Commonly times, a welding assessor may be working on sky-rises and also other structures that are high off the ground, which indicates that an examiner should not have a fear of heights. A welding assessor has a clear understanding of welding techniques, and also apart from examining, have to be able to weld and also evaluate steel samples for suitable welding strategies and processes. ASME Inspection.

Appropriate interaction is even more crucial offered the security as well as severity of the concerns a welding assessor is in charge of. Most of all, a welding examiner should have accreditation to perform examinations in a specific field. Not just does this assistance make sure that the welder is existing on proper treatments and policies, however it is something most, if not all, employers need - Weld Inspection.

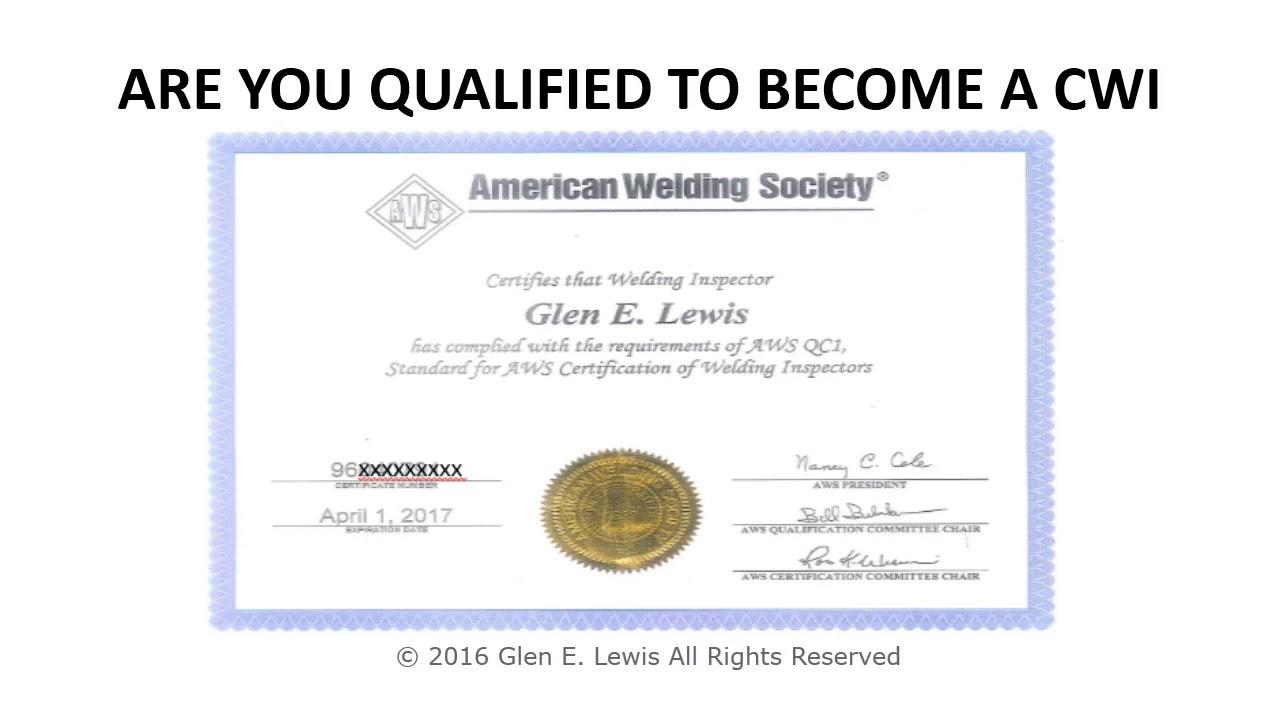

Usually, welding experience counts as one of the most essential ability when obtaining certified for an assessment work. Depending on the qualification he receives, a welding assessor may operate in several different locations - ASME Inspection. One of the companies that supplies accreditation in the USA is the American Welding Society, which certifies welders to execute evaluations on frameworks, such as structures and dams.

Each organization has its very own codes the examiner needs to follow by, which are called the Welding Treatment Specs (WPS).

Not known Incorrect Statements About Aws Cwi Certification

Elderly Staff Engineer, National Board This short article was originally published in the Autumn 2009 National Board PUBLICATION as the very first of a two-part collection. Please see Fundamental Weld Inspection - Part 2 for the conclusion of this short article. Keep in mind: The objective of this post is to provide inspectors with a general expertise of weld assessment.

Weld inspection starts long before the initial welding arc is struck. The assessor needs to evaluate the job bundle to come to be familiar with the: welding procedures to be made use of; materials and any kind of special properties; joint setups and also preparation; welding procedure requirements to be made use of and also any limitations; certifications of welders to be utilized as well as any constraints; warm treatment (pre-heat or postweld), if any; nondestructive assessment (NDE), if any; and also details ASME Code or NBIC requirements (for instance, Area VIII, Div.

While not important, the assessor must discover to check out typical weld signs such as the AWS symbols. At least, the inspector ought to constantly bring a reference overview to analyze weld signs. Having actually assessed all this information in breakthrough, the assessor will certainly be prepared to acknowledge any kind of troubles as they establish rather than after-the-fact.

The manufacturer or repair organization (certification owner) has suggested on the job attracting that a weld joint is to be prepared with a 60-degree bevel as well as root space of 1/16 inch. ASME Inspection. Unless the bevels are milled on precision machinery, it is doubtful they will attain a precise 60-degree bevel as suggested.

The Ultimate Guide To Pipe Welding Inspector

Offering a plus or minus tolerance will make the welder's task much less complicated. The assessor can utilize scraps of weld filler cord or poles as a scale to quickly identify root gaps that are beyond the tolerance variety.

A 1/8-inch cable needs to display no side-to-side activity throughout the void. Real life scenarios are hardly ever this practical, however the examiner can create a sense of "too tight" or "too loose" with experience. The certificate owner has designed a basic nozzle to be welded to a level head (Fig.

The nozzle axis is 90 to the level head, and also the accessory weld includes a 3/8-inch fillet weld. The assessor can quickly determine the fillet weld to make sure compliance.

This example ends up being also much more important if the nozzle is set up at an angle besides 90 (Fig. 3). Utilizing the exact same nozzle attachment instance as defined over, let's look at the weld joint prep work - Weld Inspection. The certificate owner has actually specified a 45-degree bevel around the circumference of the hole in the flat head and the vessel shell.

Some Ideas on Asme Inspector You Should Know

4). The curved shell will certainly present more of a challenge. The inspector will certainly need to determine if the certification holder is referencing the bevel from the vertical axis of the nozzle (Fig. 5) or from the variable reference airplane of the rounded covering (Fig. 6). When bevels are prepared with a reducing torch and ended up with a grinder, it is very tough to preserve a specific angle.

Even acquiring a flawlessly circular hole when utilizing a torch and also grinder is hard (Certified Welding Inspector). Components are readily available which connect to the lantern to help in cutting round holes and also bevels, however the arrangement is occasionally inconvenient. A certification owner is preparing to bond numerous hundred circumferential joints in power boiler tubes.

How does the examiner guarantee conformity with the code? Assessors are trained to think just what their eyes tell them; yet when the inspector can not see the inner surface of the tube, it becomes hard to accept that situation. This is when the inspector must take what some would certainly call a "leap of faith." If television ends are correctly prepared (beveled) and a certified welder is using a certified welding treatment, the odds are excellent that the welds will certainly be full infiltration.

One "warning" to a prospective trouble would certainly be if the examiner observes that the tube ends have not been beveled. The assessor needs to promptly ask the certificate owner about this circumstance - Pipe welding inspector. It could be as simple as the certificate owner having actually simply not carried out that action in the procedure yet, or it might be as negative as his or her having attempted to conserve time and also cash by not beveling completions.

Get This Report on Asme Inspector

The welder would need to begin with a big root space and afterwards be really mindful not to "press via" excess filler metal to create weld build-up on the within television.