We know that rework, surface preparation and inconsistent seams are time and budget as well as occupational safety drains. Our Laser Metal Welding Machine addresses these pain points by cutting prep work, delivering fine seams with minimal heat input, and reducing cycle time so teams can focus on throughput and quality.

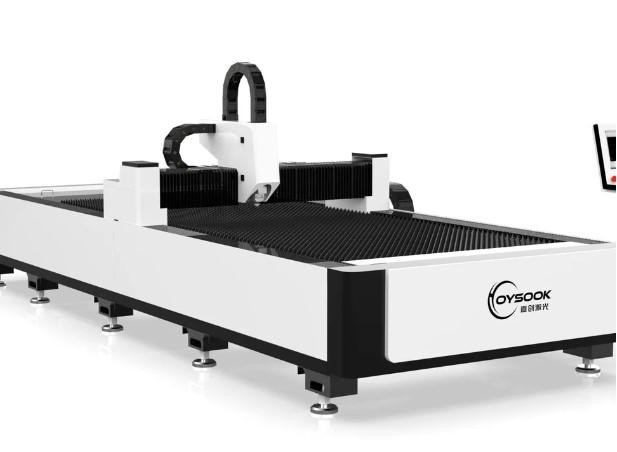

Laser Welding Machine for Stainless Steel — precise, fast, low-heat

Manufacturers need good appearance welds that can withstand the stress. Our solution equips flexibility in the hands with the power of industry. HYLW-A Series has 1500W, 2000W and 3000W options and a welding thickness range of 0.8-10mm, thus applicable to both thin sheets and structural parts.

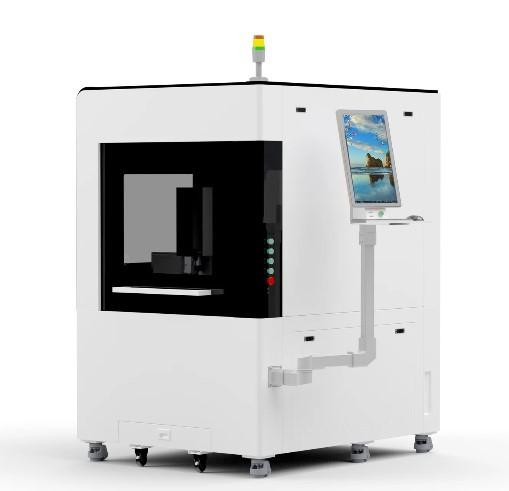

One machine, four functions

The 4-in-1 integrates welding and cutting, laser cleaning and seam finishing into a single cabinet. The consequence of this is a reduced number of machines, reduced floor area and quicker changeovers in mixed production runs. It is a water-cooled system and it performs best with nitrogen or argon shielding gas.

Why this Laser Metal Welding Machine stands out

Our three wins are easier to measure: reduced number of rejects, less operator time per part, and no secondary machining in most situations since the weld bead is smooth and cosmetically acceptable immediately after the machine. The source of fibre focuses the energy, and provides a small heat-affected zone, maintaining corrosion resistance in stainless materials.

Practical benefits on the shop floor

-

Cleaner welds: automated laser cleaning eliminates rust and paint and welds before cutting, eliminating manual preparation.

-

Greater cycle times: high peak power and real-time part positioning reduce per-part time.

-

Energy efficiency: the laser consumes less energy than the traditional arc processes and can reduce operating costs.

Materials, torch and nozzles

The unit deals with iron, steel, aluminium, stainless steel, galvanised sheet, copper and so forth. It is packaged with a Sup23T torch and a variety of nozzle choices, allowing operators to adjust penetration and bead shape to particular alloys and joint geometries.

How it compares to MIG and TIG

Where MIG excels in speed and TIG in finesse, this Laser Metal Welding Machine blends precision and repeatability while reducing distortion. When dealing with stainless work, the laser action focuses and reduces any discolouration and in most instances, eliminates the necessity of grinding or filler.

It is particularly helpful with items that are important in terms of aesthetics, e.g., kitchenware, architectural fittings and consumer goods.

Scale from handheld to Automation

Begin with handheld welding to do prototype and repair, and ramp up to robotic arms in high volume. The HYLW-A Series is capable of robotic integration to allow the shops to transition between manual and unmanned cells without changing the base laser source.

Operators like the fact that this platform yields beautiful welds that do not usually require secondary processing. Since the system is simple to install and use, even teams with years of welding experience can run parts reliably - a real no-welding experience is required on many of the more mundane tasks. For shops that focus on corrosion-resistant assemblies, the Laser Welding Machine for Stainless Steel option delivers consistent, clean seams that preserve finish and strength.

Applications that benefit most

-

Stainless steel food service and kitchen equipment.

-

Auto bracket and small assemblies that require narrow HAZ.

-

On-site on-sheet metal repair.

-

Ornamentation using metals where the ultimate appearance counts.

Conclusion

The HYLW-A Series is a water-cooled, handheld-capable 4-in-1 fibre laser system. It combines cutting, welding, finishing and seam finishing all in a single platform that minimises capital expenditure and streamlines the working process. For shops focused on stainless parts, the Laser Welding Machine for Stainless Steel option delivers high-quality beads with minimal postwork.

Collaborate with HOY SOOK LASER and introduce better first-pass yield to your manufacturing- send.

FAQ

Q: Is the Laser Welding Machine for Stainless Steel safe for thin-gauge panels?

A: Yes. Using proper power, speed and nozzle choice, it welds thin panels and burns through minimally.

Q: What are the power alternatives?

A: HYLW-A Series features 1500W, 2000W and 3000W to fit part size and duty cycle.

Q: Do we require different cleaning devices?

A: No. The combined laser cleaning system cleanses rust, paint and contaminants before welding.

Q: Is one able to cut with this machine, too?

A: Yes- the unit has easy cutting capability, besides welding and cleaning.