In many homes, oatmeal from a Oatmeal manufacturer is a staple food. All age groups enjoy it since it is wholesome as well as adaptable. An oatmeal manufacturer's commitment is the reason behind each mouthwatering dish of oatmeal. These producers turn uncooked oats into superior, consumable goods.

Manufacturing Process

The production of oatmeal includes several intricate stages. The nutritious content of the oats is maintained at every stage. Finding oats of the highest calibre is the first step in the procedure. Typically, these oats are cultivated in areas with weather that is conducive to their growth.

Following harvest, the oats are cleaned. The cleaning process gets rid of pollutants, grime, plus stones. The next step for manufacturers is dehulling, which involves taking the oats' outer husk off. Groats, also known as dehulled oats, are necessary for preparing oatmeal.

After steaming, the groats are sliced or rolled. The type of oatmeal produced is determined by this stage. Steel-cut oats are split into bits, whereas rolled oats are flattened. In contrast, quick oats are prepared more quickly by being pre-cooked as well as dried.

Advanced Machinery

Modern technology is used in the preparation of oatmeal. Modern machinery guarantees production uniformity plus efficiency. These devices precisely sort, process, as well as package oats. Additionally, automated methods reduce production-related contamination hazards.

Quality control is improved by the use of technology. To find flaws, manufacturers use sensors along with scanning equipment. Only the best oats are processed thanks to these technologies. A product that satisfies customer expectations is the result.

Quality Assurance

In the production of oatmeal, quality control is essential. Strict industry standards are adhered to by the manufacturers throughout the whole production process. Oats are tested for moisture content, texture, along with nutritional value.

Protocols for food safety are of utmost importance. Manufacturers follow the rules established by regulatory bodies. Trust in their goods is further strengthened by routine certifications plus audits. This dedication guarantees oatmeal's consistency, safety, as well as nutritional value.

Packaging

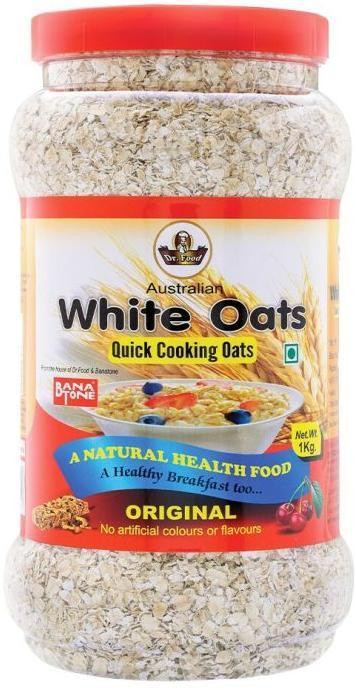

oatmeal is meticulously wrapped after manufacture. The selection of packaging materials aims to prolong shelf life while maintaining freshness. Commonly used are resealable bags plus airtight pouches. To lessen their influence on the environment, some manufacturers also choose to use biodegradable packaging.

Global markets are reached by the oatmeal thanks to distribution networks. These goods are sold in supermarkets, retail establishments, as well as online marketplaces. For prompt delivery, manufacturers frequently collaborate with logistics companies.

Innovation in the Oatmeal Industry

Manufacturers of oatmeal are always coming up with new ideas. They launch new goods as well as flavours to satisfy changing consumer tastes. Organic as well as gluten free oatmeal choices are growing in popularity.

Products made from fortified oatmeal provide extra vitamins plus minerals. Additionally, producers provide quick oatmeal to accommodate hectic schedules. Modern customers are drawn to single serving amounts plus inventive container designs.

Challenges Faced

oatmeal producers encounter several difficulties despite their achievements. The supply as well as production of oats are impacted by climate change. Severe weather can affect quality as well as lower production.

Increasing raw material costs present further difficulties. The total cost is increased by the costs of packaging plus transportation. Manufacturers have to strike a balance between quality as well as pricing.

The demand from consumers for healthier products necessitates ongoing adjustment. To achieve these expectations, manufacturers need to spend money on research. The urge for innovation along with distinction is also fuelled by market competitors.

The Impact on Communities

Manufacturers of oatmeal make a substantial economic contribution to their communities. They generate employment in distribution, processing, plus farming. By buying oats locally, many firms help local farmers.

Manufacturers frequently provide funding for educational initiatives on sustainable farming. These programs enhance farming methods and productivity. The partnership improves ties between farmers and industry.

The Future

The production of oatmeal appears to have a bright future. The demand for oats is driven by growing health consciousness. It is anticipated that manufacturers will continue to broaden their product offerings.

Efficiency will continue to be improved by technological developments. One major area of concentration will continue to be sustainable practices. More creative methods will probably be used by manufacturers to satisfy demand worldwide.

An Oatmeal manufacturer is essential to the delivery of this wholesome food. From sourcing to packing, each stage of the process is essential. The industry is shaped by its dedication to innovation, sustainability, as well as quality. Manufacturers will continue to adjust to satisfy changing customer tastes.