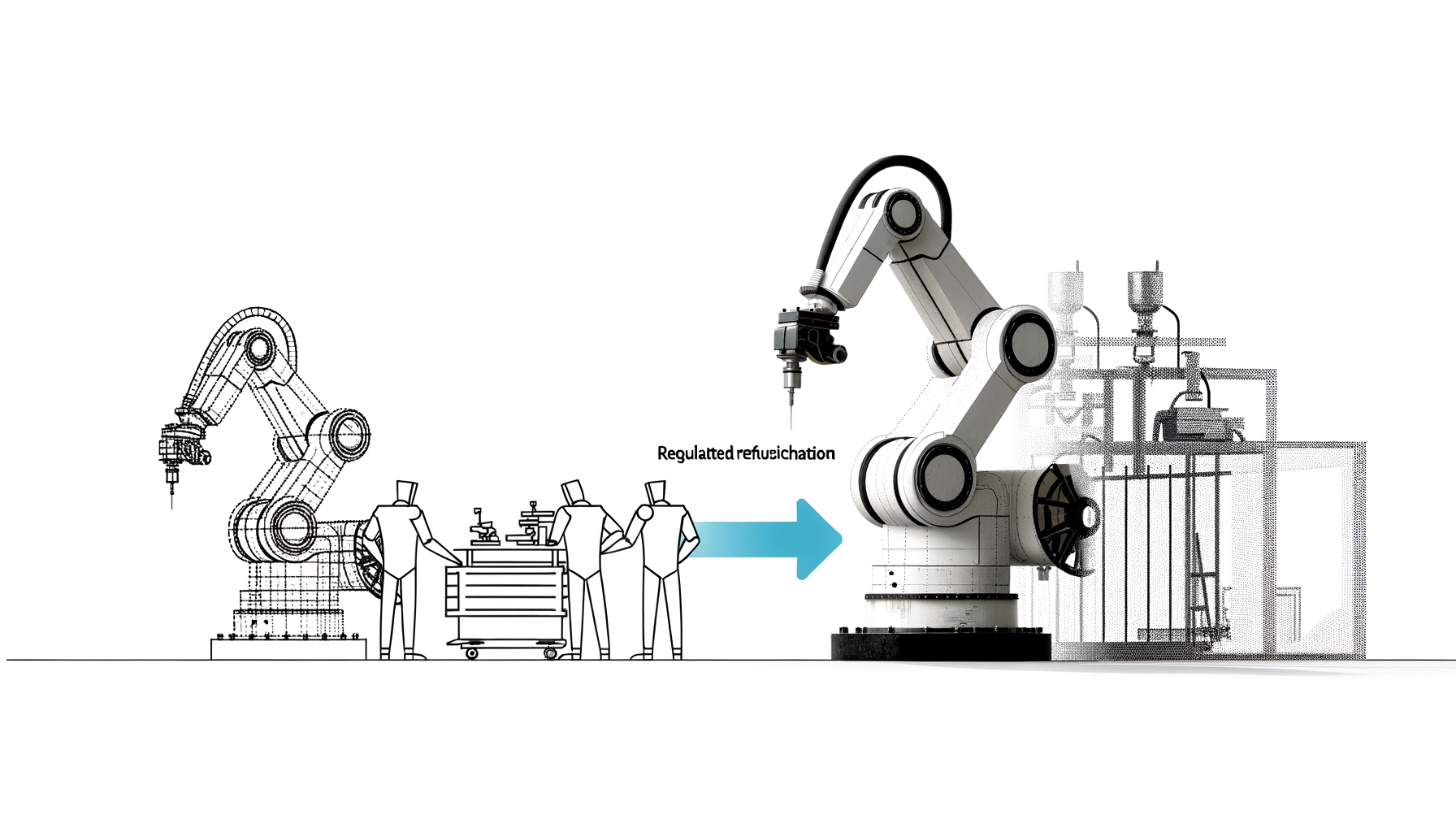

In today's world, sustainability isn't just a buzzword; it's a pivotal part of strategic growth in industries across the board. With industrial robotics at the heart of modern manufacturing, companies are finding innovative ways to improve sustainability and operational efficiency. Among these innovations, regulatory standards encouraging refurbishment practices have become an essential part of the landscape. They provide a valuable framework aimed at maximizing the lifecycle of these expensive machines, minimizing waste, and enhancing operational productivity.

Understanding Industrial Robotics Refurbishment

Before diving into regulatory impacts, it's important to grasp what refurbishment of industrial robotics involves. Simply put, refurbishment is the process of renewing or restoring industrial robots to ensure their reliability and efficiency. It involves comprehensive diagnostics, repair, re-testing, and sometimes, upgrades to make machines almost as good as new.

The primary objectives of refurbishment include:

- Lifecycle Extension: By refurbishing robots, their operational lifespan can be doubled or even tripled.

- Cost Efficiency: Refurbishing costs considerably less than purchasing new equipment, making it a cost-effective choice for businesses.

- Resource Conservation: By minimizing the need for new materials, refurbishment supports resource conservation efforts.

Regulatory Standards: Setting the Foundation for Refurbishment

With the growing emphasis on sustainability, several countries and regulatory bodies have issued guidelines and standards to encourage refurbishment. These standards dictate how robots should be refurbished to ensure they meet specific safety, operational, and environmental criteria.

Key frameworks include:

- The Circular Economy Model: Advocated by the European Union, this model promotes design and business practices that enable repair and refurbishment.

- ISO Standards for Robotics: Standards like ISO 8373 and ISO 10218 ensure that refurbished robots meet stringent safety and functionality criteria.

- Eco-Design Directives: Enacted in various jurisdictions, these directives mandate manufacturers to design products considering their entire lifecycle, thus making refurbishment straightforward.

The Multi-Faceted Impact of Regulatory Standards

The introduction and implementation of these regulatory standards have led to transformative impacts in the field of industrial robotics:

1. Encouraging Innovation and Competitiveness

- New Markets: With the stipulation of refurbishing robots, companies have pivoted to innovation within constrained conditions.

- Third-party Service Providers: Specialized firms now offer expert refurbishing services to manufacturers and industrial operators.

2. Environmental Benefits

- Waste Reduction: Refurbishment decreases e-waste considerably by offering machines a second life.

- Resource Efficiency: Reducing the rate of new machinery production leads to lower raw material extraction.

3. Enhanced Operational Efficiency

- High-Performance: Refurbished machines are tested to stringent standards promoting reliability.

- Flexibility: Incorporating the newest technology in older machines allows adaptability in evolving production environments.

4. Economic Implications

- Reduced Capital Expenditure: Businesses save on capital investment by opting for refurbished alternatives.

- Employment Growth: A surge in refurbishment demand escalates job creation in specialized repair and maintenance sectors.

Future Outlook: Embracing Sustainable Robotics Practices

The integration of regulatory standards favoring refurbishment is not the endpoint. Instead, it marks the beginning of a sustainable revolution within industrial robotics. The foresight of industry leaders who recognize the broader implications can be transformative:

- Collaborative Partnerships: Organizations and refurbishers must work closely to ensure continuous improvements.

- Legislative Development: Advocates and policymakers play a crucial role in developing comprehensive legislation as the foundation for sustainable industrial practices.

- Educating Stakeholders: Informing entrepreneurs and workers about the advantages of refurbishment can drive larger acceptance and interest.

Conclusion

Ultimately, embracing a circular approach in industrial robotics through regulatory standards is not only benefiting individual companies but the industry at large. This transition towards refurbishment not only supports global sustainability goals but can also arm businesses with the tools to remain competitive in a rapidly evolving market. As industries continue to adopt and adapt, the marriage of regulatory standards and refurbished robotics will undoubtedly be a beacon for achieving a greener, more sustainable future.

Explore Comprehensive Market Analysis of Industrial Robotics Refurbishment Market

SOURCE-- @360iResearch