The activities in the industry are very important for the emergence of goods and these loads are destined for retail trades of different sizes. Diversity is a condition that can generate interesting and prosperous results for companies.

The secret to success in the industry is related to creating a good plan. A document in which professionals dedicate time to decide the products to be manufactured, machinery needed, materials to work with and other points that make a difference in the results.

Industrial production methods

In industry, there are many different ways of producing goods. Machining is a production method that consists of transforming a solid block of raw material into a part or mold.

Machining companies use a series of machines and tools with adequate power to perform cuts, bends, finishing, repairs and designs that allow the emergence of molds and parts.

The equipment, tools and machines that companies usually invest to meet customer demands are the machining center, three-dimensional machine, lathe, milling machine, horizontal boring machine, flat and cylindrical grinding machine, cutting machine and some CNC equipment (Computer Numerical Control ).

These machines perform operations according to programming and handling. The processes carried out consist of threading, honing, planning, broaching, milling, EDM, drilling, sawing, sharpening, boring, grinding, trepanning and turning.

One way to achieve excellent results in machining is by investing in the implementation of industrial automation systems, which consist of using technology in favor of productivity.

The importance of automation in industry

Industrial automation consists of the use of machines and electromechanical equipment and software, tools used to automate industrial processes.

In general, the advantages of automation are related to aspects such as:

- Increased productivity;

- Constant monitoring;

- Decreased production time;

- Reduction of installation costs;

- Low human error rate;

- Safety on the shop floor;

- Quality optimization;

- Greater production volume and flexibility;

- Competitive advantage;

- Precision and possibility of reproducibility.

The machinery used in automation processes can be diverse and consists of parts such as PLC (Programmable Logic Control), computers, CNC (Computer Numerical Control), microcontrollers, servo motor, DCS (Distributed Digital Control System), robots, transducers, sensors, actuators and control systems.

A servo motor , for example, is an electromechanical machine that presents movements proportional to the commands, helping in the precision of the processes.

The benefits of this equipment are:

- Low noise and vibration rate;

- High driving force;

- High precision in controls;

- high torques.

A very useful material to add comfort to operators is the keyboard membrane, a material used in computers enabling the control of parts. The membrane has only the contours and symbols printed on the surface and can be flexible or flat. Additionally, it may have little or no tactile feedback felt during use.

This keyboard model is excellent value for money, a factor that allows it to be purchased for use on multiple computers.

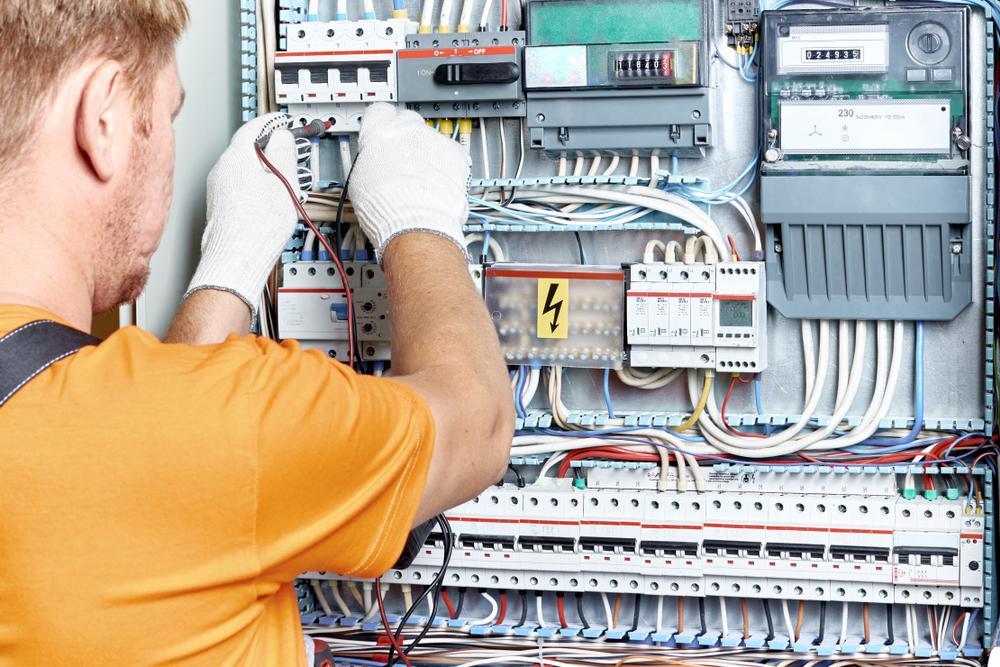

Electrical installations

The assembly of panels is a job that requires specialized labor, due to the dangerous level of electricity.

The panel has the function of concentrating, controlling and distributing the different electronic devices of the companies.

The components that are inside are: circuit breakers, relays, contactors, transformers, power supply, signals, grounding terminals, switches and other components that help in the functioning of the energy.

The companies that carry out the assembly can take care of the part related to industrial electrical maintenance , a process that consists of analyzing the state of conservation of the materials, managing the electricity supply that guarantees full conditions of use, helping to avoid distribution failures.

Electrical maintenance involves several areas of the industry, such as lighting systems, electrical, hydraulic, pneumatic machines and surge protection.

So, researching the cost of service of various maintenance companies is a way to get excellent value for money and quality work.