Zero air generators are essential tools for providing clean, hydrocarbon-free air, especially in environments where air purity is critical. Whether you work in a lab or an industrial setting, understanding how zero air generators work and why they are important can help you make the right choice for your needs. In this guide, we’ll break down everything you need to know about zero air generators in simple terms.

What is a Zero Air Generator?

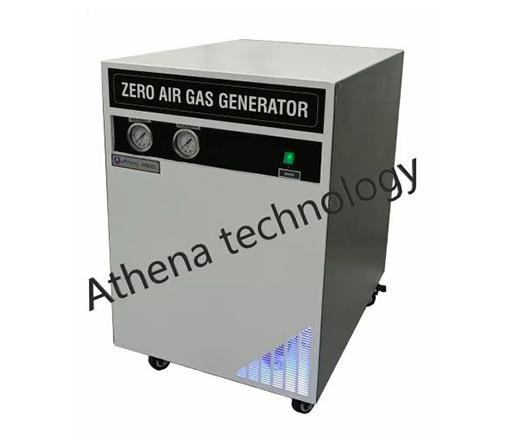

A zero air generator is a device that cleans and purifies air by eliminating hydrocarbons and other pollutants. This “zero air” is used in applications where even the slightest contamination can cause problems. For example, it’s essential for processes like gas chromatography, where the quality of air can affect the accuracy of results.

If you’re looking for the best manufacturer of scientific instruments, companies like Athena Technology are known for creating reliable and high-quality zero air generators that suit various industrial and laboratory needs.

Key Components of a Zero Air Generator

Zero air generators are made up of several key parts that work together to produce clean air:

- Air Compressor: This compresses the incoming air so that it can be filtered and purified.

- Catalytic Converter: This removes hydrocarbons from the air by breaking them down.

- Filters and Scrubbers: These remove moisture, carbon dioxide, and other impurities.

- Storage Tank: The purified air is stored here until it’s ready to be used.

Each of these components plays a crucial role in ensuring that the air produced is clean and pure.

How Zero Air Generators Work

The process of generating zero air is pretty straightforward. Here’s how it works:

- Air from the environment is drawn into the generator.

- The air passes through an air compressor, which pressurizes it for the next steps.

- The pressurized air goes through a catalytic converter that removes hydrocarbons by breaking them down into harmless components like carbon dioxide and water.

- After this, the air passes through filters and scrubbers that remove moisture and other particles, ensuring the air is completely clean.

- Finally, the purified air is stored in a tank and is ready to be used in whatever application is needed.

Advantages and Benefits of Zero Air Generators

There are several benefits of zero air generators, especially when it comes to industries that require a high level of air purity:

- Improved Air Quality: The air produced is free of impurities, making it perfect for sensitive applications like gas chromatography.

- Reduced Contamination Risk: Using zero air helps reduce the chance of contamination, ensuring that processes run smoothly and results are accurate.

- Cost-Effective: While the initial investment might seem high, zero air generators are very low-maintenance and energy-efficient, which saves money in the long run.

Applications of Zero Air Generators

Zero air generators are used in a wide range of industries:

- Gas Chromatography: These devices help provide clean air for testing and analysis in laboratories.

- Environmental Monitoring: Zero air is crucial in keeping air pollution monitoring equipment functioning properly.

- Industrial Processes: In some manufacturing settings, clean air is necessary to ensure product quality and equipment longevity.

- Research Facilities: Many labs rely on zero air to conduct experiments without interference from airborne impurities.

If you’re searching for the best manufacturer of laboratory equipment, it’s essential to choose one that understands these diverse applications and offers high-performance devices tailored to your specific needs.

Factors to Consider When Choosing a Zero Air Generator

Not all zero air generators are created equal, so it’s important to know what to look for:

- Purity Level: The level of air purity you need will depend on the application. Some processes require extremely pure air, while others may not.

- Flow Rate: Make sure the generator you choose can produce air at the flow rate you need for your specific application.

- Energy Efficiency: Some zero air generators are more energy-efficient than others, so choose one that fits your budget and operational needs.

- Maintenance Requirements: Look for a generator that is easy to maintain and has a long lifespan to avoid frequent repairs.

Common Challenges and Troubleshooting Tips

Like any piece of equipment, zero air generators can sometimes run into issues. Here are a few common problems and tips to solve them:

- Reduced Air Flow: This could be caused by a clogged filter. Check and replace filters regularly to avoid this problem.

- Poor Air Quality: If the air isn’t as pure as it should be, the catalytic converter may need cleaning or replacing.

- High Operating Costs: Regular maintenance can help keep costs down. Clean filters and replace parts as needed to ensure your generator runs efficiently.

Conclusion

Zero air generators play a vital role in ensuring clean, purified air in various industries. Whether you’re working in a lab or an industrial setting, understanding how these devices work and their benefits can help you choose the right generator for your needs. With the right zero air generator, you can improve air quality, reduce contamination risks, and save money over time.

By following this guide, you’ll have all the essential information to make an informed decision about zero air generators.