Does The Asphalt Mixing Equipment Belong To The Concrete Machinery?

The operation condition of asphalt mixing station is related to many aspects, in order to save the energy consumption problem of asphalt mixing station, staff should find an effective solution from the problems encountered in practical work.

The operation condition of asphalt mixing station is related to many aspects, in order to save the energy consumption problem of asphalt mixing station, staff should find an effective solution from the problems encountered in practical work.

In the operation of asphalt mixing station, it is necessary to consume a lot of fuel, and the moisture content in raw materials will be related to the utilization efficiency of resources.

With statistics, for every 1% increase in the water content of the stone, the energy consumption of the equipment increases by about 12%.

Therefore, if you want to save energy consumption, then the staff must properly control the water content of raw materials, you can take some measures to optimize the quality of raw materials and so on.

.

Q: Some put Asphalt Batch Mix Plant mixing equipment into the pavement machinery asphalt concrete is concrete?

A: Asphalt concrete is asphalt concrete by manual selection with a certain level of composition of the mineral (gravel or crushed gravel, stone crumbs or sand, mineral powder, etc.) and a certain proportion of road asphalt materials, in strict control of the mixing of mixed materials.

The atomization effect of fuel is also closely related to the problem of energy consumption.

Therefore, maintaining a good atomization state will improve the efficiency of fuel use.

Usually, the manufacturer will adjust the mixer atomization state in advance, but after a period of use, because it will be affected by impurities, so the staff of the asphalt mixing station should be installed a filter to ensure a good atomization state.

.

When the metering work is over, it is not possible to show up on the equipment, so as not to cause the phenomenon of the bucket caused by foreign bodies.

Weighing process, each item is based on the corresponding weighing sensor in the operation, so the force must be constant, making the sensor sensitive.

Then the measures that should be taken are: 1, strict control of the quality of materials, so as not to affect the late production of electric putter; 2, assume some drainage facilities to enhance the drainage capacity of the site, as far as possible to reduce the moisture content of the material, so as to enhance the efficiency of the asphalt mixer, save the asphalt mixing station fuel consumption;

.

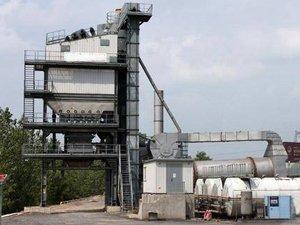

Asphalt mixing equipment is placed in the pavement machinery

Concrete, refers to the cementitious material will aggregate aggregates into a whole of engineering composites collectively.

The commonly spoken term of concrete refers to the use of cement as cementitious material, sand, stone as a aggregate, and water (plus or without admixture and admixture) in a certain proportion of cooperation, by stirring, molding, curing of cement concrete, also known as ordinary concrete.

It is widely used in civil engineering.

n

Asphalt mixing equipment in the measurement operation, should keep the movement of each discharge door flexible, whether it is turned on or off, at the same time, but also to ensure the smooth nature of the discharge port, must not have sediment presence, so as to ensure that the metering material can be quickly and evenly shed.

In order to ensure the quality of asphalt agitation, it is necessary to accurately control the amount of various raw materials, which is indispensable to the metering device, but do not know the asphalt mixing equipment metering when you need to pay attention to what? Take a look at it together.

Choosing the right fuel is critical to improving combustion efficiency.

Most of the fuel on the market today includes liquid fuels, gaseous fuels and solid fuels.

In comparison, the combustion efficiency of the gas is the highest, the calorific value is high, and it is relatively stable, the disadvantage is the higher cost, so it is often used in small and medium-sized asphalt mixing station.

And the stability of solid fuel is poor, easy to cause accidents, for its temperature control is also more difficult, so the use of very little.

Liquid fuel has high calorific value, low impurity content, good controllability and cheaper cost.

.

(3) Check the alignment of the cylinder body frequently.

Loosen the thrust roller first to check the degree to which the simplified energy can move within the length range of the slot on the support bracket.

Then start the drying cylinder, if the simplified front and rear movement, to check whether all the support rollers have been adjusted integrity.

If the supporting roller has been adjusted for integrity, and the cylinder gradually tends to feed end, then the thrust roller is temporarily biased (so that the drying cylinder is in the correct working angle), until the correct adjustment has been achieved.

If the cylinder gradually tends to unload the end, the thrust roller is adjusted in the opposite direction.

.

Aggregate directly from the Rolling Stone has almost constant water content, while the aggregate taken from the open-air yard has a higher water content, and the water content of different piles is also very varied.

Therefore, aggregates are best taken from the same source.