In the dynamic world of product creation, where innovation is crucial to success, manufacturers are constantly looking for cutting edge solutions that will streamline their processes and accelerate the release of products. One such innovation that has changed the game recently is laser cutting. This advanced production technique has shown to be the most effective means of accelerating the development of new products across several industries. We will discuss the causes of laser cutting’s rising popularity as well as how it has revolutionized the field of product development in this blog.

What Sets Laser-Cutting Apart from Conventional Methods?

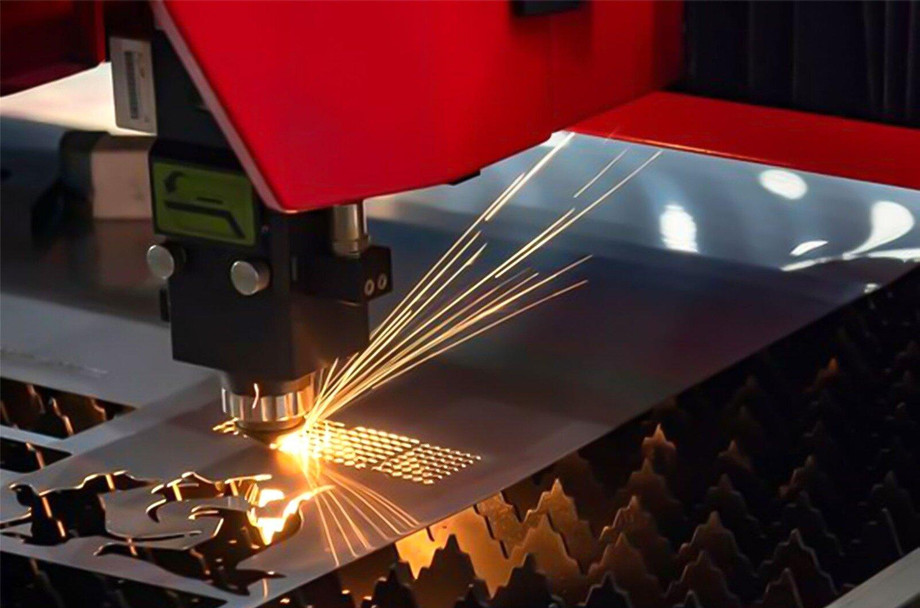

It’s important to understand how laser-cutting differs from conventional manufacturing techniques before exploring its benefits. A laser beam is used in the non-contact process of laser-cutting to accurately cut or imprint objects. When comparing this technology to traditional techniques like die-cutting or mechanical cutting, it delivers unmatched precision and versatility. Producers that wish to push the limits of product design will find laser-cutting to be an appealing option. It can create intricate shapes and complicated geometries with minimal material loss.

How Does Laser-Cutting Enhance Precision and Accuracy in Manufacturing?

In the process of developing new products, accuracy is crucial, and laser cutting excels at providing it in a way that traditional technologies find challenging. Manufacturers are able to make complicated parts with tight tolerances thanks to the focused laser beam’s ability to attain extremely tiny details. In fields where small, delicate parts are frequently used, like electronics, aircraft, and medical devices, this level of accuracy is very advantageous.

Additionally, laser cutting ensures constant quality throughout the production process by removing the possibility of tool wear associated with mechanical cutting methods. In order to satisfy the demanding standards of contemporary markets, where mediocre quality is not an option, this dependability is essential.