Parylene is a chemical compound applied to substrates using chemical vapor deposition (CVD). As it is deposited on the surface molecule by molecule, it forms a defect-free coating with great conformation. Parylene is capable of resisting chemicals. It is capable to protect products against substances, acids, corrosion, and more. Unlike traditional conformal coating, the Parylene Coating Process provides an ultra-thin coating, ensuring superior coverage.

Parylene conformal coating safeguards the exposition of PCBs in fraught situations such as dust, temperature, and moisture.

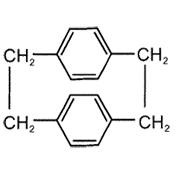

Parylene N

Coatings Chemicals Suppliers offer both Parylene C and Parylene N both are used for varied purposes, depending on your needs.

Parylene N is a widely used conformal coating. It is usually considered a basic type of coating as it is used for a variety of products. Also, it has a melting point of 420 °C (or 788 °F). Parylene N has unique vacuum stability and is ideal for applications of high frequency.

Its dielectric strength is much higher than that of parylene C. It also has unique molecular motion during deposition, which allows it to more closely conform to complex shapes. If you want to safeguard a difficult surface full of cracks, crevices, and tricky topography, then Parylene N is right for the job.

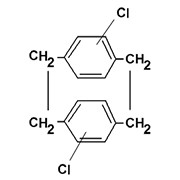

Parylene C

Parylene C is the most commonly used of all parylene types. It has a unique chemistry that makes it useful for varied purposes. It is highly resistant to corrosive gases, moisture, vapor, and various chemicals. A single chlorine atom used in place of Parylene N's aromatic hydrogen atom creates a completely different combination full of efficient properties. Parylene C is able to withstand vapor permeability, making it especially protective against gases.

Deciding Between Parylene C And Parylene N

There are many distinctions between Parylene C and Parylene N. It is important to keep in mind that both of them offer the same basic benefits, such as thermal stability, electrical insulation, longevity, and more.

When deciding between Parylene N and C, one needs to consider various things, such as the strengths and weaknesses of each type.

One should consider the operational context of the application. If your project involves exposure to high temperatures or requires superior dielectric strength, you should consider using Parylene N in such a case. On the other hand, if protecting the product against corrosive gases, Parylene C is the ideal choice.

Parylene N is able to easily adapt to complex shapes. This makes it ideal for safeguarding complex geometries prone to cracks and crevices. Ultimately, deciding between Parylene C and Parylene N requires a meticulous assessment of your application's requirements. One must also consider other factors like temperature resilience, dielectric strength, chemical resistance, substrate complexity, and budgetary constraints. It is advisable to seek advice from a Parylene Coating Manufacturer to choose the right coating to fulfill your requirements.

Source URL: https://medium.com/@dawntechnologies/how-to-decide-between-parylene-c-and-parylene-n-91832473cc7e