In the realm of infrastructure and construction, the importance of stable and durable foundations cannot be overstated. As the demands for robust and sustainable building materials continue to rise, polyester geogrids have emerged as a versatile solution for enhancing soil stability and reinforcing structures. Singhal Industries Pvt Ltd, a pioneering packaging company in India, has expanded its portfolio to include PP Geogrid Manufacturer in India, contributing to the construction industry's evolution towards safer, more resilient infrastructure. In this article, we explore the benefits, applications, and innovations surrounding polyester geogrids, while shedding light on Singhal Industries' commitment to excellence and customer satisfaction.

In the realm of infrastructure and construction, the importance of stable and durable foundations cannot be overstated. As the demands for robust and sustainable building materials continue to rise, polyester geogrids have emerged as a versatile solution for enhancing soil stability and reinforcing structures. Singhal Industries Pvt Ltd, a pioneering packaging company in India, has expanded its portfolio to include PP Geogrid Manufacturer in India, contributing to the construction industry's evolution towards safer, more resilient infrastructure. In this article, we explore the benefits, applications, and innovations surrounding polyester geogrids, while shedding light on Singhal Industries' commitment to excellence and customer satisfaction.

Understanding Polyester Geogrids

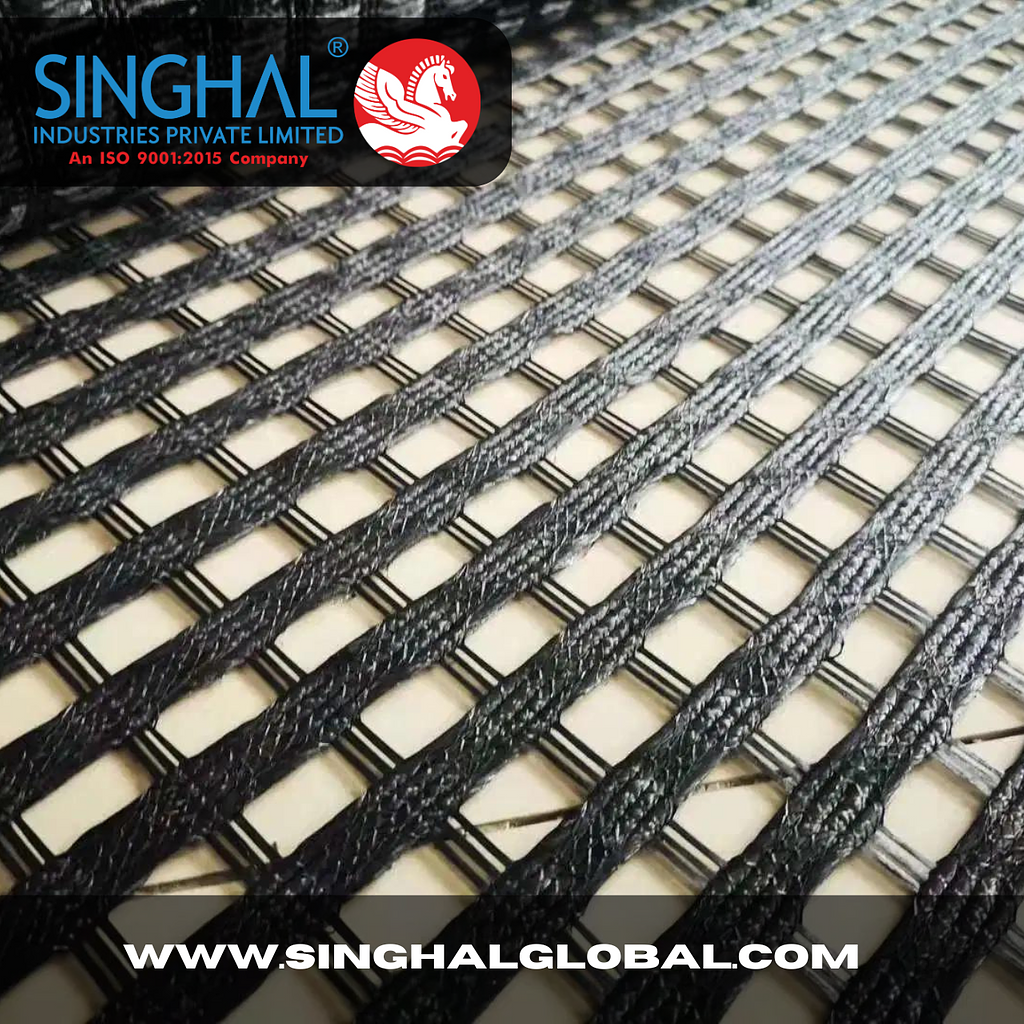

Introduction to Polyester Geogrids: Polyester geogrids are synthetic materials composed of high-tenacity polyester yarns, which are knitted or woven into a grid-like structure. These grids are then coated with a protective layer to enhance durability and resistance to environmental factors such as UV radiation, moisture, and chemical exposure.

Functionality of Polyester Geogrids: Polyester geogrids serve as reinforcement materials in civil engineering and construction projects, where they are used to stabilize soil, control erosion, and improve the load-bearing capacity of foundations. By distributing stress and reducing lateral movement, geogrids help prevent soil settlement and structural failure, leading to safer and more sustainable construction practices.

Benefits of Polyester Geogrids

-

Enhanced Stability: Polyester geogrids provide structural reinforcement, increasing the stability and load-bearing capacity of soil and aggregate materials. This results in stronger foundations and reduced risk of settlement or failure.

-

Improved Durability: With their high-tensile strength and resistance to environmental degradation, PP Geogrid Supplier in Ahmedabad offer long-term durability, ensuring reliable performance even in harsh climates or challenging terrain.

-

Versatility: Polyester geogrids are suitable for a wide range of applications, including road construction, slope stabilization, retaining walls, embankments, and landfill engineering. Their flexibility and adaptability make them indispensable in various civil engineering projects.

-

Cost-Effectiveness: By minimizing the need for extensive excavation and heavy machinery, polyester geogrids help reduce construction time and costs. Their lightweight and easy installation further contribute to overall project efficiency.

-

Environmental Sustainability: Polyester geogrids support sustainable construction practices by promoting soil conservation, reducing material wastage, and minimizing the environmental footprint of infrastructure projects.

Applications of Polyester Geogrids

-

Road Construction: Polyester geogrids are used in road pavements to improve subgrade stability, prevent rutting and cracking, and extend the service life of the pavement.

-

Retaining Walls: Geogrid-reinforced retaining walls provide structural support for soil masses, preventing erosion, landslides, and slope failure.

-

Landfill Engineering: Geogrids are employed in landfill liners and caps to enhance containment systems, prevent soil erosion, and mitigate environmental contamination.

-

Railway Infrastructure: Geogrids are utilized in railway embankments and trackbeds to distribute loads, reduce settlement, and improve track stability.

Singhal Industries: Setting the Standard in Polyester Geogrids

Advanced Manufacturing Facilities: Singhal Industries operates state-of-the-art manufacturing facilities equipped with modern machinery and technology for producing premium-quality polyester geogrids with precise specifications.

Stringent Quality Control: With a focus on quality assurance, Singhal Industries implements stringent testing protocols and quality control measures to ensure that every geogrid meets international standards and customer expectations.

Customization Options: Singhal Industries offers customization options for PP Geogrid Manufacturer in Gujarat, including width, length, strength, and coating properties, to address the specific requirements of different applications and projects.

Technical Support: Singhal Industries provides comprehensive technical support and expertise to customers, offering assistance with product selection, installation guidelines, and project specifications to optimize performance and efficiency.

Conclusion

Polyester geogrids represent a significant advancement in civil engineering and construction, offering a reliable and cost-effective solution for enhancing soil stability and reinforcing structures. Singhal Industries' commitment to innovation, quality, and customer satisfaction has positioned it as a leading provider of polyester geogrids in India. With its comprehensive range of products, technical expertise, and dedication to excellence, Singhal Industries continues to drive progress in the construction industry, contributing to the development of safer, more resilient infrastructure for communities worldwide.

Frequently Asked Questions (FAQs)

Q1: What is the maximum tensile strength available for Singhal Industries' polyester geogrids?

Singhal Industries offers polyester geogrids with a wide range of tensile strengths, ranging from standard grades to high-performance options tailored to meet specific project requirements.

Q2: Are Singhal Industries' polyester geogrids suitable for use in coastal or marine environments?

Yes, Singhal Industries' polyester geogrids are designed to withstand exposure to saltwater, UV radiation, and other environmental factors commonly encountered in coastal or marine applications.

Q3: Can polyester geogrids be installed in conjunction with other geosynthetic materials?

Yes, polyester geogrids can be used in combination with geotextiles, geomembranes, and other geosynthetic materials to create multi-layered composite systems that address various soil stabilization and reinforcement needs.