An Overview of Needle Valves

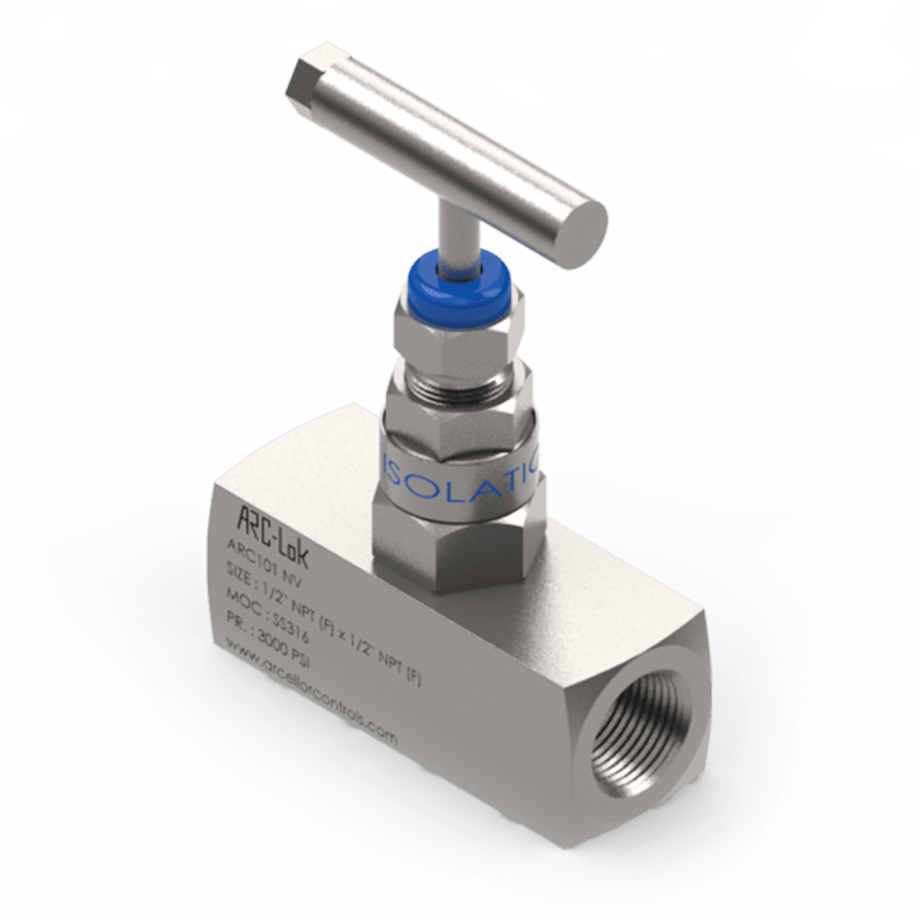

Instrumentation valves, like needle valves, are popularly known as plunger valves. These are essential for regulating fluid flow and pressure and accurately controlling the fluid flow rate and pressure in the pipeline. Needle valves offer fine actuation and adjustment, offering extreme flow control. Needle control valves are essential for applications involving high-pressure drop and low flow rates from the inlet to the outlet. Needle valves can also be used for shutting down or cutting-off fluid flow. These valves have a working mechanism similar to piston check valves.

Needle valve functioning

Needle control valves open and close the orifice between the outlet and inlet through the motion of the tapered needle. The needle of the valve directly connects to the stem or plunger. It further connects to the handle converting rotary motion to back-and-forth motion using the internal bonnet thread.

Once the handle receives the rotary motion converting it into the back and forth motion, the orifice closes and opens. The system also has a locking nut at the bonnet’s top, preventing the total plunger from unscrewing from the internal thread. When the instrumentation valve’s needle goes down, it makes contact with the valve seat providing leakage-proof fluid shut-off in the pipeline. The bonnet connects to the valve housing with a screw system.

The instrumentation valve’s actuation is controlled by automatic or manual handle rotation. Automated needle check valves are usually operated using an electric motor. They can also utilize hydraulic systems. The motor offers precise position control of the stem in the valve bonnet per the external requirement.

How to select needle valves?

The selection of needle control valves depends on the following four factors as follows:

- Valve material: Brass and stainless steel needle valves are the most common needle valve materials. Needle valves of brass are perfect in highly corrosive environments like potable water flow systems. Stainless steel needle valves are essential for applications involving exposure to acids and seawater. Stainless steel and brass needle valves can tolerate high temperatures.

- Orifice and port size: Needle control valves have extensive varieties of orifice and port sizes. The common port sizes fall in the range of 2mm to 12 mm. Selecting an instrumentation valve with an accurate orifice and port size increases the efficiency of the flow and also prevents system leakages.

- Pressure ratings: The selection of the needle valve depends on the pressure ratings. A high-quality needle valve can handle a pressure range of up to 415 bars. However, some needle valves can also handle pressure ranging up to 690 bars.

- Temperature ratings: Needle control valves are essential for an extensive temperature range. These valves can handle high and low temperatures per sealing material and sustainability.

Applications of needle control valves

- Needle control valves find application in automatic combustion systems.

- These valves ensure effective flow regulation.

- The needle valves are essential in pressure pump governors for minimizing fluctuating effects.

- These valves are essential for gradually stopping the flow.

- They are essential for turning the system on and off with throttle.

FAQs

- How are needle valves beneficial?

Stainless steel needle valves offer precise and slow flow control, ensuring smooth fluid flow.

- Why are needle valves essential?

S.S. needle valves help the regulation of fluid flow in the system. It comes with a small plunger like a tapered end needle.

- Why are needle valves essential in pneumatic systems?

In pneumatic systems, needle control valves are crucial for reducing the fluid flow rate.

Final thoughts

Arcellor Controls (India) is a leading needle valve manufacturer in India. The company features a range of instrumentation fittings like flanges, instrumentation valves, flange types, types of valves in instrumentation condensate pots, and more. Explore the website today!