Explored: Basics of PLC-

Basics of PLC you should know, before going for the advanced concepts.

Not knowing even the basics of PLC? Here is your chance to know the basics as we explore them for you. Once you get acquainted with the basics, eventually you can go for the advanced part.

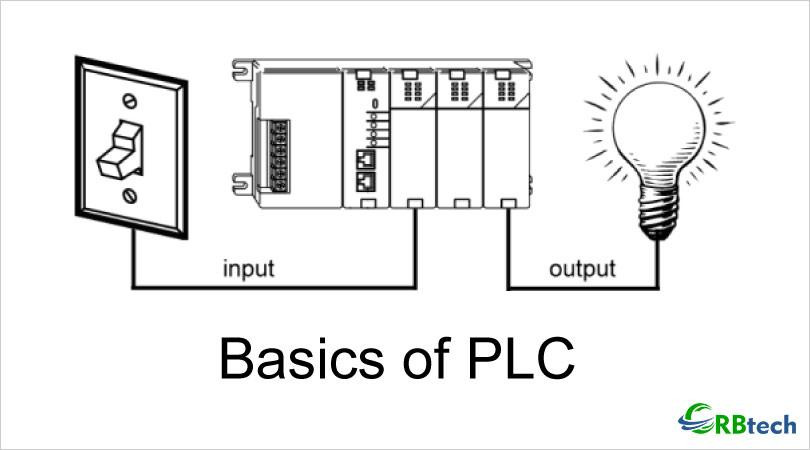

To explain it in a simple manner, a PLC happens to be a solid-state, programmable gadget that essays an important part in the control, monitoring and the automation of industrial resources. A PLC is capable of receiving inputs and delivering outputs similar to a PC. A microprocessor is placed in the center that does computations depending on the programmed code. PLCs serve as an electrical interface for the mechanical parts and support networking as a part of big industrial environments.

Programmable Logic Controllers (PLCs) have existed for more than 50 years now and have set up themselves as the favored hardware for industrial automation. A number of competitors have traveled the path in the form of PCs, micro-controllers etc. However, none have possessed the capacity to dent PLC’s reputation.

-

History:

The first ever PLC entered into the industrial environment in the 1960s and happened to be a variant of the widely utilized programmable controller. The requirement for reliable and adaptable control over relays in a space-canny way set off the development of PLCs. Not before long, PLCs took over Programmable Controllers, as they permitted reprogramming and re-usability as a part of the ladder logic.

PLCs come in different sizes, and for the most part occupy less space contrasted with rest of the industrial equipment. The PLC chassis could be open or shut, contingent upon the hardware specifications while every single electronic component is either mounted on PCBs or DIN rails.

- Functionality:

Programmable Logic Controllers function on the processing principle of scanning cycles. The methodology has stayed virtually unchanged for all PLCs. As special peripherals or hardware is included, the necessity for scanning cycles increases.

Here’s an approach to comprehend the scanning cycles. Initially, the software scans the I/O hardware modules, post power-up. The data contents are exchanged to the input’s image table while the data from the output table is sent to the output module.

The software program is eventually scanned, and processed as per the code. Outputs get reflected in the output table, post processing, and the related peripheral gadget (normally relay) is empowered. The extent of a PLC relies upon its I/O ability. The number of I/O points necessary are contrived by the System Engineer, contingent upon the load necessities. When the control machinery increases, additional I/O points would be needed which can be offered through expansion cards.

- Sections of PLC:

All PLCs comprise of four sections, each of them can be further divided into subsections.

- Power Supply Section

- CPU Module

- Processor section

- Memory section

- Program Software Section

- I/O Section

Those were the basics of PLC which you need to know, when you get started with it. Once you get well acquainted with them, you can move on and go for the advanced concepts of the same.