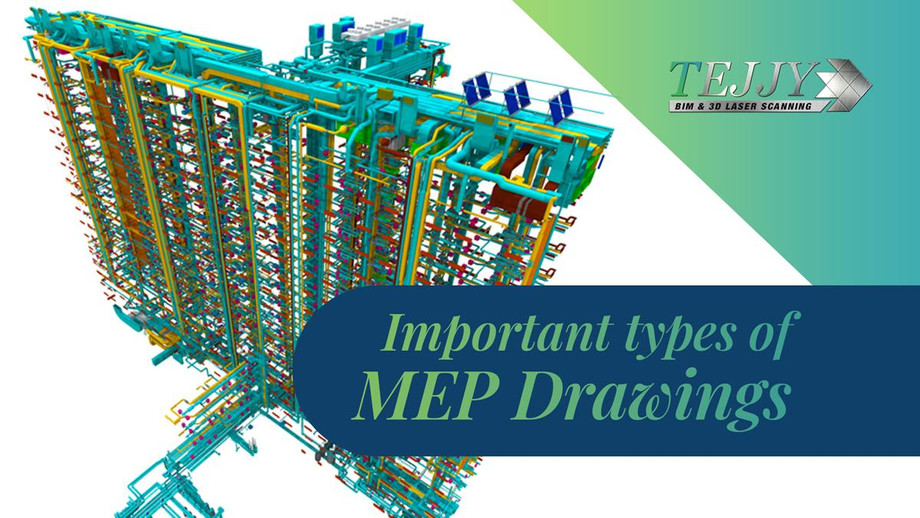

With the use of MEP drawings, the Mechanical, Plumbing, and Electrical systems of a building can be built, installed, and maintained. The Mechanical discipline focuses on the Heating, Ventilation, and Air-Conditioning (HVAC) systems, the Electrical component of this discipline refers to the power supply, and the Plumbing element of this discipline focuses on the water supply and wastewater drainage. For the most part, Revit MEP, AutoCAD, and, Autodesk Inventor are the software that is utilized by MEP firms in the process of generating MEP designs after clash detection and MEP coordination.

Let us look at the names of different types of MEP drawings:

Detailed shop drawings

Shop drawings are necessary for the prefabrication and installation of Mechanical/HVAC, Electrical, Plumbing, and Fire protection components such as ducting, air-handling units, specialized pipe connections, etc. MEP shop drawings outline the steps to be taken in creating and installing the building's infrastructure. These blueprints guarantee that any off-site-manufactured part will fit into its intended installation without any problems. MEP fabrication shop drawings adhere to the required standards codes.

Penetration drawings

Drawings of penetrants, such as Mechanical, Electrical, and Plumbing services that penetrate through the floor or wall of a building, are referred to as penetration drawings. The size of this opening needs to be precise and sufficient in order to allow various services to pass through it without causing any collisions. The accuracy with which these components are located can be improved with the use of penetrating sketches. This is made much simpler because of the accurate dimensions that are provided in the drawings.

Pipe spool drawings

An assembly of pipes is referred to as a spool, and it is concerned with the components that can be pre-fabricated in the workshop for the purpose of installation, and then sent to the site thereafter to be assembled there. The plumbers can figure out what needs to be done with the help of these pipe spool drawings, which serve as a reference. The spools are connected at various intersections throughout the entirety of any construction that is concerned.

The drawings are accurately detailed so that they can effectively communicate all of the information that the fabricators require in order to precisely produce and install the spool. When all of the information for all of the elements that will be welded together into a single drawing is collected, then a spool drawing may be created.

Coordination drawings

The coordination MEP drawings provide assistance in locating clashes that are brought on by the interaction of the mechanical, electrical, and plumbing systems, and also with other services including architectural and structural. For instance, the team can determine well in advance of the installation process whether or not there is a collision between a water pipe and a duct by consulting these records. This provides the team with a plan of action that is clearer and helps to restrict any potential physical conflicts in the equipment layouts, electrical piping, drainage channels, or duct route configurations.

As built drawings

After the construction of the building, the MEP As-built drawings are created to understand how the MEP services are installed. This helps to understand how these services are planned, and how they are finally executed. These drawings are used by clients and facility managers for the operations and maintenance of the buildings. MEP As-built drawings can be created for existing buildings with the help of 3D laser scanning and Scan to BIM technology.

Conclusion

When it comes to the planning and construction of a building's Mechanical, Electrical, and Plumbing (MEP) systems, MEP drawings are an extremely important component. These drawings offer a full overview of the MEP services of the building, enabling effective and efficient coordination among these services.

When it comes to ensuring the success of a building construction project, having MEP plans that are both accurate and up-to-date is absolutely necessary. The advantages of possessing a set of MEP shop drawings are limitless in the AEC industry. It helps to make the entire building construction process go much more smoothly and contributes to the conservation of resources by reducing or eliminating the need for restructuring or adjustments.