Cannabis processing has become a burgeoning industry with the ever-increasing demand for various cannabis-based products, from oils and edibles to topical creams and capsules. To harness the full potential of the cannabis plant, processors face the challenge of effectively breaking down the fat-soluble cannabinoids into smaller particles that can be seamlessly integrated into a wide range of products. This article explores the advantages of using high-pressure homogenization (HPH) as a powerful technology for optimizing cannabis processing.

The Challenge of Cannabis Processing

Cannabis contains a diverse array of chemical compounds, including cannabinoids, which are responsible for its therapeutic and psychoactive effects. However, these cannabinoids are naturally fat-soluble, making it difficult to mix them with other ingredients or emulsify them. The key to success in cannabis processing lies in breaking these cannabinoids into extremely small particles, allowing for their uniform dispersion in various formulations.

High Pressure Homogenization (HPH) as the Optimal Solution

High-pressure homogenization, a technology that employs extreme pressure to disrupt particle structures, has emerged as a superior method for processing cannabis. Here are some of the key advantages of HPH in cannabis processing:

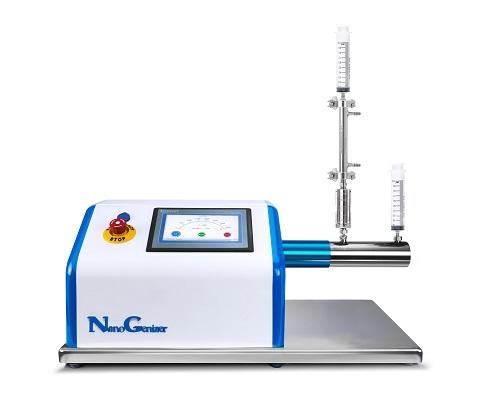

NanoGenizer High Pressure Homogenizer

Efficient Particle Reduction: HPH effectively breaks down the cellular bonds within cannabis compounds, reducing them to nano-sized particles. This facilitates the creation of stable emulsions or suspensions, allowing for uniform distribution of cannabinoids in a wide range of products.

Versatility: High-pressure homogenization can be tailored to handle various sample types and sizes. Whether you're working with small batches or large volumes, HPH provides consistent results, making it suitable for a diverse range of cannabis products.

Enhanced Bioavailability: HPH technology significantly improves the bioavailability of cannabis products, which means that lower amounts of active ingredients are required to achieve the desired effects. This not only reduces production costs but also enhances product quality.

Improved Consistency: HPH ensures a more consistent and predictable result, vital for creating high-quality cannabis products with a uniform appearance, taste, and effect.

High-pressure homogenization technology offers an efficient and cost-effective solution to the challenges of cannabis processing. By breaking down fat-soluble cannabinoids into smaller, more manageable particles, HPH enables the creation of stable emulsions and suspensions, making it easier to incorporate cannabis into a wide array of products. As the cannabis industry continues to evolve, embracing innovative processing techniques like high-pressure homogenization will be essential for producing high-quality, consistent, and bioavailable cannabis-based products that meet the demands of an ever-expanding market.