Shipping is one of the most expensive aspects of running a small business. Whenever you transport your order in a larger-than-needed packing, keep in mind that you are paying more amount to the transport or courier service provider. Imaging such an extra loss on daily basis and calculated yearly by just adding 10%-20% extra of your courier or shipment.

Reasons for Over Costing in Shipping Costs.

It is human physiology that the small things are always overlooked and the same thing happens in packaging material costs which also happens in courier and shipping costs. With carrier delivery rates rapidly increasing due to crude oil prices, it’s more important than ever to re-consider their impact on logistic costs. So accurate size of your packaging material can greatly reduce courier or shipping costs. We, being in logistic operations perform a functional inspection of packaging as part of our ROI analysis; we found many shippers are packing over one-quarter of their orders into larger boxes.

So what we should do is always pack orders in the correct size box which may cover the contents. Yet too frequently, many companies are paying redundant costs to transport empty space.

Shipping orders in comparatively larger boxes was not an issue in history due to the calculation of freight being done by weight only. But now, all logistics and courier service providers consider both physical weight and dimensional weight. Now whichever is higher in physical weight and dimensional weight is being charged, so using the wrong size box has come veritably precious.

Imagine, the order packer selects a larger packaging than necessary to pack the item for the said order. That payload will increase the shipping cost by the transporter due to the increased size of the box.

Example of high redundant Shipping Costs.

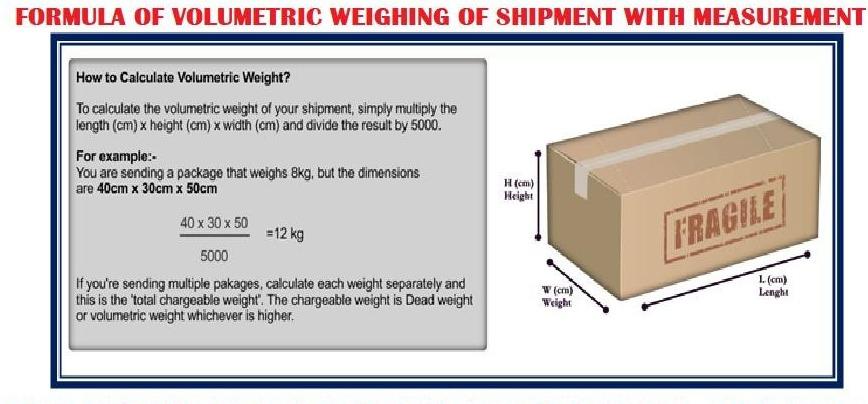

Just for an example, consider a 40 cm x 30 cm x 50 cm as three dimensions and its dimensional weight will be 12kg which comes by multiplying all three measurements and dividing by 5000. Using this standard industry dimensional factor, if you fill a 10 kg load or items for shipment, you are potentially paying 2 kg extra to your transporter.

How to Reduce Logistics or Shipping Costs?

- There are a few things you can do to reduce your shipping costs. You should reduce the prevalence of orders being packed in larger-than-necessary boxes by broadening your package types and sizes. Shippers may need to work with their box merchandisers to give a more expansive selection of box sizes than was necessary with weight-grounded shipping alone.

- Include 2 & 4 box sizes larger and 3 & 5 packaging sizes lower than your average order size to handle outlier packages.

- Also, paying a bit more for the packaging demanded to fit your particular item could equate to several times that quantum in shipping cost savings. To further reduce shipping costs of packaging by cardboard/ padded envelopes and polybags.

- There are many shipping calculators (websites) available online. The most popular is probably UPS’s Calculate Shipping. This tool can help you find the shipping costs for a variety of items, including small and large packages.

- A little-given fact is that Postal Service provides free boxes, envelopes, and polybags for orders packed via numerous of its services, saving you a fresh 25 to 75 cents per package.

- Use Shipping Services that Offer Discounts. Some shipping services offer discounts for large orders. For example, US Postal Service offers a Priority Mail Flat Rate Box rate for packages overweight or size.

- Stylish practices in cost-effective packaging vary by a company’s assiduity, products, shipping conditions, and more. CLS has helped numerous companies estimate and optimize their packaging options and reduce labor costs by automating order quilting and shipping processes.