Industrial Salt Manufacturing Process and Precautions

Earlier almost all types of industrial salt were produced from the process of seawater evaporation. Mostly, it was produced where the climate is dry and summer remains for a long period. But, with emerging changes, there are several processes evolved for the production of industrial salt. Today, there are many industrial salt manufacturers in India that make use of one or another method to produce quality salt. In this post, we will learn these manufacturing processes along with the precautions that are necessary to be taken while producing Industrial salt.

Methods used to produce Industrial Salt -

- Solar Evaporation Method for Industrial Salt production

This is one of the oldest methods for the production of salt. This process came into existence when salt crystals were first noticed in seawater. Its practical use is seen where the evaporation rate is more than the precipitation rate, either for an extended period or annually or where you find steady prevailing winds.

In the making of solar salt production, in shallow ponds, there would be capturing of saltwater where the sun will evaporate the maximum amount of water. Then, concentrated brine will precipitate the salt which will then be further collected by a mechanical harvest machine. Any kind of impurities will be drained off before harvesting. In this process, basically, 2 types of ponds are being used, one the concentration pond where salty water from a salt lake or ocean is collected. Two, crystallizing ponds where crystallized salt already exist for the salt evaporation process.

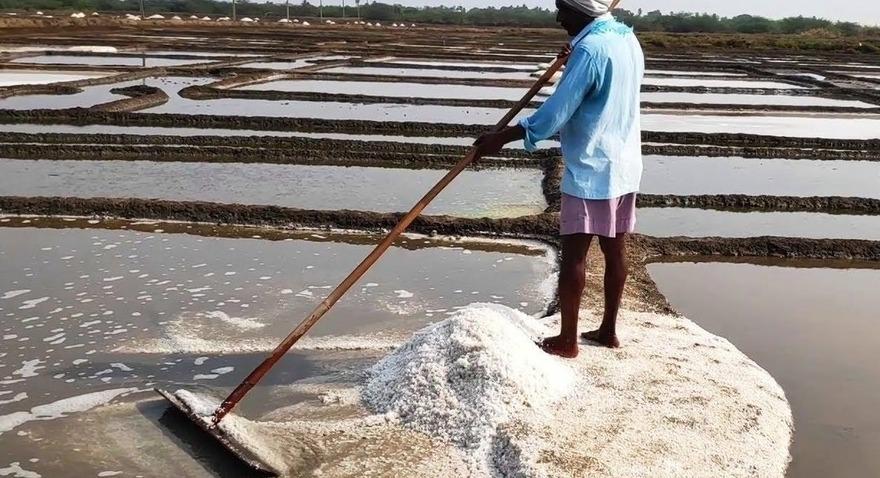

Check out these visuals to better understand the manufacturing of salt in concentration & crystallizing ponds.

- Concentration Ponds

- Crystallizing ponds

The range of crystallizing ponds is from 40 to 200 acres with a foot thick salt floor resulting from the years of deposition. During these 4 to 5 months of the salt-making season, brine flows continuously in these ponds. It is a saturated brine solution that contains as much salt so that pure salt crystallizes out and the remaining water evaporates.

The solar evaporation method is particularly amenable to several industrializing countries that are located in Asia/Pacific and Africa/Mideast regions where low precipitation levels and high evaporation rates are required. In fact, affluent countries including the US comprises man made saltwater ponds so that salt is extracted via using bulk loading equipment.

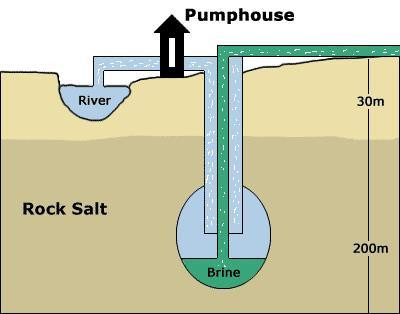

- Industrial Salt Manufacturing from Rock Salt

The beds of rock salts are quarries or mined by the usual extraction process. However, the thickness, depths, and local conditions also matter. The mined rock is dissolved sometimes & salt is produced by the brine treatment. In when the rock salt is manufactured with high purity degree, the salt is usually marketed, screened, and grounded without any further process. The salt typically mined in large lumps that are first crushed and then finely ground & screened by size via several grades. Then, salt is bulk loaded into barges, hoppers, or trucks for further handling.

Bulk handling is mostly facilitated by the help of anti-caking agents that ensure salt to be stored outdoors and uncovered without turning into hard mass again.

China, the United States, India, Germany are some of the top countries that make use of this method for the manufacturing of rock salt. However, China ranks on the top among these listed countries.

- Industrial Salt Manufacture from brines and Seawater

We understand that only a specific quantity of salt will dissolve in water at a given temperature. This state is called saturation where you can’t add more salt in the water as it won’t dissolve further. When the aqueous solution of different salt gets evaporated, then each salt precipitates as it reaches the saturation point of the solution. In this way, different salts present in the seawater will precipitate at different time intervals that lead to the formation of layers on the bottom of the pool. For many brines and seawater, the order of deposition is magnesium chloride, potassium magnesium chloride, calcium carbonate, magnesium chloride, calcium sulfate, and sodium chloride.

The most common table salt you can see in the market results from salt brines, while gourmet or specialty salts are still produced from seawater evaporation. When it comes to salt production from brines, China is again the largest producer which is followed by the US. Only six percent of salt of the 220 million tons is best for human consumption.

-

Precautions to necessary while manufacturing industrial salt

Although normal handling of industrial salt won’t lead to any serious health hazards or effects, yet for safety, it's good if good laboratory practices are being followed-

- The working area must have sufficient exhaust ventilation. In order to ensure minimization of airborne exposure, regularly vacuum dust from the surroundings.

- Avoid skin contact and make sure you are wearing protective gloves in hands and clothing.

- Avoid eye contact and do not forget to wear eye protection goggles if eye contact is likely to occur.

- Last, but not least store sodium chloride in a well-ventilated, dry and cool area and keep it in a closed container securely. Also, it should be kept away from excessive heat.

Know the widely acceptable method for salt production!

Though, all these three methods are apt at their place and help in the rich quality of salt. But, the widely used method that still stands apart from others is “Solar Evaporation Method”. Several companies make use of this method as it’s quite easy, safe and salt quality is unbeatable. Moreover, this won’t cost you high and is easily affordable within your budget.

Who is best renowned for Industrial salt making?

If you are looking for a reputed company for the production of edible and Industrial salt, GHCL is a one-stop destination for you. We are counted amongst the top-notch iodized salt manufacturers in India because we never compromise with the quality of salt. Our professionals follow the best ways in order to make a good quality salt. For further information, you can visit our website or talk with our teammates!