Do you know the factor for which your business can succeed? What contributes to your sales and revenue growth? The answer is maintaining your list and selecting the appropriate metric and KPI for inventory management. Inventory management plays a vital role in increasing business health.

Inventory Management KPI can give you information and help you to manage your business process by streamlining your processes, strengthening your supply chain, improving customer satisfaction, and supporting company-wide goals and improvements.

There are many inventive KPIs that you can use to measure your performance, here in this article we are introducing some of them that increase your business performance from low cost to high profit.

What Are Inventory Metrics?

Inventory metrics are the key element which helps to increase business performance and they can measure it every week, month, quarter or year. It also helps in estimating the future trend of the business.

Inventory management KPIs are important because they are used to track warehouse performance and how inventory is ordered, managed, and commissioned. Inventory management KPIs are important for measuring the progress of supply chain objectives and identifying areas for improvement.

Why Inventory Management KPIs Matter

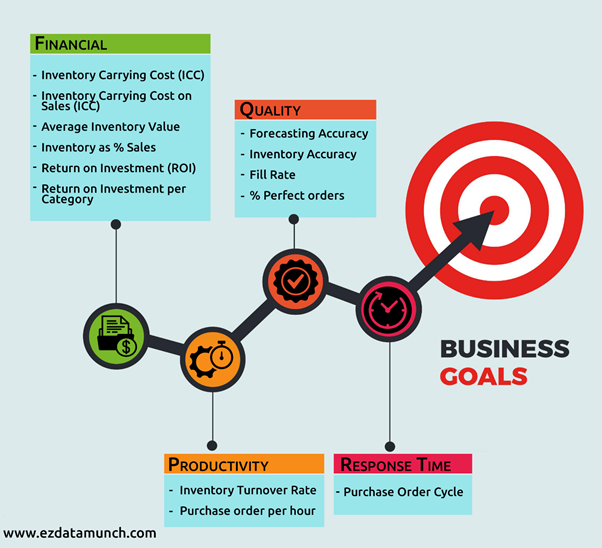

For every successful business, KPIs have a major role. This not only provides a topic to a person, but also helps to increase the efficiency of the business. KPI in inventory management is giving a deep and lasting positive impact on many important aspects such as financial health, business reputation and overall operational efficiency.

KPIs reduce confusion and uncertainty from your processes by establishing clear criteria for performance within specific timeframes. Inventory KPI's metrics are designed to use data collection and analysis to provide insights for continuous improvement across the board.

Ways to choose inventory metrics for warehousing?

- Choosing KPIs requires being smart. We should eliminate KPIs which are difficult to calculate and measure.

- KPIs ensure that all contribute to the strategic goals of your organization, e.g. Are these customer service goals, development strategies, or profitability objectives?

- KPIs will influence how employees do their jobs, so ensure the metrics you choose to promote true collaborative behavior and avoid any issues that encourage competition between departments.

After selecting and placing KPIs, the next task is to track and monitor KPIs in your business on a regular basis. Employees need to understand their importance and how they personally see performance affected. Appreciate them when you are doing well and respond when you need to improve performance to keep everyone motivated towards the same goal.

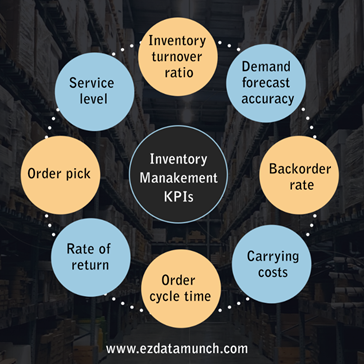

Common inventory management KPIs for your business

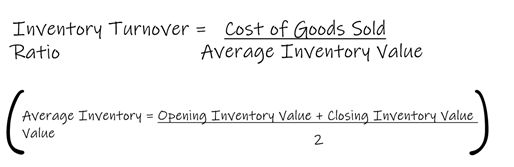

Inventory turnover ratio

Inventory turnover ratio suggest number of times stock is sells and replaces during a particular period. It usually measured for predefined time period or usually a year.

Way to calculate inventory turnover ratio:

Demand forecast accuracy

Demand forecasting accuracy is the process of determining the accuracy of forecasts made about customer demand for a product.

The advantage of using demand forecasting accuracy KPIs is to ensure stock availability so that you can maximize sales and keep the customer happy.

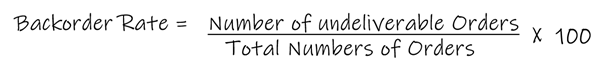

Backorder rate

Backorder rate is the percentage of orders that cannot be delivered at the scheduled time but that will be delivered at a later date. This KPIs also helps to track number of delayed order due to out of stock.

This can be calculated as:

Carrying costs of inventory

Carrying inventory costs is the amount a business spends on keeping inventory over a period of time. This includes warehousing costs such as rent, utilities and salaries, financial costs such as opportunity costs, and inventory costs related to perishability, shrinkage, and insurance.

Order cycle time

Order cycle time (OCT) refers to the average time required to fulfill customer orders. This KPIs can be an indicator of how efficiently you prepare and process orders. The less time you order, the less stock you need to carry, which reduces costs and improves your turnover ratio.

Rate of return

Rate of return KPI use to track the percentage of orders that are returned.

Ways to calculate Rate of return:

Order pick, pack and dispatch

Order Pick, Pack and Dispatch KPIs are used top-level, as you require, and your system allows. This step involves locating, packing and shipping a product. Pick, pack and dispatch KPIs can indicate where your warehouse processes are particularly strong and where they need improvement.

Service level

The service level measures whether an inventory was out of stock when it was requested for delivery, leading to an incomplete order.

Inventory Dashboard Example

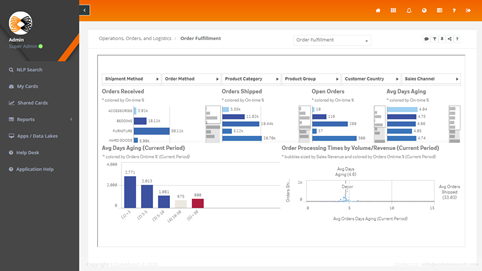

Order Fulfilment

We have a good depiction of inventory management performed with the help of business intelligence and data visualization. Order fulfillment is the entire process from the point of sale inquiry to the delivery of a product to the customer in the most general sense. Order Fulfillment covers the entire process of receiving, processing, packing, picking and shipping orders online to customers.

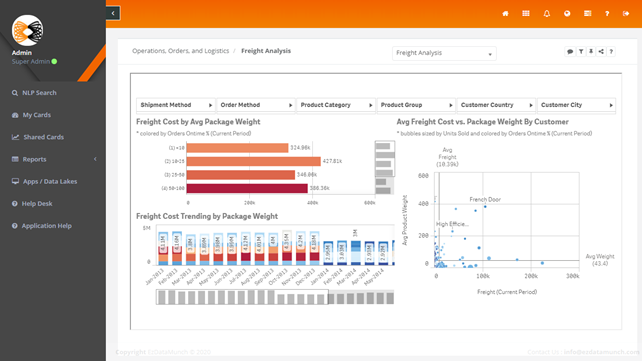

Freight Analysis

The inventory analysis dashboard helps management teams make a reliable and accurate informed decision. You get a complete overview of your shipping processes with an operational dashboard that gives you a breakdown of services, shipping volume, cost per route, usage, and more.

Conclusion

In this blog, we have discussed the importance of inventory metrics and KPIs and discussed several KPIs that we use the most. We believe that selecting a KPI is smart work and only select those that depend on your needs, choose the KPI that makes the most sense for your business.

If you are unable to select the required KPI, then using some regular KPIs such as inventory turnover rate, rate of return, etc. will also help your business. You can also take advantage of EzDataMunch Lifetime Free Trial Access and to manage your business needs and select KPIs.