Currently put the second flooring panel and as well as so on, till the installment of the very first row of flooring panels is completed. After the third row has been laid, check again if the flooring is level (Epoxy flooring).

After the floor panels have been marked out. If a hand saw is utilized, make sure the design side is dealing with upwards.

Lay the very first row of panels by gluing each subsequent panel on the short side. In the second row, begin with the continuing to be component of the first This component, nonetheless, should be at least 40cm in size so regarding guarantee that the floor has optimum security as well as likewise to guarantee minimum waste of material.

Do not use extreme quantities of adhesive. To tighten up, utilize the covering block of the laying collection.

Concrete Polishing Fundamentals Explained

While fitting the last row of the floor panels, lay the flooring panels with the attractive side down with the groove versus the wall surface. Currently make the needed markings as well as cut with the Additionally remember the prescribed expansion joint of 15mm which the floor ought to be totally free all over.

That risks drawing splinters off the sides or deteriorating them so they may splinter at a later point. Make sure to make use of a touching block that is large sufficient. The tapping block ought to be more than 300mm If the touching block is also tiny, the edges of the floor planks could be damaged, and also over time, the edges may splinter.

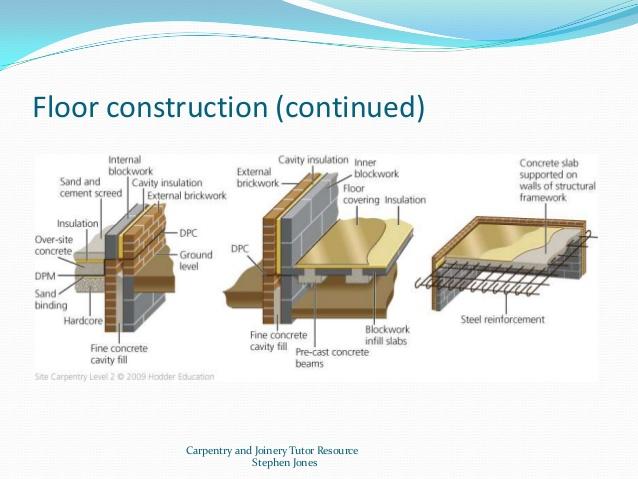

Exactly how to Prepare Your Subfloor for Different Flooring Setup, The installment technique of floor covering varies depending on the subfloor as well as the floor covering product of your choice. To guarantee your flooring is durable and looks gorgeous, the installment needs to be done perfectly. The top quality as well as kind of the subfloor impact the installment procedure, making the preparation of the subfloor an essential as well as indispensable job.

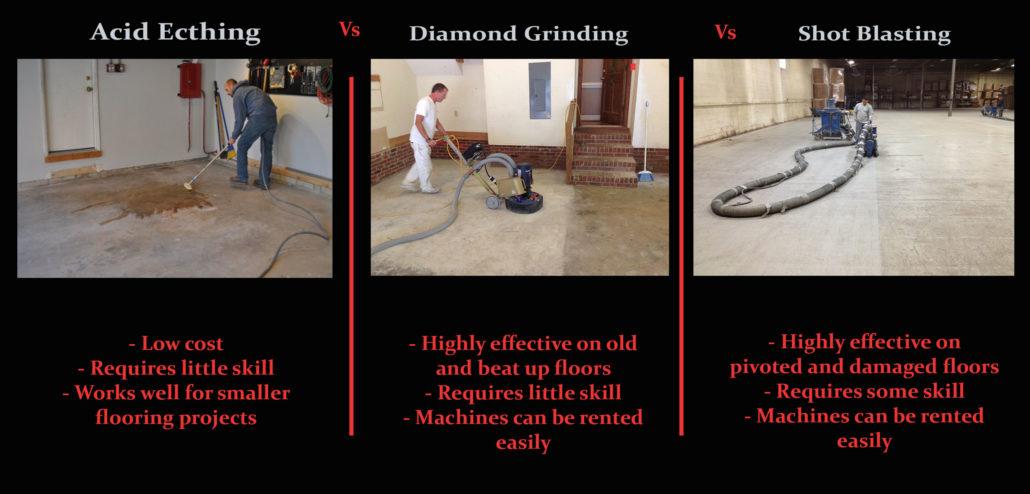

If you have a concrete subfloor, a moisture obstacle is necessary when you are mounting wood or laminate floor covering. Clean the glue and also dirt deposit of the old floor covering, and extensively vacuum the location. This is an essential action if you are making use of the gluing down technique of flooring installment as the flooring product will straight be laid on the subfloor.

The Only Guide for Residential Polished Concrete Floors

The flaws of your subfloor can conveniently show via the carpeting considering that it is a soft and also adaptable flooring product. Yet on the intense side, carpeting setup can be done on a variety of subfloors consisting of linoleum floor tiles. Below are a few points you must look after before a: If you had carpet flooring in the past, the old carpet staples need to be eliminated to guarantee the floor is as smooth as feasible for perfect installment of the new carpeting. Residential polished concrete floors.

Utilize an appropriate underlayment on the subfloor to avoid any damage from underneath. You can utilize a primer to secure the wooden subfloor if it has any kind of small wetness damages to stop it from influencing your new floor covering.

The complying with are certain things that you can do to lessen the opportunity of these troubles happening. If you have a concrete subfloor, also out the surface area by repairing small spots as well as replacing the areas of the concrete piece if there are huge cracks. Using concrete filler to smooth out cracked locations in the concrete subfloor one more selection you have if you do not wish to replace the slabs (Epoxy flooring).

The surface of the plywood subfloor should be sanded completely to also out the surface since ceramic tile installation ought to be done on a really flat surface. The prep work of the subfloor for all kinds of floor covering installment consists of the basic actions of cleaning and leveling the subfloor. There are mild differences that are gone over above which you should bear in mind to make certain the flooring installment is executed perfectly.

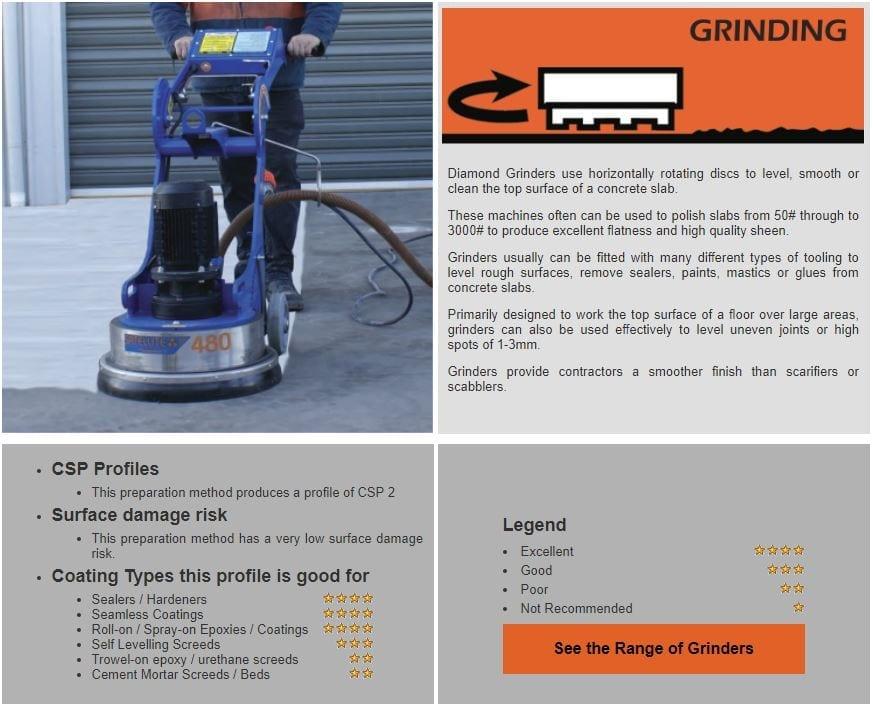

All About Concrete Grinding

There are several kinds of screed but when it comes to flooring installment they all have to be dry enough. It does not add to the architectural efficiency of the flooring.

It is likewise made use of to refer to structural toppings along with putting on surfaces. is screed laid onto a mechanically ready substrate with the objective of maximising prospective bond. is a screed consisting of a screed product including sand up to a 4mm optimum aggregate size. is screed purposefully divided from the substratum by the use a membrane.

This is a type of unbonded screed. is a screed being composed of a concrete in which the optimum accumulation dimension is 10mm (Epoxy flooring). is a screed that is blended to a fluid uniformity, that can be transported by pump to the area where it is to be laid as well as which will certainly stream sufficiently to give the needed accuracy of degree as well as surface area consistency.