What is Servo Motor?

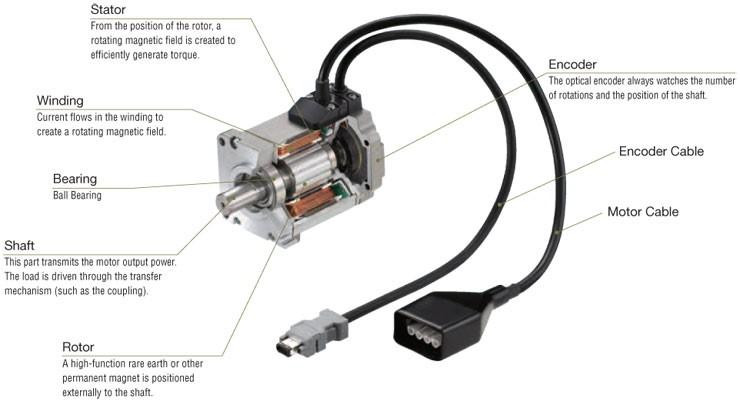

There are different types of electric motors available in the market. The choice of these motors can be based on the operation and voltage of the applications. Motor applications sometimes require motor rotation to stop at a certain angle with a minimum backlash rate for the typical output used by servo motors in electronic applications. A servo motor is basically a DC motor that connects the driver and encoder to become a servo motor. Servo motor can give output up to 3000 rpm. With the help of a driver you can control it. The encoder is connected to the driver which sends feedback and signals to the drivers on how to operate. The driver acts according to the signal passed through the encoder. The components of servo motor are mentioned in the picture below.

WHAT IS A NEED OF SERVO GEARBOX?

The main reason for using servo motor in any electronic application is to control its speed, in applications where the rotation of the motor must be stopped at a certain angle. When the servo motor stops at a certain angle the gearbox must also stop at the same point so that the gearbox must come with a very low backlash rate. Servo gearboxes provide multiplication, speed reduction and inertia matching for motorized systems. When a gearbox is attached to a servo motor, the rotating speed given by the motor can be reduced by the number of gear ratios which allows the application to make better use of the speed torque feature of the servo motor. Servo motors require gearboxes that can provide high torque with low added inertia, high accuracy. The servo gearbox takes the input of the motor and transmits the precisely calculated output to the application, which helps the application to give accurate results. The most important advantage of using a gearbox in a servo system is the effect it has on the inertia of the load. The load inertia, which is reflected on the motor, is reduced by the square of the gear ratio. Therefore, even a relatively small gear reduction can have a significant effect on the inertia ratio.

Servo Gearboxes mainly known as precision gearing series. Servos are an electromagnetic device that converts electricity into precise controlled motion by use of negative feedback systems. Hence this system mainly used into the precise operations such as Laser printing, water jet cutting, semiconductors, pharmaceutical industries.

SMD Gearbox- Servo Gearbox Manufacturer

Seimitsu Motion Drives is a gearbox solution provider. It is a Taiwan based organization with overseas office in India. SMD Gearbox has a long list of satisfied customers. All SMD gearboxes can be used for servo motors. SMD's gearbox comes with attractive features like minimum backlash rate. SMD has a wide range of different ratio gearboxes to integrate with the specifications of your application. All gearboxes operate at a backlash rate of less than 1 arc-min which helps the servo motor to produce accurate output. The minimum backlash is that the gearbox will stop at the exact angle at which the application is to be stopped. Nowadays almost all applications use servo motor due to its efficiency and hence the market for servo gearbox is growing day by day. SMD gearboxes are as follows:

- Planetary or Inline gearbox with flange End

- Planetary or Inline gearbox with shaft End

- Right angle Gearbox

- Hollow Rotary Gearbox

- Harmonic Gearbox with solid shaft

- Harmonic Gearbox with Hollow shaft

- Cycloidal Gearbox

SMD Gearbox is committed to developing its business through different growth strategies: expanding the geographical range of its operations through full scale globalization, purposefully expanding its domains through the development of new business areas, and utilizing technology. To know more how SMD gearbox can help you in your system automation visit our website www.smdgearbox.com or you can mail us for personal assistance on sales@smdgearbox.com.