The estimated value of global face mask market is $9052.1 million. And these face masks keep you safe from influenza, mumps, measles, chickenpox, and COVID too. So, this is the best time to set up your business, if you are planning on one. But the cost of setting up your business does not solely depend upon market value, machinery also plays a part. So there are organizations that are willing to do the research, manufacturing, testing, shipping and delivery to you into lots and you can sell it under your brand. OEM face masks are a convenient option to choose from.

Research and development in the field

The research tells you that a face mask is categorized into several classes according to the region, material, usage and distribution channel. By material, it is bifurcated into cotton, polypropylene, and others. By nature, it is categorized into reusable and disposable. All over the world, the purpose of research is to develop a tested product which would be effective in filtering out harmful air-borne microbes and substances.

These face masks before development is made sure that it prevents the invasion of COVID-variants and also protects people from influenza, measles, mumps, sneezing etc. So, the decision on the use of raw materials and

Inside look of the manufacturing angle

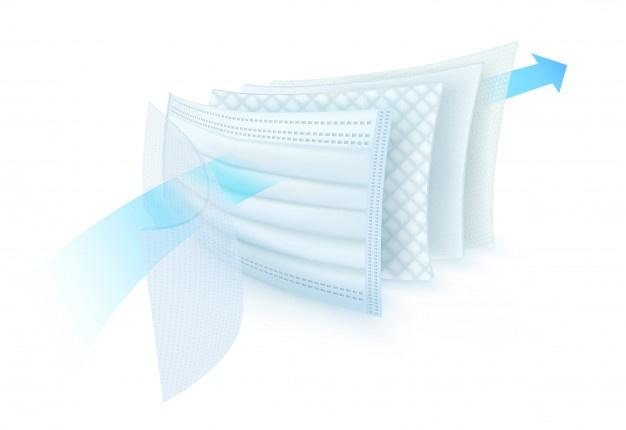

These companies who are into making OEM face masks make sure that they use three layers to make masks that are more efficient and are manufactured at less cost. The custom-made “mask maker” automatically sandwiches the filter material and metal nose piece between an inner and outer layer of fabric. It then folds the pleats, welds the layers together, and cuts each mask according to the designer’s precision and measurements.

Employees then cut the ear loops from elastic straps and attach them to the mask using sonic welders. These sonic welders use ultra-fast vibrations to “melt” the two materials together, without using heat. These earloops are scrutinized to ensure size and secure attachment to the mask.

These masks once designed are loaded into a sterilization cabinet to sanitize the mask for at least 20mins.

Performance standards

Specific requirements by the classification are cited in the referenced performance standards. And some of the evaluation standards are:

- Marking and labelling

- Particulate Filtration Efficiency (PFE)

- Bacterial Filtration Efficiency (BFE)

- Differential pressure (breathability)

- Blood penetration resistance

- Flammability

- Microbial cleanliness

- Biocompatibility

Certifications

- NIOSH: A N95has to go through NIOSH certification so that the face mask manufactured has an efficiency of 95% particulate filtration, working for the welfare of a common man.

- FDA OUK: The OUK classification is newly made for the Respokecare N95 masks available from N95 mask manufacturers that only block airborne particles but also an antimicrobial treatment that renders 99.9% of viruses inactive within minutes of contact.

Once the face masks are developed using research data, manufactured through suitable machinery, sanitized, tested following govt. authorised certifications, these masks are shipped to you. And you can sell these ready-to-ship masks under your brand name without any legal issues.