Rigid Plastic Packaging is usually known as rigid in the industry, and are a classification of plastics usually made from HDPE and PP rigid. The goods are plastic containers which are opened and the top and have separate closing lids or the covers. They are usually nestable food storages which could be recycled. Few known ridig plastic packaging types are butter tubs, curd cups and several containers for things such as dips, hummus and spreads. Rigid mimic a very vital role in the screens of the grocery shops and super markets. Huge and big rigid containers are mostly utilized in bakery, pharmacies departments, seafood, deli and retailers to transport the wide range of foods, goods and medicaments on which people depend upon in the daily lives.

Some of the manufacturers collaborated with the Association of Plastic Recyclers to increase the recycling of rigid plastic packaging in groceries found on the back of the counter in a series in supermarkets, give valuable profitable feedstock to plastic containers and assist to meet and fulfil the need of feedstock. The grocery rigid plastic packaging recycling program gives the grocery departments with the most essential rigid plastic data as they are green operations in both the ways environmentally as well as financially. Recycling the rigid is the 3rd compound of an equal and balanced recycling program groceriesery, recovering the cardboard, rigid plastic and plastic film. There are several benefits and advantages of rigid plastic packaging.

Several rigid plastic packaging are very advantageous due to its versatile nature and these containers can be made in any of the shapes and designs, rigid plastic packaging is very protective and is also very affordable and is also very easy to recycle. The most advantageous thing in ridig plastic packaging is its protection. Let it be a clamshell food container or the mobile packaging rigid plastic packaging guarantees that the goods would be transported and delivered the way one wishes it to be. This thermoform plastic is resistant to the components, keeping outdoor debris from the item so one has nothing to worry regarding the product being destroyed. Furthermore, it is gives safety for the items, it being hard and plastic is more durable. Anyways, there is always a substrate for people even if there is no plastic packaging. From the durable and light-weight plastics to very huge and heavy duty.

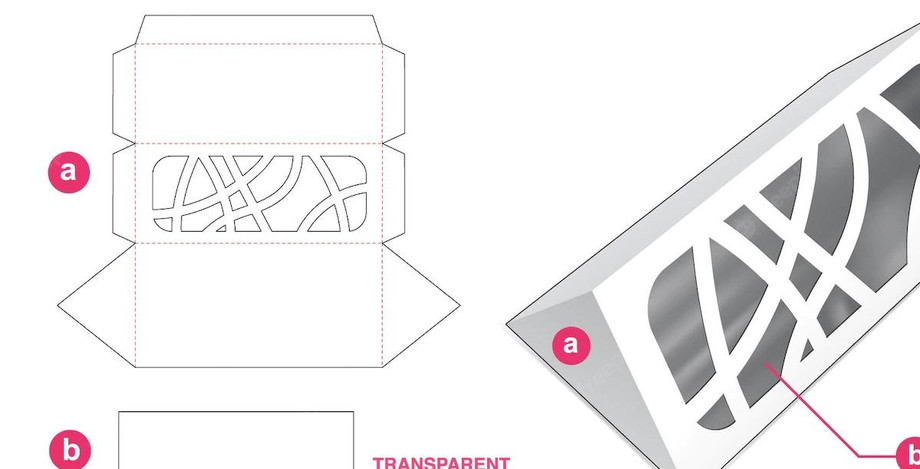

A talented producer of the packaging can assist in determining the substance that would be very budget-friendly when fit into the items requirement. Because of the thermoforming molds, rigid plastics can be made of different shapes and molds. Where usual options comprise stock packaging such as takeout containers, rigid plastic also be given uneven shapes as per the settings apart from the product. It also has a vast recycling ability. Recycling was earlier restricted to only some type of products and some forms if plastic. Currently rigid plastics are also being allowed for the recycling methods. The only disadvantage that a rigid plastic packaging possess is rising transportation of goods as the increase in capacity causes huge budget across the distribution chain.