CNC engraving machine and laser engraving machine are both computerized engraving machines. CNC engraving machine is the index control engraving machine, CNC engraving machine, CNC engraving machine or CNC engraving machine, laser engraving machine refers to the laser engraving machine, both need computer control for engraving. Preparation of image files or road maps are usually entered into the computer upon completion. In this sense,laserpecker compact laser engraver both are machines. Although digital control systems are used, they work differently and have different mechanical structures. In contrast, the structure of a CNC engraving machine is relatively simple. By controlling the computer numerical control system, the machine automatically selects the appropriate drill and cutter to carve along the X, Y and Z axes of the machine.

Many people have been misunderstanding CNC engraving machine and laser engraving machine as the same thing. In fact, there are many differences between these two equipment machines.

Laser engraving is based on CNC machine technology and the laser is a processing medium. The laser source emits laser light and the CNC machine tool system controls the laser head and motor motion optics on the laser head,laserpecker 11 mirrors, lenses, etc., so that the focus is on the X, Y and Z on the axes of the moving machine. This material is immediately irradiated by the laser. The physical modification of melting and vaporization is achieved for machining purposes.

Difference between CNC engraving machine and laser engraving machine

Laser engraving, not in contact with the surface of the material, is not subject to mechanical movement, surface deformation, and usually does not require fixation. The utility model is not affected by the flexibility of the material, facilitating the use of soft materials. High precision, fast speed, wide range of applications.

CNC is short for computer numerical control, an automated machine with a programmed control system. The control system can logically process and decode programs using control codes or other symbolic instructions to enable the machine to move and machine parts. A CNC engraving machine is a power tool that accomplishes machine engraving through CNC control.

Laser engraving machines use lasers to alter traditional materials by studying high temperature environments. Therefore, similar to combustion, different materials of different building materials in the operation and management of the process of combustion chemical reaction will have different effects, depending on the melting point of the material. Cutting effects are analyzed differently, and fumes and odors are also produced during industrial development.

CNC engraving machines work on spindles and drills, which are similar to drills and produce a lot of dust when working, but do not produce smoke and odor.

Laser engraving is a non-contact etching that protects the surface of the engraved material from scratches. In addition the laser beam is very fine, so the slit is small and suitable for precision cutting. Cutting with a CNC engraver depends on the diameter of the cutter head. There are many routes. Different engraving machines are used for different materials.

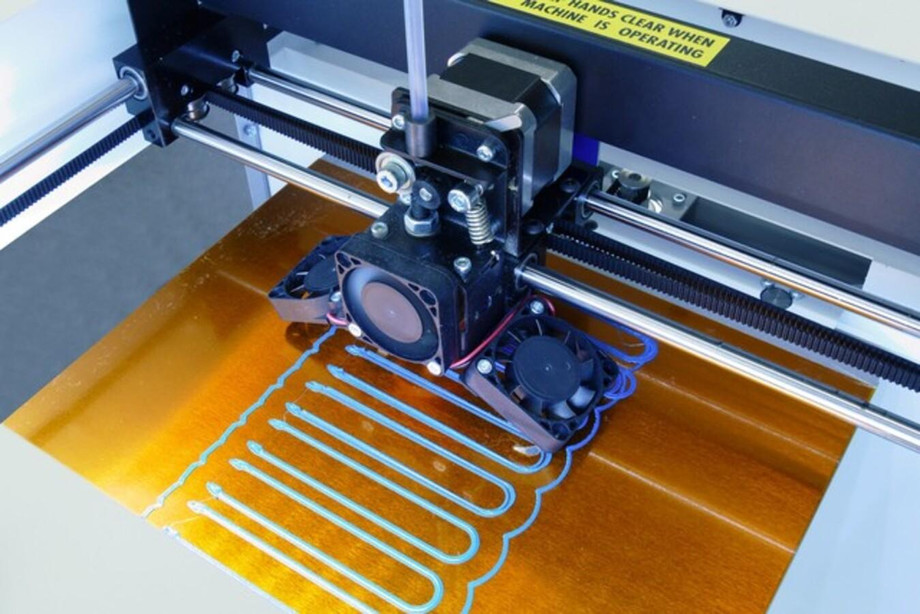

The laser engraving machine delivers the laser by focusing the focal point through an optical system onto a high power density laser beam. The laser beam irradiates the surface of the workpiece to the melting or boiling point. Simultaneously, a high-pressure gas with the beam is blown away or evaporated from the melting place. With the relative position of the beam and the movement of the workpiece, the material eventually forms a cutting mark for engraving purposes.

A CNC engraving machine is a high-speed rotary engraving machine driven by a motor spindle. A tool constructed to process material according to the present invention can cut the processed material fixed to the table by automatic engraving, and a variety of two-dimensional or three-dimensional table tops with embossed graphics or text can be realized by the automatic engraving operation.

The greatest degree of difference between the laser engraving machine and CNC engraving machine is mainly because the tool of the laser engraving machine is a more complete optical system components, while the CNC engraving machine tool is through a number of different entities. The laser etching machine utilizes the high energy of the laser to complete the cutting or engraving of the material, while the CNC engraving machine uses the information high speed rotary tool to cut and engrave the material, so for the engraving of the two methods of operation of the action development of the object has a different.

Laser engraving machine can only cut and shallow engraving on the surface of the object, and can carve marble tombstone portrait. CNC engraving machine can cut or enlarge relief, such as some wooden furniture relief.

Laser engraving machine can be divided into non-metal laser engraving machine (CO2 laser engraving machine) and metal laser engraving machine (fiber laser engraving machine). Non-metal engraving machine can be divided into: ordinary engraving machine and non-metal laser marking machine. Metal engraving machine can be divided into metal laser marking machine and metal engraving and cutting machine.

Metal laser engraving materials: metal plate, acrylic, plexiglass, glass, fabric, leather, paper, bamboo, film, canvas, etc..

Non-metal through the laser for engraving technology for a variety of wood products, paper, leather, cloth, organic combined with glass, epoxy resin, acrylic, wool, plastic, rubber, ceramic tile, marble, round stone, bamboo products and other materials.

CNC engraving machine application research scope to carry out a wide range of applications in a variety of different fields and industries, suitable for engraving and cutting a variety of active materials (except low melting point materials).

CNC engraving machine can be applied to furniture, decoration, musical instruments, handicrafts, molds, signs, souvenirs and processed materials, including wood, foam, acrylic, plastic, PVC, ABS, stone, imitation stone, marble, aluminum plate, copper, aluminum and other soft metal materials.

Simply put, a laser engraving machine uses laser melting or burning to engrave, while a CNC engraving machine uses digital technology to control the cutting machine or laser and ultrasonic heads to engrave. Laser engraving machines can be CNC engraving machines. CNC engraving machine can also be equipped with laser head for engraving.

Related articles:

PCB laser engraving machine, laser engraving machine for circuit boards