In the dynamic landscape of modern manufacturing, efficiency, precision, and innovation stand as pillars dictating success. Siemens Tecnomatix, a flagship suite of digital manufacturing solutions, has emerged as a game-changer in revolutionizing industrial operations. From optimizing production workflows to enhancing product quality and reducing time-to-market, Tecnomatix is a powerhouse that empowers industries across the globe.

Navigating the Diverse Universe of Siemens Tecnomatix Software

Siemens Tecnomatix stands as a robust suite offering a plethora of tools tailored to optimize and revolutionize various aspects of industrial operations. This comprehensive platform encompasses a wide array of software modules, each designed to address specific challenges across the manufacturing lifecycle. Let’s delve into the diverse types of Tecnomatix software that cater to different facets of the manufacturing process.

1. Tecnomatix Process Simulate

Purpose: Process Simulate is a powerful tool aimed at simulating and validating manufacturing processes in a virtual environment. It allows for the creation of detailed simulations of production lines, enabling optimization, validation, and visualization of assembly processes before actual implementation. This minimizes errors, reduces production downtime, and enhances overall efficiency.

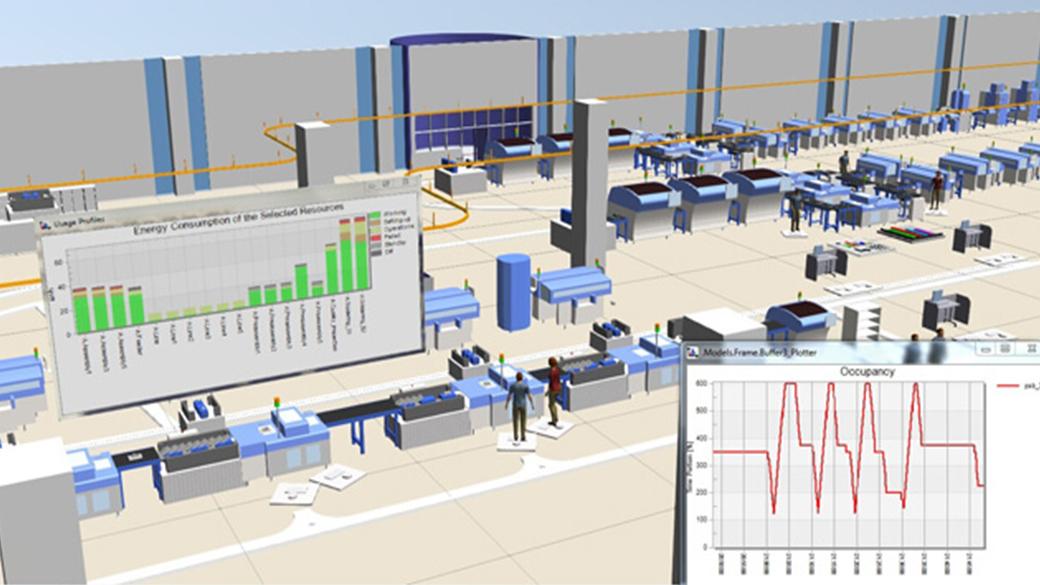

2. Tecnomatix Plant Simulation

Purpose: Plant Simulation is focused on optimizing production systems and logistics by creating digital models of factories or warehouses. It facilitates the analysis and optimization of layout designs, material flow, and resource allocation, aiding in the identification of bottlenecks and enhancing throughput.

3. Tecnomatix Jack

Purpose: Jack is a specialized software within Tecnomatix used for human simulation and ergonomics analysis. It aids in the design of workstations by simulating human actions, ergonomics, and safety considerations. This ensures that the workplace is optimized for efficiency while prioritizing the well-being of workers.

4. Tecnomatix Quality

Purpose: Tecnomatix Quality focuses on quality management throughout the manufacturing process. It enables companies to create quality plans, perform inspections, and manage non-conformances efficiently. This module helps in maintaining and enhancing product quality while adhering to industry standards.

5. Tecnomatix Robotics and Automation

Purpose: This module is dedicated to the simulation and programming of robotic systems used in manufacturing. It allows for the design, validation, and optimization of robotic workcells

, streamlining automation processes and enhancing productivity.

6. Tecnomatix Assembly Planning and Validation

Purpose: Assembly Planning and Validation software aids in the planning and validation of complex assembly processes. It allows for the creation and optimization of assembly sequences, ensuring seamless operations and reducing assembly time.

7. Tecnomatix Manufacturing Process Management

Purpose: This module focuses on the management and optimization of manufacturing processes by providing tools for process documentation, standardization, and workflow management. It enhances collaboration and ensures consistency across operations.

8. Tecnomatix Digital Manufacturing Engineering

Purpose: Digital Manufacturing Engineering enables the creation of detailed digital twins of products and production processes. It aids in the optimization of product design for manufacturability and supports the integration of design and manufacturing data.

9. Tecnomatix Machining

Purpose: Machining software within Tecnomatix specializes in the simulation and optimization of machining processes. It aids in toolpath planning, CNC machine simulation, and analysis, ensuring efficient and error-free machining operations.

10. Tecnomatix Process Engineering

Purpose: Process Engineering software is designed to streamline and optimize engineering processes by providing tools for data management, analysis, and collaboration. It helps in managing engineering changes and maintaining process consistency.

Harnessing the Power of Tecnomatix

Each type of Tecnomatix software plays a pivotal role in enhancing efficiency, quality, and innovation within manufacturing environments. By leveraging these diverse modules, industries can streamline operations, reduce costs, minimize errors, and adapt swiftly to market demands.

The key to reaping the benefits lies in understanding the specific needs of the manufacturing process and selecting the appropriate Tecnomatix software to address those requirements. Furthermore, integration and collaboration among different Tecnomatix modules can amplify their collective impact, unlocking new levels of productivity and competitiveness.

The Future of Tecnomatix

As technology continues to evolve, Siemens Tecnomatix is poised to advance further, incorporating advancements in artificial intelligence, machine learning, and IoT integration. This continual evolution will empower manufacturers with even more sophisticated tools to drive efficiency, sustainability, and innovation.

The diverse spectrum of Tecnomatix software modules stands as a testament to Siemens’ commitment to revolutionizing manufacturing operations. By harnessing the capabilities of these tools, industries can embark on a journey towards unparalleled efficiency and excellence in the ever-evolving landscape of digital manufacturing.

Understanding the Force Behind Tecnomatix

At its core, Tecnomatix embodies a fusion of cutting-edge technologies such as simulation, digital twins, and advanced data analytics. This amalgamation empowers manufacturers to visualize, simulate, and optimize production processes in a virtual environment before execution in the physical realm.

1. Simulation and Digital Twins:

Tecnomatix leverages the concept of digital twins, creating virtual replicas of physical assets or processes. This allows for detailed simulations, enabling real-time analysis of potential scenarios, identifying bottlenecks, and streamlining operations without disrupting the actual production line.

2. Process Optimization:

Through comprehensive process optimization tools, Tecnomatix enhances efficiency by fine-tuning manufacturing processes. From assembly line layout design to logistics planning and resource allocation, this platform enables meticulous planning for optimal performance.

3. Data-Driven Insights:

Data is the new currency, and Tecnomatix harnesses it effectively. By collecting, analyzing, and interpreting real-time data from various sources within the manufacturing ecosystem, it provides actionable insights for continuous improvement.

Harnessing the Benefits

The advantages of embracing Siemens Tecnomatix are manifold:

1. Reduced Time-to-Market:

By facilitating faster design iterations and minimizing production errors through simulations, Tecnomatix significantly cuts down the time required to launch new products into the market.

2. Enhanced Quality Control:

The ability to simulate and predict potential flaws in the production process allows for proactive quality control measures, ensuring higher product quality and reliability.

3. Cost Efficiency:

Optimization of processes and resources leads to reduced operational costs and waste, maximizing the overall profitability of manufacturing operations.

4. Agility and Flexibility:

Tecnomatix empowers manufacturers to adapt swiftly to market changes by enabling quick reconfiguration and optimization of production lines.

Implementing Tecnomatix for Success

Maximizing the potential of Tecnomatix requires a strategic approach:

1. Comprehensive Training:

Investing in comprehensive training programs for the workforce ensures that employees are adept at utilizing Tecnomatix to its fullest potential.

2. Integration and Collaboration:

Seamless integration of Tecnomatix with other enterprise systems fosters better collaboration among different departments, streamlining workflows and enhancing productivity.

3. Continuous Improvement:

Embrace a culture of continuous improvement by leveraging Tecnomatix's data insights. Regularly analyze performance metrics to identify areas for enhancement and innovation.

The Future of Manufacturing with Tecnomatix

As Industry 4.0 continues to shape the future of manufacturing, Siemens Tecnomatix Software stands as a beacon of transformation. Its evolution will likely include further advancements in artificial intelligence, machine learning, and IoT integration, empowering manufacturers to achieve unprecedented levels of efficiency and competitiveness.

The power of Siemens Tecnomatix in revolutionizing manufacturing efficiency cannot be overstated. By leveraging its capabilities, industries can not only streamline operations but also pave the way for a more sustainable and innovative future. With Tecnomatix at the helm, the journey towards manufacturing excellence becomes not just a possibility, but an achievable reality for those ready to embrace its potential.