Introduction

Harmonic drive developed a unique gear tooth profile that optimizes the tooth engagement. This tooth profile enables up to 30% of the total number of teeth to be engaged simultaneously. Additionally, the large tooth root radius increases the tooth strength compared with an involute tooth. Harmonic Drives have been employed in a variety of applications such as military and aerospace use. Harmonic gearbox is also known as Strain Wave gearbox. Harmonic gearing is a type of mechanical gear system that uses a flexible spline with external teeth, which is deformed by a rotating elliptical plug to engage with the internal gear teeth of an outer spline.

Harmonic gearbox came with its attractive features like compactness and light weight, High gear ratio. It comes with reconfigurable ratios within a standard housing. Harmonic reducer has a high torque capability with coaxial input and output shafts. The one of the main feature of harmonic drive reducer is, it comes with no backlash. It can provide reduction but can be also used to increase rotational speed.

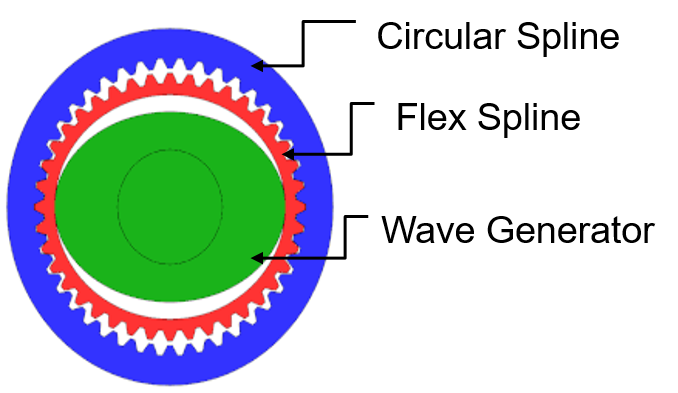

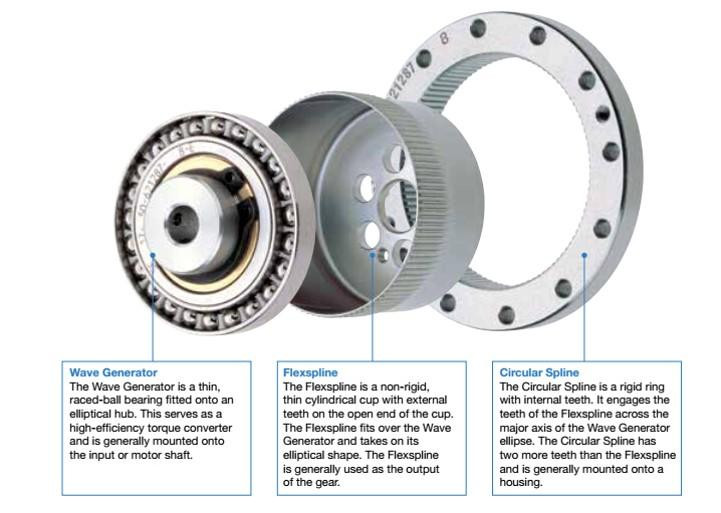

Harmonic drive components

The mechanism of Strain wave drive consists of a toothed mechanism comes with 3 components i.e. Circular spine, Flex spine, Wave Generator.

The circular spline is a solid steel ring with internal teeth. The flex spline is a flexible steel cylinder with external teeth. The drive is executed by the wave generator, It’s a thin-race ball bearing that is fitted onto an elliptical plug. The elliptical shape of the wave generator helps the teeth of the flexspline to engage circular spline at two regions at opposite ends of the major axis of the ellipse.

Applications of Harmonic Gearbox

Harmonic gearbox can be used in any gear reduction application where small size, low weight, zero backlash, very high precision and high reliability are required. Examples include aerospace applications, robotics, electric vehicles, medical x-ray and stereotactic machines, milling and lathe machines, flexo-printing machines, semiconductor equipment, optical measuring machines, woodworking machines and camera head pans and tilt axes. The Harmonic gear box is very useful when the axis moments are required for example in Robot arm.

SMD Harmonic Gearbox with Solid and Hollow Shaft

SMD gearbox is a Taiwan based solution provider of gearboxes. They have their overseas office in Pune, Maharashtra. Their customer base is scattered all around the world. SMD harmonic reducer comes in two variants with solid shaft and hollow shaft. SMD provides an integrated solution to its customer as per their application need. They have expert technocrats who helps the customer in automation process.

To know more how SMD gearbox can help you in your system automation visit our website https://www.smdgearbox.com/harmonic-gearbox-with-solid-shaft-end. If you think we are suitable your system automation team feel free to write us on +91 7030669818 You can visit our Facebook or LinkedIn page. Our Overseas office in India is at A - 51, H Block, MIDC, Pimpri - Chinchwad, Pune – 411018, MH, India.

CONTACT US

Head Quarters

SEIMITSU MOTION DRIVES CO. LTD. (Taiwan)

No. 339, Taishun Rd., Taiping Dist., Taichung City, Taiwan

Mobile No : +886 (09) 67388376

Mail ID: sales@smdgearbox.com

Head Office (Overseas)

SEIMITSU MOTION DRIVES PVT. LTD. (India)

A - 51, H Block, MIDC, Pimpri - Chinchwad, Pune – 411018, MH, India. Mobile No : +91 7030669818 Mail ID: sales@smdgearbox.com