Fleet Dispatch Software: Speed Up Operations and Lower Costs

Why Every Construction Business Needs Advanced Fleet Tracking—Now

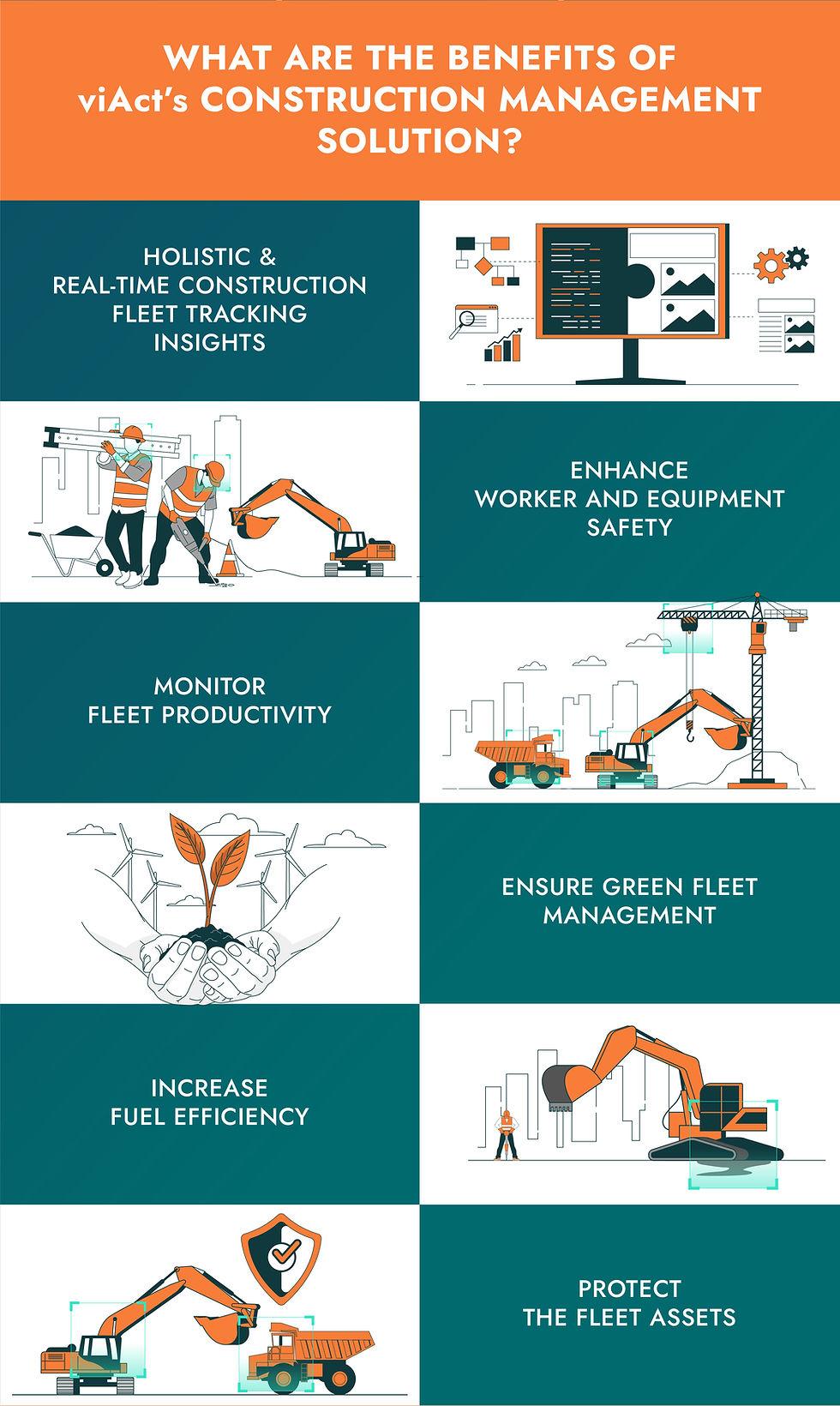

Advanced fleet tracking is essential for construction businesses today. You'll gain real-time vehicle monitoring - tracking construction equipment efficiently, enabling proactive maintenance and theft prevention. Route optimization can slash fuel costs by up to 30%, while efficient job scheduling maximizes productivity. Enhanced safety measures, including AI-powered driver monitoring, reduce accident risks and associated costs. Improved asset management provides accurate utilization data, supporting cost-reduction strategies. With increased operational efficiency and data-driven decision-making, you'll streamline processes and identify trends for better resource allocation. The benefits of advanced fleet tracking extend far beyond these highlights, offering groundbreaking potential for your construction business

Key Takeaways

- Real-time vehicle monitoring enhances safety, improves maintenance, and prevents theft.

- Advanced tracking can reduce fuel costs by up to 30% through route optimization and behavior monitoring.

- Efficient job scheduling maximizes productivity and minimizes downtime on construction sites.

- Proactive maintenance scheduling extends vehicle lifespan and reduces unexpected repairs and downtime.

- Data-driven insights enable better decision-making for resource allocation and operational efficiency.

real-time fleet data for construction

real-time fleet data for constructionReal-Time Vehicle Monitoring

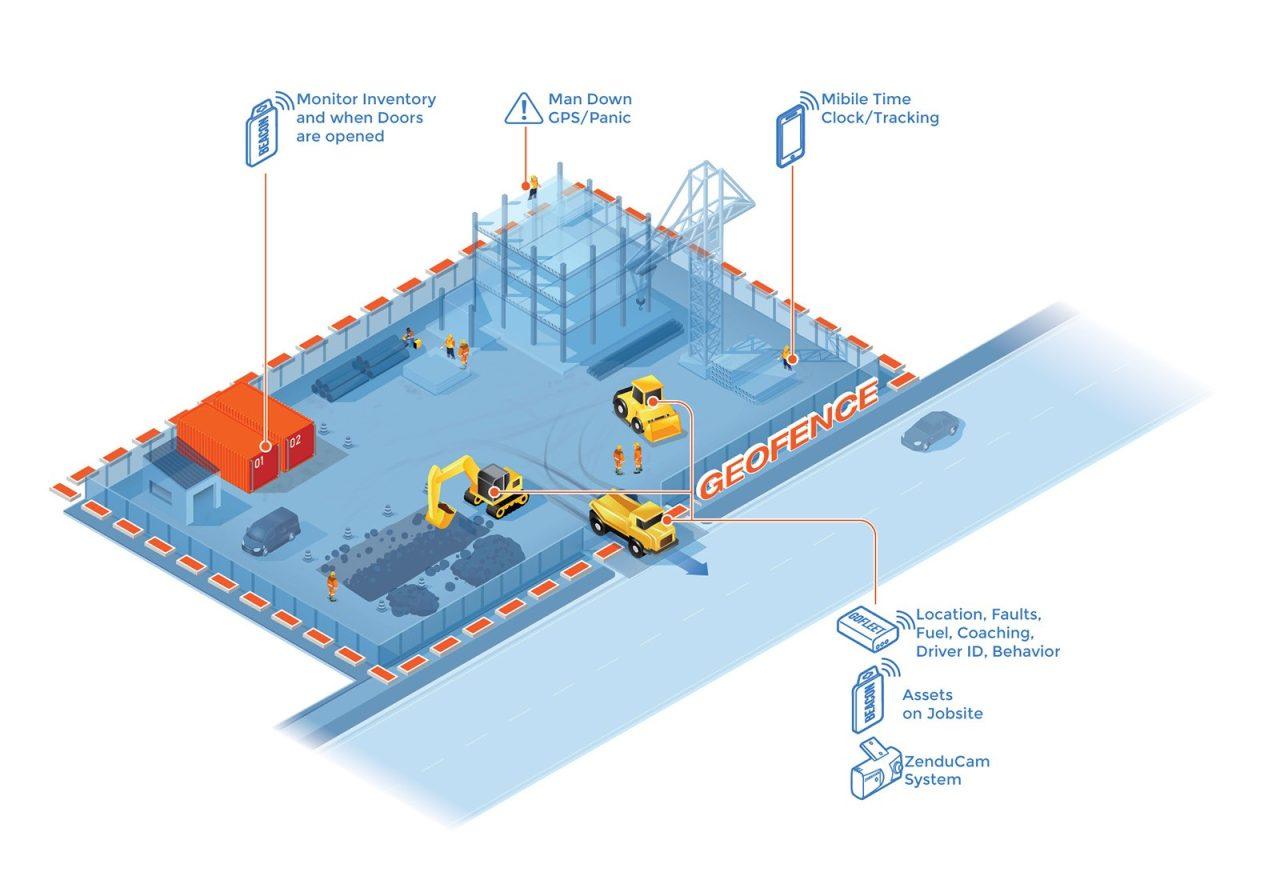

Tracking your construction fleet in real-time revolutionizes operational efficiency. By implementing advanced GPS technology, you'll gain instant access to essential vehicle health data, enabling proactive maintenance and reducing unexpected downtime. Real-time monitoring systems provide instant maintenance alerts, allowing you to address issues before they escalate into costly repairs.

Driver behavior tracking enhances safety and productivity, offering perspectives into speeding, harsh braking, and idle time. This data-driven approach improves fuel efficiency and reduces wear on your vehicles. Compliance tracking guarantees your fleet adheres to regulations, minimizing the risk of fines and penalties.

telematics for construction fleets

telematics for construction fleetsReal-time monitoring also serves as a powerful theft prevention tool, allowing you to quickly locate and recover stolen assets. Usage analytics - tracking construction equipment efficiently provide significant perspectives into vehicle utilization, helping you optimize fleet size and allocation. Seamless system integration with your existing software enhances overall operational efficiency

Improved customer communication becomes possible through accurate arrival time estimates. Performance metrics derived from real-time data allow you to set and track key performance indicators. Additionally, many insurance providers offer benefits for fleets with advanced tracking systems, potentially lowering your premiums and further improving your bottom line.

Cost Reduction Through Route Optimization

Route optimization in fleet tracking systems offers significant cost reduction opportunities for your construction business. You'll achieve fuel savings of up to 30% by minimizing unnecessary mileage and idle time, while simultaneously reducing vehicle wear through more efficient travel patterns. Optimized routes also enable more effective job scheduling, allowing you to complete more tasks per day and increase overall productivity.

Fuel Savings Potential

Consistently, fuel costs represent a considerable portion of operational expenses for construction businesses. By implementing advanced fleet tracking technology, you can greatly reduce fuel consumption and improve your operations. This technology provides real-time data on vehicle performance, driver behavior, and route efficiency, allowing you to make informed decisions (tracking construction equipment efficiently) that lead to substantial fuel savings

real-time fleet data for construction

real-time fleet data for constructionTo maximize your fuel savings potential, focus on these key areas:

- Idle time reduction

- Efficient route planning

- Driver behavior monitoring

- Vehicle maintenance enhancement

By addressing these factors, you can achieve exceptional fuel savings. Tracking technology helps you identify excessive idling. tracking construction equipment efficiently, allowing you to implement policies that reduce unnecessary fuel burn. Efficient route planning minimizes travel distances and avoids traffic congestion, directly impacting fuel consumption. Monitoring driver behavior enables you to address issues like aggressive acceleration and speeding, which can increase fuel usage by up to 33%. Regular maintenance, guided by real-time vehicle data, ensures peak engine performance and fuel efficiency

With advanced fleet tracking, you'll not only reduce fuel costs but also improve safety by promoting responsible driving habits and maintaining well-functioning vehicles. This data-driven approach to fleet management equips you to make strategic decisions that enhance your bottom line while prioritizing safety and efficiency.

Reduced Vehicle Wear

Your construction fleet's longevity directly impacts your bottom line, and advanced tracking technology. read more offers a powerful solution for reducing vehicle wear. By optimizing routes, you'll minimize unnecessary mileage, decreasing the overall strain on your vehicles. This translates to fewer repairs, extended vehicle lifespans, and significant cost savings over time

Advanced fleet tracking systems integrate vehicle diagnostics, providing real-time data on engine performance, tire pressure, and other critical components. This information allows you to implement proactive maintenance scheduling, addressing potential issues before they escalate into costly breakdowns. You'll reduce downtime and avoid unexpected repairs that can derail project timelines and budgets.

The system's ability to monitor driver behavior also contributes to reduced wear. By identifying and correcting harsh acceleration, braking, and cornering, you'll minimize unnecessary stress on vehicle components. This not only extends the life of your fleet but also enhances safety for your drivers and others on the road.

construction equipment fleet monitoring

construction equipment fleet monitoringEfficient Job Scheduling

Efficient job scheduling is a breakthrough for construction businesses leveraging advanced fleet tracking technology. By optimizing routes and allocating resources more effectively, you can greatly reduce costs and improve project timelines. Advanced fleet tracking systems provide real-time data on vehicle locations, traffic conditions, and job site requirements, enabling you to make informed decisions that enhance team collaboration. tracking construction equipment efficiently and operational efficiency

Implementing efficient job scheduling through fleet tracking offers several key benefits:

- Reduced fuel consumption: Optimized routes minimize unnecessary mileage

- Improved resource allocation: Assign the right equipment and personnel to each job

- Enhanced productivity: Minimize downtime and maximize on-site work hours

- Increased safety: Avoid overloading drivers with unrealistic schedules

Enhanced Safety Measures

Advanced fleet tracking systems offer real-time driver monitoring. real-time fleet data for construction capabilities, allowing you to assess driver behavior and performance instantly (tracking construction equipment efficiently). You'll gain important observations into speeding, harsh braking, and other potential safety risks, enabling prompt corrective action. Additionally, these systems often incorporate accident prevention technologies, such as collision warning systems and lane departure alerts, greatly reducing the likelihood of on-road incidents

Real-Time Driver Monitoring

Safety stands at the forefront of modern fleet management. Real-time driver monitoring boosts your construction fleet's safety protocols by providing instant observations into driver behavior and promoting driver accountability. This technology allows you to track and analyze vital metrics that directly impact safety and efficiency.

Implement real-time driver monitoring to:

fleet tracking systems for construction

fleet tracking systems for construction- Detect and alert on dangerous driving patterns, such as harsh braking or rapid acceleration

- Monitor speed limit compliance across various road types

- Identify instances of distracted driving through AI-powered camera systems

- Track hours of service to guarantee compliance with regulations and prevent driver fatigue

By leveraging this data, you'll be able to address safety concerns proactively, reducing the risk of accidents and associated costs. Real-time monitoring also enables immediate intervention when unsafe behaviors are detected, potentially averting incidents before they occur.

Furthermore, driver accountability increases as operators become aware of continuous monitoring. tracking construction equipment efficiently. This awareness often leads to self-correction of risky behaviors, resulting in a safer fleet overall. By implementing real-time driver monitoring, you're not only protecting your assets and employees but also optimizing operational efficiency and reducing liability exposure

Accident Prevention Technologies

Numerous accident prevention technologies are revolutionizing safety measures in construction fleet management. These advanced systems utilize predictive analytics to identify potential hazards before they escalate into accidents. By analyzing historical data and real-time information, you can anticipate high-risk situations and take proactive measures to mitigate them.

One key component of accident prevention is the monitoring of driver behavior. Advanced telematics systems. tracking construction equipment efficiently track factors such as harsh braking, rapid acceleration, and excessive speeding. This data allows you to identify patterns and address risky behaviors through targeted training programs. Additionally, collision avoidance systems use sensors and cameras to detect obstacles, alerting drivers to potential dangers and even automatically applying brakes when necessary

Fatigue management technologies monitor drivers' alertness levels, detecting signs of drowsiness and providing timely warnings. Lane departure warning systems and stability control mechanisms further enhance vehicle safety. By implementing these state-of-the-art technologies, you'll greatly reduce the likelihood of accidents, protect your workforce, and minimize costly downtime. The result is a safer, more efficient fleet operation that enhances your bottom line while prioritizing the well-being of your employees and the public.

Improved Asset Management

Construction businesses can greatly enhance their asset management through advanced fleet tracking systems. These technologies provide real-time data on equipment utilization and maintenance tracking, enabling you to optimize your fleet's performance and reduce operational costs.

With advanced fleet tracking, you'll gain: - tracking construction equipment efficiently

- Precise equipment location data

- Accurate usage hours and idle time metrics

- Automated maintenance scheduling alerts

- Detailed fuel consumption reports

real-time tracking for construction fleets

real-time tracking for construction fleetsBy leveraging this information, you can make data-driven decisions to improve asset allocation and maximize productivity. You'll be able to identify underutilized equipment, reducing unnecessary rental costs and improving overall fleet efficiency.

Maintenance tracking features guarantee timely servicing, reducing the risk of unexpected breakdowns and extending equipment lifespan. This proactive approach minimizes downtime and enhances workplace safety by preventing equipment failures on job sites.

Advanced fleet tracking systems also provide significant observations into operator behavior, allowing you to identify areas for improvement in equipment handling and safety practices - fleet tracking systems for construction. By analyzing this data, you can implement targeted training programs to enhance operator skills and reduce the risk of accidents

Ultimately, improved asset management through advanced fleet tracking leads to increased profitability. tracking construction equipment efficiently, enhanced safety, and more efficient project completion

improving fleet operations in construction

improving fleet operations in constructionIncreased Operational Efficiency

Three key factors contribute to increased operational efficiency through advanced fleet tracking in construction businesses: real-time visibility, data-driven decision-making, and automated processes. Real-time visibility allows you to monitor your fleet's location, status, and performance, enabling quick responses to issues and enhancing route planning. This visibility directly impacts employee productivity, as you can identify and address inefficiencies promptly.

Data-driven decision-making equips you to analyze historical and current fleet data, uncovering trends and patterns that inform strategic choices. By leveraging this information, you can improve resource allocation, reduce downtime, and enhance overall operational performance. This approach helps you meet project timelines more consistently and efficiently.

Automated processes streamline various aspects of fleet management, such as maintenance scheduling, fuel monitoring, and compliance reporting. These automations reduce manual tasks, minimize human error, and free up significant time for your team to focus on core construction activities. Additionally, automated alerts for vehicle maintenance and safety issues guarantee that your fleet remains in peak condition, reducing the risk of unexpected breakdowns and enhancing overall safety on job sites.

Data-Driven Decision Making

While intuition and experience play a role in fleet management, data-driven decision making has become essential for construction businesses seeking to optimize their operations. Advanced fleet tracking systems provide a wealth of data analytics that can reshape your decision-making process. By leveraging this information, you'll be able to make informed choices that enhance efficiency, reduce costs, and improve safety.

Data analytics and decision support tools offer several key benefits: - tracking construction equipment efficiently

- Real-time observations into vehicle performance and driver behavior

- Predictive maintenance schedules based on actual usage patterns

- Route optimization for fuel efficiency and timely deliveries

- Automated compliance reporting for regulatory requirements

With these tools at your disposal, you can identify trends, spot anomalies, and anticipate potential issues before they become costly problems. You'll be able to allocate resources more effectively, reduce downtime, and minimize safety risks. By basing your decisions on hard data rather than guesswork, you'll streamline operations and gain a competitive edge in the construction industry.

Implementing data-driven decision making through advanced fleet tracking isn't just about improving your bottom line—it's about creating a safer, more efficient work environment for your entire team.

Frequently Asked Questions

How Long Does It Take to Implement a Fleet Tracking System?

You can implement a fleet tracking system in 2-4 weeks. The timeline varies based on fleet size and complexity. You'll see tracking system benefits quickly, including improved safety and efficiency. Prioritize thorough training for best results.

Can Fleet Tracking Work in Areas With Poor Cellular Coverage?

Ever wondered about tracking in remote areas? You'll be pleased to know that fleet tracking can work with poor cellular coverage. Satellite tracking guarantees connectivity, while offline capabilities store data for later transmission (tracking construction equipment efficiently). It's a reliable, safety-enhancing solution for your operations

What Privacy Concerns Should Be Addressed When Implementing Fleet Tracking?

You'll need to address data security to protect sensitive information and obtain employee consent. Implement encryption, secure access controls, and clear privacy policies. Communicate the safety benefits and efficiency gains to gain workforce buy-in for fleet tracking implementation.

How Does Fleet Tracking Integrate With Existing Construction Management Software?

You'll achieve seamless data synchronization between fleet tracking and construction management software through API integrations - how to track construction fleets. Guarantee software compatibility for real-time updates on vehicle locations, job progress, and resource allocation - tracking construction equipment efficiently. This integration enhances operational efficiency and improves site safety

Are There Any Legal Requirements or Regulations for Using Fleet Tracking?

You'll need to take into account legal implications and regulatory compliance when implementing fleet tracking. Make sure you're adhering to data protection laws, obtaining driver consent, and following local regulations on GPS tracking to maintain safety and efficiency standards.

Conclusion

tracking construction equipment efficiently

tracking construction equipment efficientlyDon't let your construction business fall behind the eight ball. Advanced fleet tracking is no longer a luxury—it's a necessity for staying competitive. You'll optimize routes, enhance safety, manage assets efficiently, and elevate operational productivity. With real-time data at your fingertips, you're enabled to make informed decisions that drive profitability. Adopt this technology now to streamline operations, reduce costs, and position your company for sustainable growth in the constantly changing construction industry.