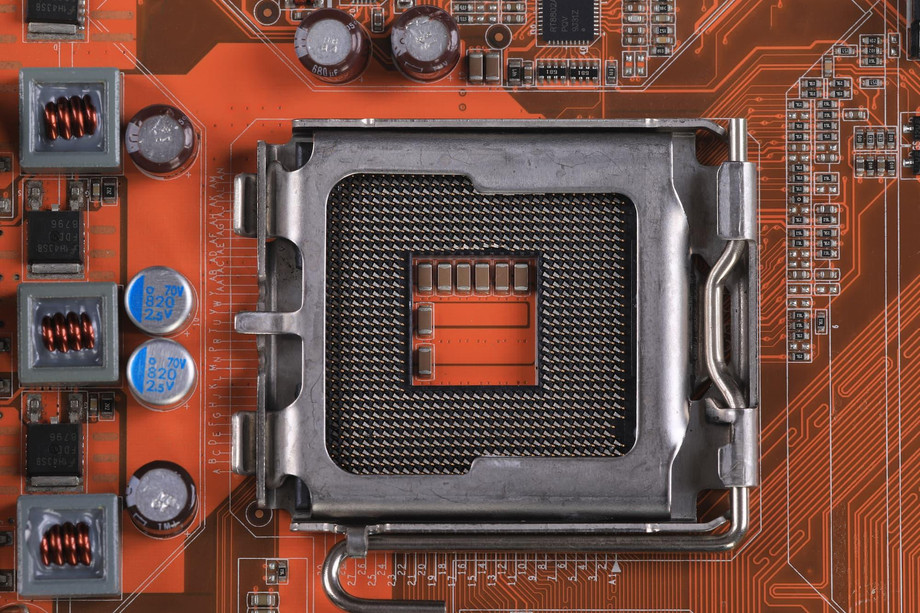

The silent workhorses of the contemporary world, embedded systems silently operate everything from pacemakers and thermostats to cars and aircraft. They are perfect for a wide range of applications due to their dedicated functionality and small size. Nonetheless, embedded systems frequently work in critical areas where failure can have dire repercussions, in contrast to personal computers that can restart themselves in the event of an error. This is the point in embedded hardware design where reliability is crucial.

Recognizing Reliability in Embedded Systems Design Patterns

Embedded systems design patterns contain reusable solutions to common issues that arise during development. In terms of reliability, some noteworthy patterns emerge:

-

Redundancy is the practice of using multiple copies of critical components to guarantee that operations continue even in the case of a breakdown. One way to do this is to replicate memory modules, processors, or even entire communication channels.

-

Failover: A failover system automatically switches to a backup component upon detecting a failure in the primary one. This minimizes downtime and ensures system functionality.

-

Error Detection and Correction (EDAC): EDAC techniques employ hardware mechanisms to identify and rectify errors that may occur during data transmission or storage. This helps maintain data integrity and prevent system malfunctions.

-

Watchdog Timers: These timers monitor the system's behavior and trigger a reset if a critical task fails to complete within a predefined timeframe. This helps prevent system hangs and ensures timely recovery.

Embedded Systems Examples and Reliability Considerations

Beyond design patterns, specific considerations in embedded hardware design for reliability vary depending on the application. Let's explore some real-world examples:

-

Industrial Control Systems: These systems manage critical processes in factories and power plants. Here, reliability is essential to avoid production downtime and potential safety hazards. Design considerations include using high-grade components with extended operating temperature ranges, implementing robust error handling routines, and employing redundancy for critical control functions.

-

Medical Devices: From pacemakers to insulin pumps, these devices directly impact patient well-being. Reliability is obviously a top priority. Designers must use components with proven reliability records, adhere to stringent medical device standards, and incorporate rigorous testing procedures to ensure flawless operation.

-

Automotive Electronics: Modern vehicles rely heavily on embedded systems for engine control, braking systems, and safety features like airbags. Here, reliability is crucial to preventing accidents. Design considerations include using components resistant to vibration and shock, employing electromagnetic shielding to minimize noise interference, and conducting extensive environmental testing to ensure proper functionality under various weather conditions.

Additional Factors for Reliable Embedded Hardware Design

Beyond design patterns and specific application considerations, there are several additional factors to prioritize for reliable embedded hardware design:

-

Component Selection: Choosing high-quality, well-tested components from reputable manufacturers is vital. Consider factors like operating temperature range, failure rates (mean time between failures, or MTBF), and radiation resistance, depending on the application.

-

Power Supply Design: A stable and reliable power supply is essential for consistent system operation. Consider using voltage regulators and filtering capacitors to mitigate voltage fluctuations and noise spikes.

-

Thermal Management: Heat buildup can damage components and lead to system instability. Ensure proper heat dissipation through heat sinks, fans, or by selecting low-power components.

-

Electromagnetic Interference (EMI) Shielding: External electromagnetic fields can disrupt system operation. Employ proper shielding techniques to minimize noise interference.

-

Design for Testability (DFT): Integrating features that facilitate testing during development and production phases is crucial. This allows for early detection and rectification of potential hardware issues.

-

Documentation: Thorough documentation of the design process, component selection rationale, and testing procedures is essential for future maintenance and troubleshooting.

Conclusion

By incorporating the principles outlined above, embedded hardware designers can create reliable systems that function flawlessly for extended periods of time, even in demanding environments. Embedded systems play a critical role in the smooth functioning of modern society, and their reliability ensures the safety, efficiency, and overall success of the applications they support. By prioritizing reliability throughout the design process, developers can create embedded systems that are truly dependable.

To Know More About embedded hardware design