Fiberglass grating, also known as FRP grating, has become a popular choice for various industrial, commercial, and residential applications due to its unique combination of strength, durability, and lightweight properties. This article delves into the key aspects of fiberglass grating, exploring its characteristics, benefits, types, and common uses.

What is Fiberglass Grating?

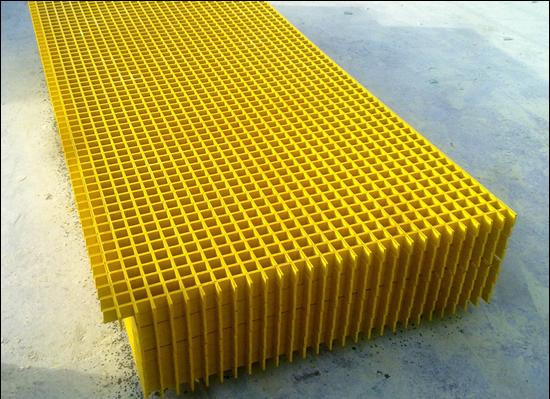

Fiberglass grating is a composite material consisting of woven fiberglass strands embedded in a thermosetting resin matrix. This process creates a rigid, lightweight, and corrosion-resistant grid structure with superior strength-to-weight ratio compared to traditional materials like steel.

Key Benefits of Fiberglass Grating

Fiberglass grating offers several advantages over other materials, making it suitable for various demanding environments:

-

- Corrosion Resistant: Fiberglass is inherently resistant to rust, chemicals, and saltwater, making it ideal for marine environments, chemical plants, and wastewater treatment facilities.

-

- Lightweight: Compared to steel, fiberglass grating weighs significantly less, simplifying installation and reducing structural load requirements.

-

- High Strength: Despite its lightweight nature, fiberglass grating offers excellent strength and load-bearing capacity, suitable for walkways, platforms, and mezzanines.

-

- Slip-Resistant: Most fiberglass gratings have a gritted surface for enhanced traction, improving safety in wet or oily environments.

-

- Low Maintenance: Unlike steel, fiberglass grating requires minimal maintenance, eliminating the need for painting or regular rust prevention measures.

-

- Fire Retardant: Fiberglass grating can be formulated with fire-retardant resins, meeting specific fire safety requirements in various applications.

-

- Non-Conductive: Fiberglass acts as a natural insulator, making it safe for use around electrical equipment and preventing accidental shocks.

Types of Fiberglass Grating

There are two main types of fiberglass grating, each with distinct properties:

-

- Molded Grating: Created by pressing a resin-impregnated fiberglass mat into a mold, offering high chemical resistance and strength.

-

- Pultruded Grating: Manufactured by pulling continuous fiberglass strands through a resin bath, resulting in consistent strength and dimensional stability.

Additionally, variations exist within each type based on resin system, mesh size, and surface texture, catering to specific application needs.

Common Applications of Fiberglass Grating

The versatility of fiberglass grating makes it suitable for a wide range of industries and applications, including:

-

- Industrial: Walkways, platforms, mezzanines, trench covers, drainage systems, chemical plants, oil and gas facilities, power plants, food processing plants.

-

- Commercial: Stair treads, catwalks, rooftops, pool decks, marine docks, water treatment plants, parking structures.

-

- Residential: Decking, balconies, porches, walkways, hot tub surrounds, fence panels.

Conclusion

Fiberglass grating is a valuable material for various applications due to its unique blend of strength, durability, corrosion resistance, and lightweight properties. Understanding its benefits, types, and diverse applications empowers individuals to make informed decisions when selecting materials for their specific needs.