Various applications of flexible objects require innovative and versatile materials, and 4D printing is a promising alternative. The method creates a meta-material structure through the congruent printing of various materials. Researchers are examining ways to expand the meta-material structure to allow the object to change its structure in response to varying external conditions.

This is a rapidly evolving technology, and its application is likely to change the world of manufacturing.

The technology is also gaining popularity as a tool for creating biomaterials and other products. The benefits of 4D printing extend beyond the biomedical realm. Printed solar panels and tissue engineering are two examples of potential applications. Other industrial applications include coatings for airplanes and spacecraft that adapt to the climate and humidity. For the art world, 4D printing can help create self-repairing parts for vehicles and aerospace, and the military and defense sector can take advantage of its ability to customize objects in a wide range of materials.

The technology can even be used in medical applications, including 3D printed organs. The latest innovations in 4D printing include smart materials, low-cost printers, and flexible materials. Currently, 4D printers lack the capacity to print complex objects, which can interfere with the ability of medical devices. Moreover, the process is slow, which limits its long-term reliability. However, as more advanced machines are developed, more diverse applications of this technique can be developed.

While 4D printing is still a novelty for many people, its use is becoming a necessity for the aerospace industry. With the world's population increasing, cities will be expanding to the point where they will be called megacities. These cities are growing at a rapid pace, and the number of these cities will increase to 41 in the next decade. As a result, 4D printing will create a huge demand for materials, manufacturing, and distribution.

In addition to the automotive industry, 4D printing is reshaping the manufacturing industry. It can produce high-quality, durable materials for products. It can also create custom-made parts for a product. The technology is also capable of self-replicating products and other products. Currently, it is a viable option for manufacturers that can customize a product to fit the customer's needs. This can reduce shipping costs, and improve customer service.

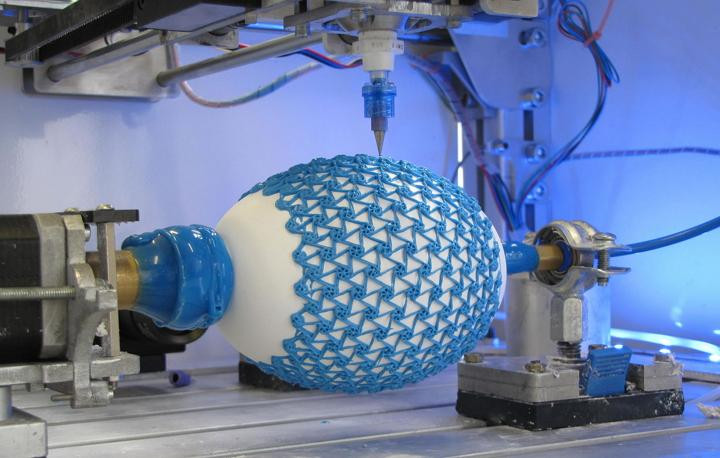

The advantages of 4D printing are vast, and they will continue to attract increasing attention in the future. So, while there is still a long road ahead, the future is bright for this emerging technology. Unlike 3D printing, 4D printing uses the knowledge of material properties to create complex objects. Using advanced software, engineers can design objects with variations in their materials. A digital CAD design is then 3D-printed in a composite or single material. The behavior of the finished product is dictated by a preprogrammed geometric code. For instance, it can produce components that fold or unfold, or that respond to a stimulus.

The concept of 4D printing is an evolution of 3D printing. The concept of 3D printing has been used for centuries to produce complex objects. Current technologies allow engineers to design objects with varying material structures and behavior. This technology also enables them to create composite materials that are more functional than their counterparts. They can also produce objects that disintegrate or fold, depending on their physical properties. The technology of 4D printing is now a viable alternative to traditional plastic additive manufacturing.