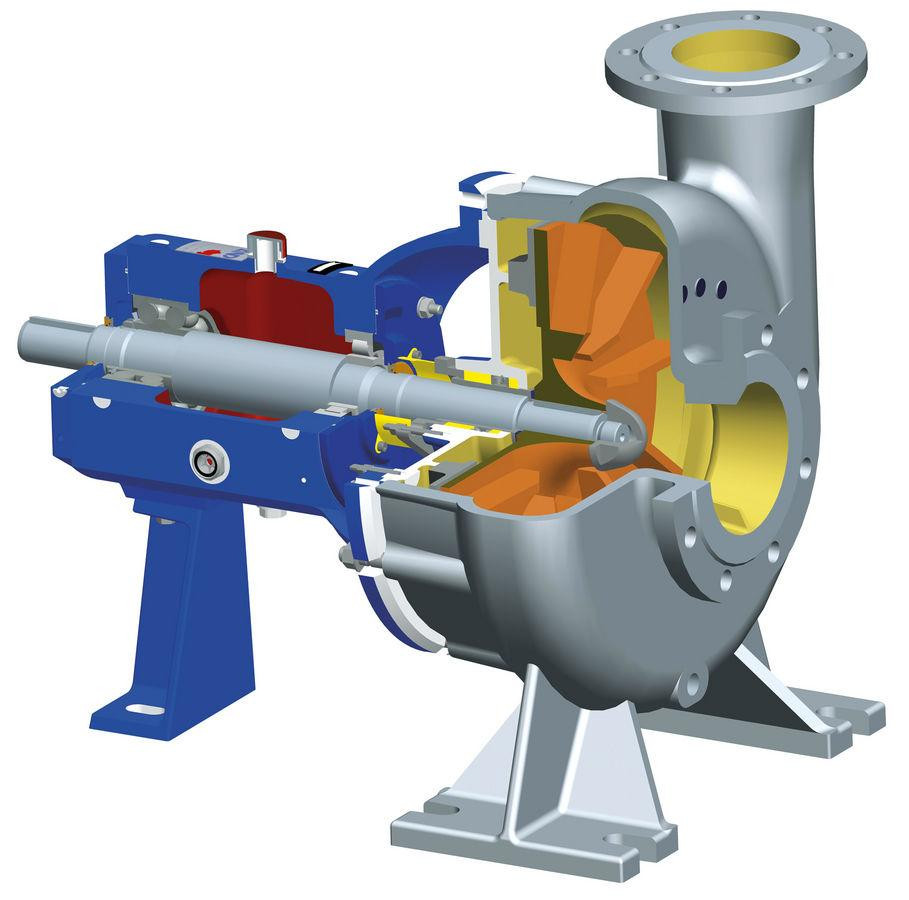

The impeller, in a Centrifugal Pump, has a single nozzle that flickers the fluid. The fluid is then moved by the shaft, which is powered by an engine. The engine may be an electric motor, diesel drive, or hydraulic motor. The shaft is concentric with the impeller and the casing. The pump's cover and outlet are connected with the suction pipe. The latter connects to the height at which the fluid is to be transferred.

The casing of a centrifugal pump is fitted with a single spiral tube aerator. There are two main types of spirals, the narrow and wide ones. The casing is made of the same materials as the impeller, though different materials are often used for different applications. A built-in flat seal ensures that the cover and casing are sealed against one another. The casing also features a gasket to prevent water from escaping from the pump.

A centrifugal pump is made of an impeller that is fitted with a single suction nozzle. The impeller is driven by a rotating shaft that is powered by an electric motor, diesel drive, or hydraulic motor. The motor energizes the fluid and accelerates it. This increases the pressure inside the fluid, resulting in a charge. A charge is created by the accelerated fluid, which is what makes a centrifugal pump work.

Read in detail about Centrifugal Pump- shorturl.at/W3569