Professional PCBA Manufacturing Service by Hitech Circuits in China

As the demand for electronic devices continues to grow, understanding the complexities of Printed Circuit Board Assembly (PCBA) has become increasingly crucial. This comprehensive guide will provide an in-depth look at the PCBA process, the types of PCB assembly, and the various techniques and tips involved. We will also explore the meaning of PCBA in electronics, ensuring you have a thorough understanding of this vital component.

PCBA stands for Printed Circuit Board Assembly. Up to this meaning, it’s all fine. But the real problem starts right from here. Many, in fact, most people don’t understand the true meaning and purpose of the PCBA. And many would even confuse it with the PCB.

So, we decided to write on what is PCBA. Of course, it has a close connection with the Printed Circuit Board (PCB). A PCB refers to an electronic pad designed to transmit electronic signals while dissipating the heat generated due to the digital transmission.

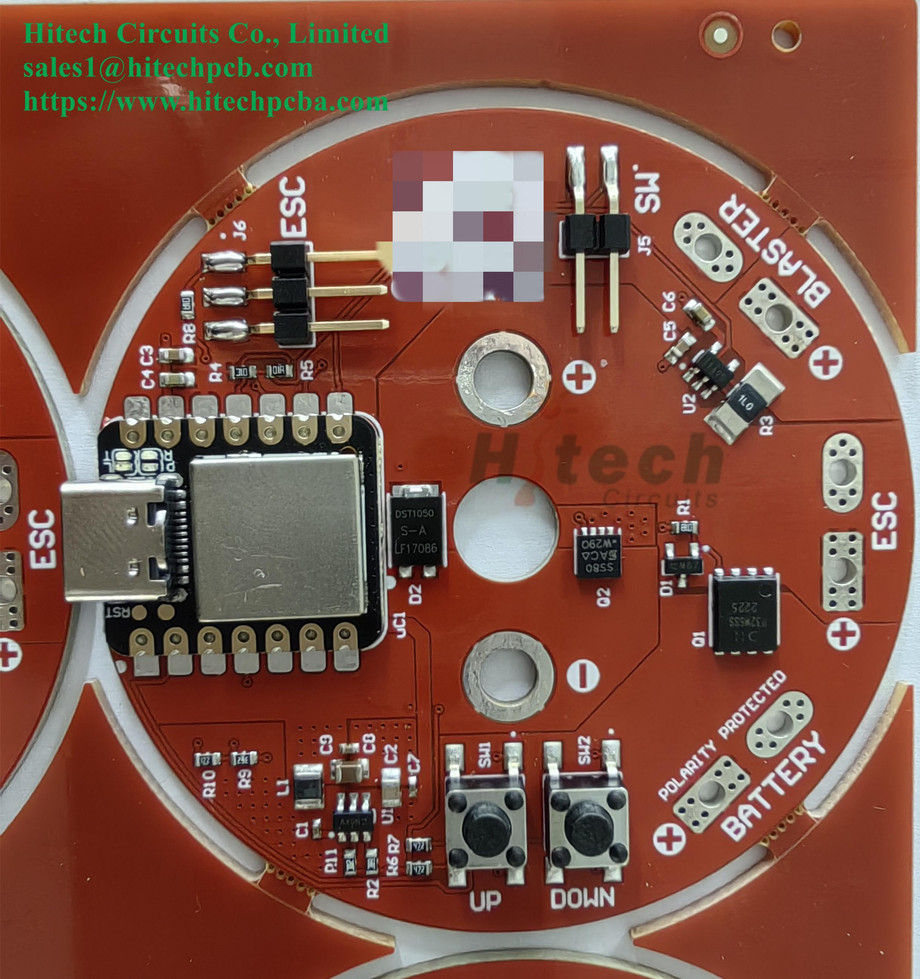

And the PCBA refers to the complete electronic board after all of its components are assembled completely. It has several incredible benefits that make it a much sought-after element in the communicating and electronics industry.

Printed Circuit Board Assembly Services

Printed Circuit Board Assembly Service ( PCB Files & BOM List, please send to sales1@hitechpcb.com ( Fast Quote )

Printed Circuit Board Assembly is a process that requires knowledge not just of Printed Circuit Board components and assembly but also of printed circuit board design, Printed Circuit Board fabrication and a strong understanding of the final product. Circuit board assembly is just one piece of the puzzle to delivering the perfect product the first time.

Printed Circuit Boards (PCBs) are across many industrial and consumer electronics, used in products ranging from remote controls to military weaponry. The versatility of PCBs comes from their lightweight, compact, and flexible construction, which can be adapted to suit circuits of any complexity. Though PCBs are relatively commonplace, their complexity makes it critical to source new circuit boards from reliable suppliers. Printed Circuit Board Assembly services harness these complexities.

Hitech Group offers comprehensive Printed Circuit Board Assembly services that help our customers fully realize their designs. We have extensive experience working with customers in a broad range of highly innovative industries, including Communication, Aerospace & Defence, Automotive, Industrial control, Medical equipments, Oil & Gas, Security, and so on.

What does PCBA Stand for in Electronics?

PCBA stands for Printed Circuit Board Assembly. It refers to the process of soldering electronic components to a printed circuit board (PCB) to create a functional circuit. The PCB is essentially the backbone of electronic devices, providing a solid foundation for components and facilitating connections between them. The assembly process involves soldering components to the board, and this completed assembly is then referred to as PCBA.

We offer the following PCB assembly services:

Quick-turn prototype printed circuit boardassembly

Turn-key printed wiring board assembly

Partial turn-key PCB assembly

Consignment assembly

RoHS compliant lead-free PCB assembly

Non-RoHS assembly

Conformal coating

Final box-build and packaging

The process of PCBA manufacturing

Electronic Components sourcing – PCB fabrication- SMT Patch – DIP plug-in – board Assembly testing – Finished product assembly

PCB Assembly requires electronic components and consumables

Printed Circuit Board, Electronic Components, Solder Wire, Solder Paste, Welding Rod, Solder Preform (depending on welding type), Scaling Powder, Welding Platform, Wave Soldering Machine, SMT Equipment, Testing Equipment

PCB manufacturing

Hitech Group provides a full set of PCBA manufacturing and part of PCB assembly manufacturing. In the full range of PCB assembly manufacturing, we handle PCB production, material procurement, online order tracking, incoming material certification/quality inspection, and final assembly. In some PCB manufacturing, you can order PCB and some materials by yourself, and we complete other parts.

Please feel free to contact sales1@hitechpcb.com if you have any PCB needs.

For more, please visit https://hitechcircuits.com/pcb-assembly/printed-circuit-board-assembly-services/