Introduction –

In the realm of construction and interior design, plywood has long reigned as the go-to material for a variety of applications. However, a revolutionary alternative has emerged in recent years: polygranite sheets. As the demand for sustainable, durable, and versatile materials grows, polygranite sheets have captured the attention of industry professionals and consumers alike. In this blog, we will delve into the world of plywood manufacturing and explore the advantages that polygranite sheets bring to the table. By highlighting keywords such as plywood manufacturers and polygranite sheets, we will shed light on the transformative potential of this new material.

The Dominance of Plywood manufacturers: -

Plywood, a composite material made from thin layers of wood veneers, has long been the preferred choice in the construction and furniture industries. Plywood manufacturers have dominated the market, meeting the demand for a reliable and cost-effective material. However, there are certain limitations inherent in plywood that have paved the way for alternative solutions.

- Moisture Sensitivity: Plywood is susceptible to moisture, which can lead to warping, delamination, and reduced structural integrity. This limitation restricts its application in environments prone to humidity, water exposure, or extreme weather conditions.

- Environmental Impact: Traditional plywood manufacturing processes often involve the use of harmful chemicals, such as formaldehyde-based adhesives. This poses health risks for both workers and end-users and contributes to environmental degradation.

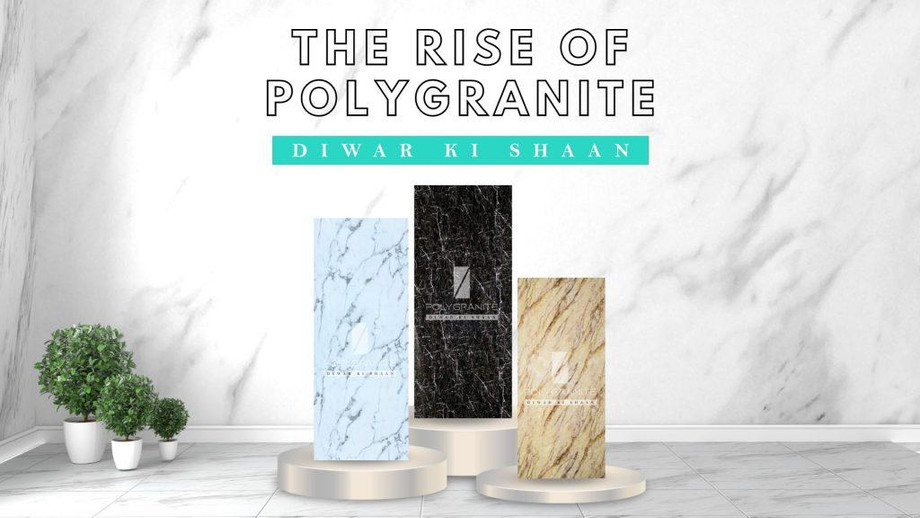

Polygranite Sheets: A Game-Changer: -

Polygranite sheets have emerged as a revolutionary alternative to plywood, offering numerous advantages and addressing the limitations associated with traditional materials. These innovative sheets are composed of a blend of polymers, creating a durable and versatile material with exceptional performance characteristics.

- Water Resistance- Polygranite sheets are inherently waterproof, making them impervious to moisture damage. This quality expands their application possibilities, allowing them to be used in bathrooms, kitchens, and outdoor environments without concerns of warping or degradation.

- Sustainability- In contrast to plywood manufacturing, the production of polygranite sheets often involves the use of recycled materials. Furthermore, their longevity and resistance to wear and tear contribute to reduced waste and the promotion of sustainable practices.

- Low Maintenance- Polygranite sheets require minimal upkeep compared to plywood. They do not need to be sealed, painted, or stained, saving both time and resources. Their resistance to mold, mildew, and stains ensures a long-lasting, attractive surface with little effort.

- Versatility and Aesthetics- Polygranite sheets come in a wide range of colors, patterns, and finishes, offering endless design possibilities. They can mimic the appearance of natural stone, wood, or other materials, providing an aesthetic appeal that rivals traditional options.

The Rise of Polygranite Sheets: -

The plywood manufacturing industry is witnessing a gradual shift as polygranite sheets gain recognition and market share. Architects, interior designers, and consumers are becoming increasingly aware of the advantages that polygranite offers. Some key factors contributing to the rise of polygranite sheets include: -

- Awareness of Environmental Impact- The push for sustainable practices and environmentally friendly materials has encouraged professionals and consumers to seek alternatives to plywood. Polygranite sheets, with their recycled content and reduced waste, align with these values.

- Improved Performance- The superior water resistance, durability, and low-maintenance qualities of polygranite sheets make them an attractive option. They offer enhanced functionality and performance compared to plywood, particularly in moisture-prone environments.

- Design Flexibility- Polygranite sheets provide a vast array of design possibilities, enabling architects and designers to push creative boundaries. Their ability to mimic the appearance of various materials allows for customization and the creation of unique spaces.

Conclusion –

As the construction and interior design industries evolve, the demand for innovative, sustainable, and high-performing materials continues to grow. Plywood manufacturers, who have long dominated the market, now face competition from the revolutionary alternative— polygranite sheets. With their superior water resistance, low maintenance, sustainability, and design versatility, polygranite sheets are transforming the industry. Architects, interior designers, and consumers alike are recognizing the benefits of this new material, which addresses the limitations of traditional plywood. As awareness spreads and technological advancements continue, polygranite sheets are poised to reshape the manufacturing landscape, offering a brighter and more sustainable future for the construction and design sectors.