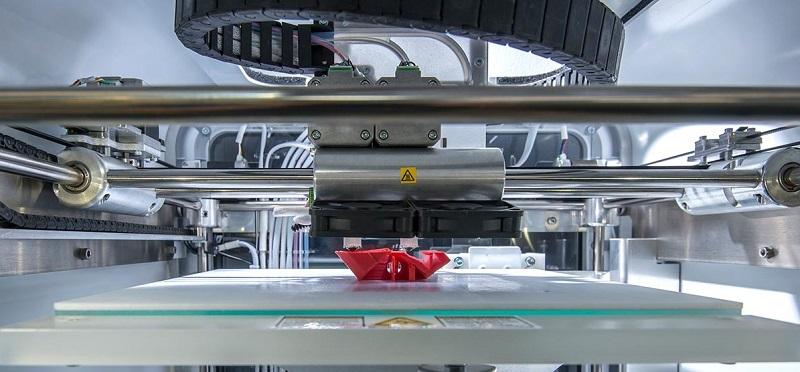

The continuing evolution of 3D printing technology is driving growth and efficiency throughout the manufacturing industry. Whether in designing or prototyping, 3D printing in India is becoming more and more affordable, thereby enabling manufacturers to benefit in their processes of low-volume as well as mass production. In this article, we discuss some of the major advantages of 3D printing technology in the manufacturing industry.

Cost-effective

Manufacturers are increasingly opting for 3D printing solutions in their production processes. This is, to a great extent, driven by the low costs of using additive manufacturing. Moreover, 3D print technologies are more accessible than many conventional manufacturing techniques.

Labour costs, for example, can be drastically reduced with online 3D printing, whereby only a couple of steps have to be manually operated, while the rest is automated. This also helps to keep human errors at a minimum.

Faster Transition from Concept to Product

Enlist the expertise of 3D printing services to expedite the process of product development. In fact, additive manufacturing technologies make it possible for 3D designs to be conceived and printed on the same day, albeit for small production runs for the manufacturing of spare parts

Lesser Risks and Greater Freedom in Designing

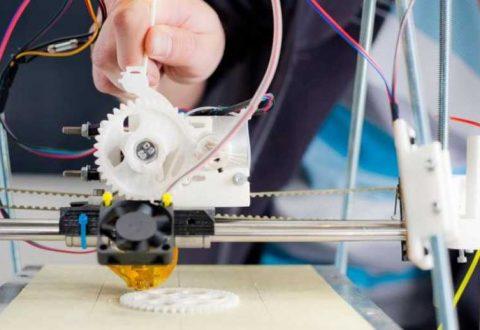

Rapid prototyping has enabled design engineers to take a greater amount of risks without worrying about the financial fallout of potential failures. With 3D prototyping, it is easier to redesign and make alterations, which also boosts the overall confidence of designers.

3D printing has brought about infinite design possibilities for the manufacturing process. Imagine how much liberty you can give your designers to play around and test complex geometries. It is now much easier to transform complicated designs into actual parts and end-products.

Less Inventory

Inventory and warehousing is a major source of expenses for manufacturing companies. Storage of traditionally manufactured parts costs a significant amount of money. In contrast, with 3D printing enabling on-demand production in small batches, produce and sell off parts and products as needed, thereby doing away with warehousing altogether!

Reduce Manufacturing Wastes and Go Green

Traditionally, manufacturing processes produce a lot of material wastes. 3D printing uses resources a lot more efficiently, using only that much of a particular material (and there is an ever-growing inventory of 3D print materials) as the printing machine requires. This makes additive manufacturing a sustainable form of manufacturing while being environmentally friendly. Manufacturers are attracted to this aspect of the technology as it helps them meet environmental regulations laid down by the government.

In fact, 3D printing in Pune is also helping manufacturing businesses create goodwill among their customers as with their message of recycling. For example, there are certain industrial 3D printers that make use of shredded plastics as their feedstock. This makes for truly green product alternatives.