The automotive manufacturing industry is at a pivotal point, where advanced embedded hardware solutions are reshaping operations. As the sector embraces digital transformation, manufacturers are harnessing the power of embedded systems to enhance efficiency, increase safety, and streamline production processes. This blog explores the innovative applications of embedded hardware in automotive manufacturing, highlighting how these solutions are revolutionizing the industry.

The Role of Embedded Hardware in Automotive Manufacturing

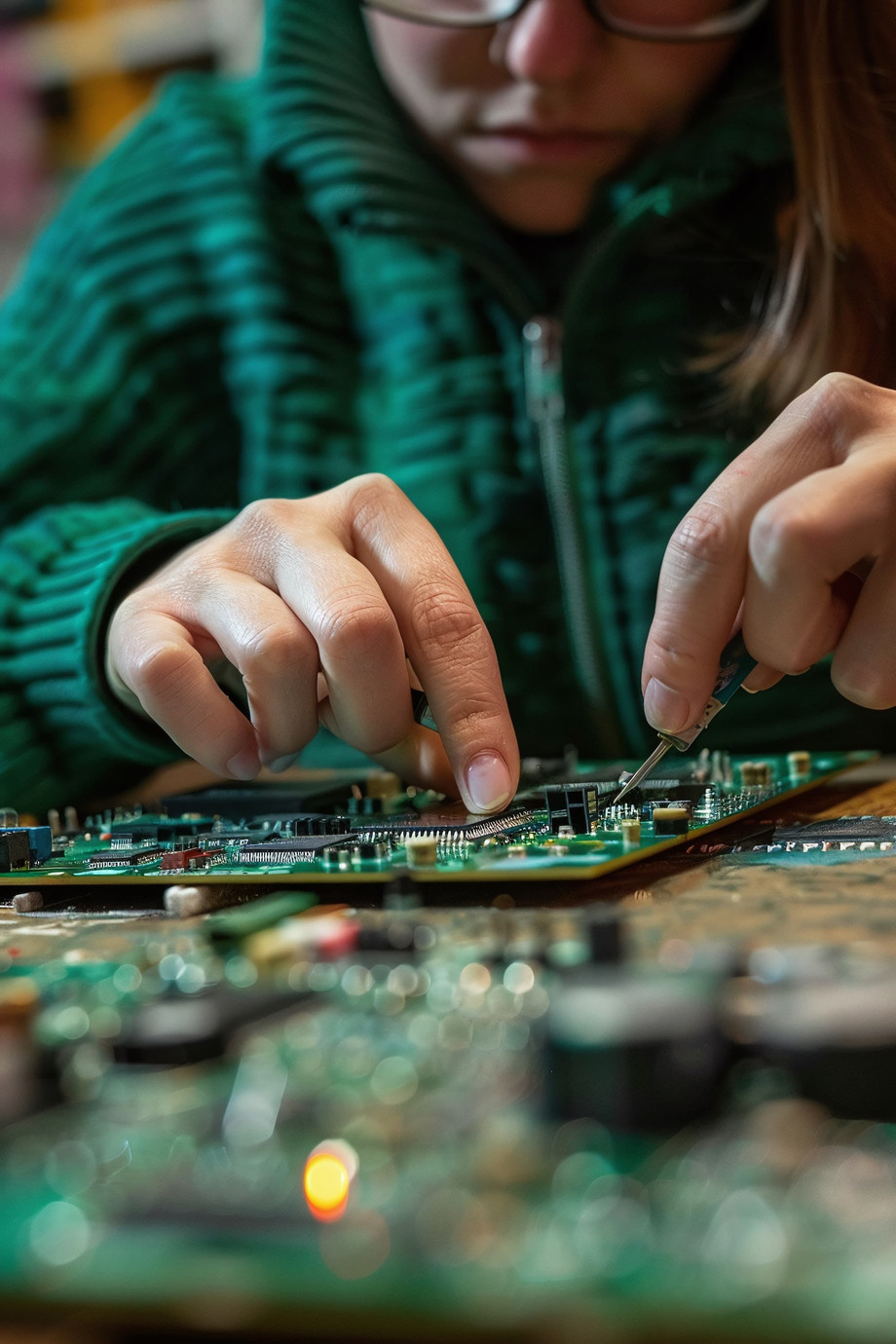

Embedded hardware serves as the backbone of modern automotive systems. From advanced driver-assistance systems (ADAS) to vehicle-to-everything (V2X) communication, embedded solutions are integral to the design and functionality of contemporary vehicles. These systems utilize microcontrollers, sensors, and communication modules to perform complex tasks, ensuring vehicles are smarter, safer, and more efficient.

Enhancing Manufacturing Efficiency

One of the most significant impacts of embedded hardware in automotive manufacturing is the enhancement of efficiency in production processes. Automated systems powered by embedded solutions can monitor and control various aspects of the manufacturing line. For example, embedded sensors can provide real-time data on machine performance, enabling predictive maintenance that reduces downtime and extends the lifespan of equipment.

Moreover, advanced robotics, equipped with embedded systems, can perform tasks with precision and speed that surpass human capabilities. These robots are programmed to adapt to various tasks on the assembly line, allowing for flexible manufacturing processes. By integrating embedded hardware into manufacturing operations, automotive companies can achieve higher output rates while maintaining quality standards.

Improving Safety and Quality Control

Safety is paramount in automotive manufacturing, and embedded hardware plays a crucial role in ensuring high safety standards. Quality control systems utilize embedded sensors to detect anomalies in production. For instance, vision systems equipped with embedded processing capabilities can inspect parts for defects in real-time, preventing faulty components from progressing through the production line.

Furthermore, the incorporation of ADAS in vehicles enhances safety for drivers and passengers alike. These systems rely on embedded hardware to process data from various sensors, such as cameras and radar, allowing vehicles to detect obstacles, lane markings, and traffic signals. As a result, the adoption of these technologies not only improves vehicle safety but also reduces the risk of accidents, benefiting both manufacturers and consumers.

Facilitating Smart Manufacturing

The shift toward Industry 4.0 is transforming traditional manufacturing into smart manufacturing. Embedded hardware is central to this transition, enabling seamless connectivity between machines, systems, and people. Internet of Things (IoT) technology, powered by embedded solutions, allows for real-time data exchange across the manufacturing ecosystem.

This connectivity empowers manufacturers to make informed decisions based on data analytics. For example, by analyzing production data, companies can identify bottlenecks in the manufacturing process and implement corrective actions swiftly. Additionally, IoT-enabled devices can monitor environmental conditions, ensuring optimal production settings that enhance product quality.

Supporting Electrification and Sustainability

As the automotive industry shifts toward electrification, embedded hardware solutions are essential in supporting this transition. Electric vehicles (EVs) require sophisticated embedded systems to manage battery performance, energy consumption, and charging infrastructure. Advanced embedded solutions optimize the efficiency of EV components, ensuring they operate effectively under varying conditions.

Moreover, sustainability is becoming a priority for automotive manufacturers. Embedded hardware can assist in monitoring energy usage and emissions during production, enabling companies to implement greener practices. By adopting sustainable manufacturing processes powered by advanced embedded systems, automotive manufacturers can reduce their environmental footprint while meeting regulatory requirements.

The Future of Automotive Manufacturing with Embedded Solutions

Looking ahead, the role of advanced embedded hardware in automotive manufacturing will continue to expand. As technology evolves, manufacturers will explore new applications for embedded systems, such as artificial intelligence (AI) and machine learning (ML). These technologies can enhance predictive analytics, improving decision-making processes across the manufacturing landscape.

Moreover, the growing demand for connected vehicles will drive the development of advanced embedded solutions that facilitate communication between vehicles and infrastructure. This evolution will pave the way for smarter cities, where traffic management systems can interact with vehicles to optimize flow and reduce congestion.

Conclusion

Advanced embedded hardware solutions are fundamentally transforming automotive manufacturing operations, driving efficiency, safety, and sustainability. As the industry adapts to digital advancements, the integration of embedded systems will remain a key factor in shaping the future of automotive manufacturing. By leveraging these technologies, manufacturers can enhance their operations, respond to market demands, and ensure they remain competitive in a rapidly evolving landscape. The journey towards smarter, more efficient automotive manufacturing is just beginning, and embedded hardware will be at the forefront of this transformation.

To Know More About embedded hardware solutions