In today’s fast-evolving industries, maintaining sterility, flexibility, and efficiency is more important than ever. Single use tubing has become a game-changer, especially in sectors like pharmaceuticals, biotechnology, and food processing. With innovations from foxxlifesciences, these disposable systems are setting new standards for safe and reliable fluid transfer.

Email Us : sales@foxxlifesciences.com

What Is Single Use Tubing?

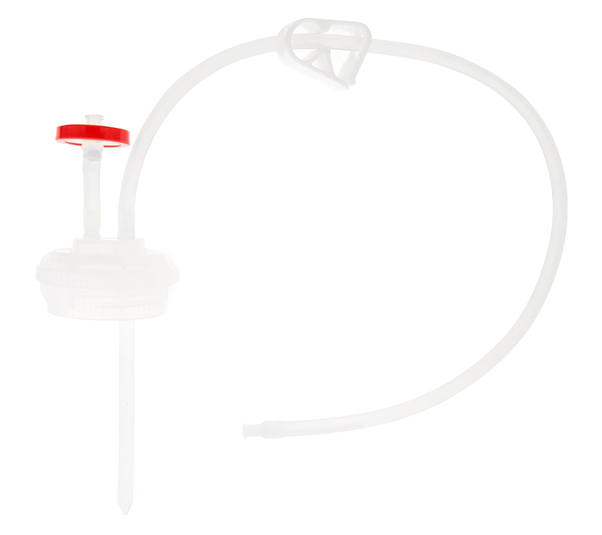

Single use tubing refers to disposable, pre-sterilized tubing systems used for transferring liquids in controlled environments. Unlike traditional stainless steel or reusable tubing, these systems are designed for one-time use, reducing cleaning and validation efforts.

Importance of Single Use Tubing in Modern Industries

The demand for sterile and contamination-free environments is driving industries toward single use technologies. Whether you’re manufacturing vaccines or handling sensitive biological materials, single use tubing ensures integrity, compliance, and speed in production processes.

How Single Use Tubing Differs from Traditional Tubing

Traditional tubing requires intensive cleaning and sterilization, which takes time and resources. Single use tubing eliminates these steps entirely. Each set is pre-assembled, sterile, and ready for immediate use—saving time while minimizing risk.

Key Benefits of Single Use Tubing

5.1 Enhanced Sterility

Every piece of tubing is gamma irradiated or autoclave sterilized, ensuring the system is free from contaminants.

5.2 Reduced Cross-Contamination

Since the tubing is used once and discarded, there’s no risk of cross-contamination, crucial for sensitive pharmaceutical and biotech processes.

5.3 Improved Efficiency

Set up, use, and disposal are quick and straightforward—cutting production downtime significantly.

5.4 Lower Maintenance Costs

No need for costly cleaning validation or sterilization equipment—reducing overhead expenses while improving throughput.

Applications of Single Use Tubing

6.1 Pharmaceutical Manufacturing

Used for transferring APIs, buffers, and media during drug production.

6.2 Biotechnology

Essential in cell culture, fermentation, and filtration applications.

6.3 Food and Beverage Processing

Ensures hygienic handling of liquids and flavoring agents.

6.4 Chemical Production

Used for controlled fluid transfer and sampling in chemical formulations.

Why the Industry Is Moving Toward Disposable Systems

Disposable systems offer unmatched safety and flexibility. They are ideal for multi-product facilities, where cleaning validation between batches can delay production. Single use tubing simplifies operations and reduces regulatory risk.

Materials Used in Single Use Tubing

8.1 Silicone

Flexible, biocompatible, and widely used in medical and bioprocessing applications.

8.2 Thermoplastic Elastomers (TPE)

Excellent for welding and sealing, making them ideal for modular systems.

8.3 PVC and Other Polymers

Used in cost-effective systems where chemical compatibility is essential.

How Single Use Tubing Simplifies Process Validation

Traditional tubing requires documentation for every cleaning cycle. With single use systems, validation becomes straightforward—just confirm sterility and integrity, saving valuable time in GMP environments.

Role of foxxlifesciences in Single Use Tubing Solutions

foxxlifesciences is a global leader in providing innovative, high-quality single use systems for biopharmaceutical and laboratory industries. Their tubing solutions are engineered for precision, durability, and reliability.

Features That Make foxxlifesciences Stand Out

-

Gamma-irradiated, pre-sterilized tubing

-

Superior chemical compatibility

-

Custom assembly options

-

Meets USP Class VI and FDA standards

-

Designed for seamless integration in bioprocessing systems

With foxxlifesciences, customers gain access to trusted single use technologies that streamline production while maintaining compliance with international quality standards.

How to Choose the Right Single Use Tubing

When selecting the right tubing, consider:

-

Fluid compatibility

-

Pressure and temperature requirements

-

Flexibility and durability

-

Regulatory compliance

Partnering with foxxlifesciences ensures expert guidance and tailored solutions for every application.

Environmental Impact and Sustainability Factors

While single use tubing generates more waste than reusable systems, modern recycling programs and bio-based materials are helping offset environmental impact. Companies like foxxlifesciences are continuously investing in eco-conscious innovations.

Future Trends in Single Use Tubing Technology

Expect more automation, smart sensors, and eco-friendly materials to emerge. The future is moving toward fully integrated single use systems that combine tubing, connectors, and sensors for real-time monitoring.

Conclusion

Single use tubing is more than a convenience—it’s a strategic advantage for modern industries focused on sterility, speed, and efficiency. With trusted partners like foxxlifesciences, businesses can confidently embrace disposable technologies that enhance performance and compliance.

Email Us : sales@foxxlifesciences.com

https://www.linkedin.com/company/foxxlifesciences

https://twitter.com/foxxlifescience

https://www.facebook.com/foxxlifesciences

https://www.youtube.com/user/foxxlifesciences

https://www.instagram.com/foxxlifesciencesglobal/

https://www.pinterest.com/foxxlifesciences/