The need may indeed be the mother of the invention, but it still leaves the inventor, not to mention the designer, the developer, and the manufacturer, in need of a great deal of help. More and more, three letters spell out that message and bring rescue innovators to their needs, but they are not sure about the ideal machining components, as you might have guessed. CNC metal machining has several advantages – boosting efficiency and precision while reducing waste in your shop – but their versatility is one of their most significant advantages.

Here are among the most prominent applications for CNC metal machining and how you should use a CNC router or CNC plasma to improve your work from initial programming to final cutting.

Signage

If you are making a temporary 2D project or a more complex 3D signage component, a CNC metal machining can quickly and cleanly get the job done. CNC routers can deal with a wide variety of materials, including foam, wood, plastic, acrylic, aluminium, brass, and more.

Machines featuring a vision system will boost efficiency and accuracy for users who need to register a tool path when making signs or carvings quickly. Creating ADA-compliant signage also is crucial for many modern sign shops, necessitating a CNC machine capable of intelligently getting results with tactile text, braille, character spacing, and more to comply with the complex ADA signage regulations.

Electrical Discharge Machining (EDM) Applications

EDM machines produce sparks that burn the unwanted metal away. Through CNC metal machining, EDM machining can be done in two ways; vertical EDM, which requires an electrode of the same size and shape as the cavity to be carved; and wire EDM, which is used to create punch and die combinations for die sets used in the metal manufacturing industry.

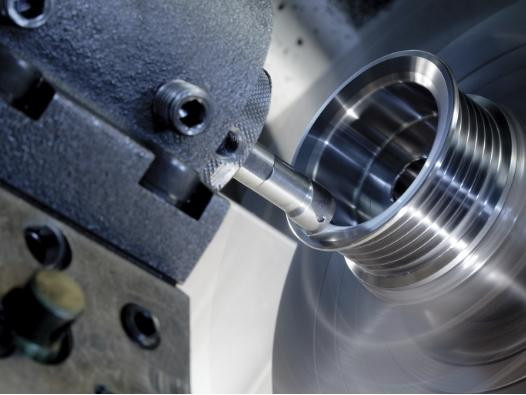

Metal Removal Industries

CNC metal machining is incredibly helpful in metal removal industries such as the automotive, aerospace, and jewellery industries. This technology removes excess metal from raw materials to achieve the desired final product. CNC machines may also produce moulded products in the manufacturing sector, including threaded, rounded, rectangular, square, or even three-dimensional products.

Industries for Fabricating Metals

In many industries, thin plates such as steel plates are needed for several purposes; CNC metal machining operations are carried out on such plates in the manufacturing industry. In these industries, CNC devices are used for scissor, flame or plasma cutting, punching, laser cutting, shaping, welding, and many other applications. CNC lasers and CNC plasma cutters are widely used to get the plates to their final form. CNC turret punching presses are used to cut holes in all plates' sizes.

CNC metal machining is still commonly used in the woodworking CNC machine shop for various operations such as routing and milling, and drilling. CNC technology is also used in a variety of lettering and engraving schemes. CNC devices for the electrical industry are also available, such as CNC coil winders and CNC terminals, and soldering machines.