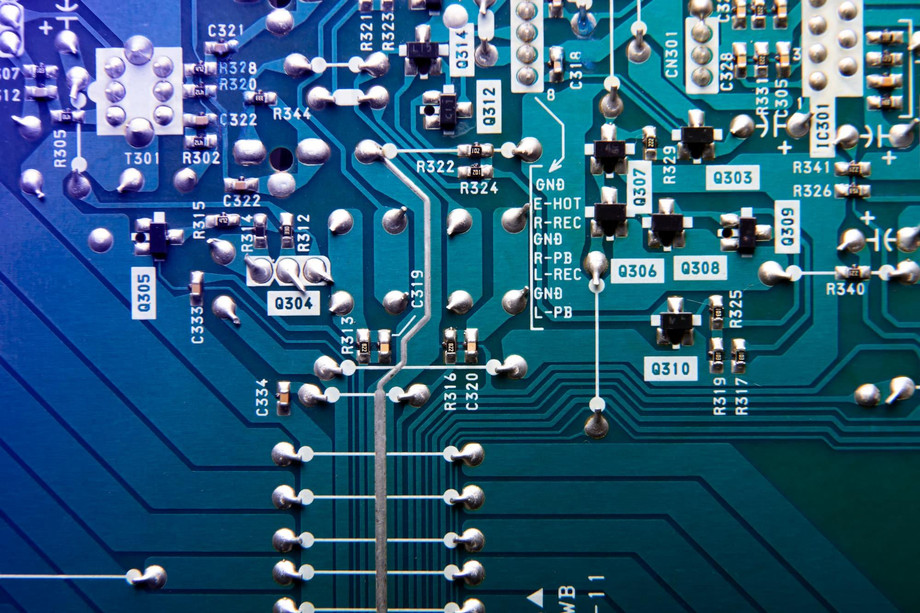

Embedded software is an integral part of modern automotive systems, controlling everything from engine management to infotainment systems. Its significance in manufacturing lies in its ability to optimize processes, improve real-time data collection, and facilitate communication between various components of the manufacturing system. By utilizing advanced embedded software, automotive manufacturers can ensure that their production lines operate smoothly and efficiently, reducing downtime and minimizing waste.

Streamlining Production Processes

One of the primary benefits of advanced embedded software design is its ability to streamline production processes. Traditional manufacturing techniques often rely on manual intervention, leading to increased labor costs and the potential for human error. However, with embedded software, processes can be automated, allowing machines to operate independently while gathering critical data for analysis.

For instance, advanced embedded systems can monitor machinery health and performance in real-time, providing manufacturers with actionable insights. This proactive approach to maintenance—often referred to as predictive maintenance—enables manufacturers to address potential issues before they lead to costly breakdowns. By reducing unplanned downtime, companies can maintain consistent production schedules, significantly improving efficiency.

Enhancing Quality Control

Quality control is a vital aspect of automotive manufacturing. With the integration of advanced embedded software, manufacturers can implement sophisticated quality assurance measures directly on the production line. Embedded systems equipped with advanced sensors can detect defects in real-time, ensuring that only high-quality components proceed through the manufacturing process.

This technology allows for immediate corrective actions, minimizing the risk of defective products reaching the market. As a result, manufacturers can improve their reputation for quality, leading to increased customer satisfaction and loyalty. Moreover, the data collected during the quality control process can be analyzed to identify trends and areas for improvement, further enhancing overall manufacturing efficiency.

Optimizing Supply Chain Management

Efficient supply chain management is essential for automotive manufacturers aiming to reduce costs and improve productivity. Advanced embedded software facilitates better inventory management, ensuring that the right components are available when needed. By integrating embedded systems into supply chain operations, manufacturers can track inventory levels in real time, automatically reordering supplies as needed.

This optimization extends to logistics as well. Embedded software can provide detailed insights into transportation routes, helping manufacturers identify the most efficient paths for delivery. By reducing transportation costs and improving delivery times, manufacturers can enhance their overall operational efficiency and competitiveness in the market.

Facilitating Advanced Robotics and Automation

The rise of automation in automotive manufacturing is largely driven by advanced embedded software design. Robotics systems, powered by sophisticated embedded software, can perform repetitive tasks with precision and speed, reducing labor costs and increasing output.

Moreover, these robotic systems can be integrated with machine learning algorithms, allowing them to adapt to new tasks and improve over time. This adaptability is particularly valuable in an industry where product designs are constantly evolving. By leveraging advanced robotics, manufacturers can respond more quickly to changing market demands, ultimately improving their production efficiency.

Enhancing Data Security

As automotive manufacturing becomes increasingly reliant on connected systems, data security has become a critical concern. Advanced embedded software design incorporates robust security features that protect sensitive data from potential breaches. By ensuring secure communication between devices and protecting against unauthorized access, manufacturers can safeguard their intellectual property and maintain compliance with industry regulations.

A secure manufacturing environment not only protects the company’s assets but also fosters trust with consumers, who are increasingly concerned about data privacy in connected vehicles. By prioritizing data security through embedded software, manufacturers can enhance their reputation and establish themselves as leaders in the industry.

Future Trends in Embedded Software for Automotive Manufacturing

The future of automotive manufacturing will undoubtedly see continued advancements in embedded software design. Emerging technologies such as artificial intelligence (AI), the Internet of Things (IoT), and 5G connectivity are set to further transform the industry. AI can enhance decision-making processes, allowing manufacturers to optimize operations based on real-time data analysis. IoT enables seamless communication between devices, creating a more interconnected manufacturing ecosystem.

As these technologies continue to evolve, the role of embedded software will become increasingly vital. Manufacturers that embrace these innovations will not only improve their operational efficiency but also position themselves at the forefront of the automotive industry.

Conclusion

Advanced embedded software design is reshaping the landscape of automotive manufacturing, driving efficiency and enhancing product quality. By streamlining production processes, optimizing supply chain management, and facilitating advanced robotics, manufacturers can significantly improve their operational capabilities. As the industry continues to evolve, embracing these technological advancements will be crucial for automotive manufacturers aiming to thrive in a competitive market. The integration of advanced embedded software is not just a trend; it is a strategic imperative for the future of automotive manufacturing.

To Know More About embedded software design