Introduction Of Basic Operation Flow Of Asphalt Mixing Station

First of all, before the equipment starts to work, the operator should carry out a full inspection of its working environment, including its parts and whether the device is normal, if found any abnormal situation, must be dealt with in a timely manner, to the asphalt mixing station equipment repair before the operation can be carried out.

First of all, before the equipment starts to work, the operator should carry out a full inspection of its working environment, including its parts and whether the device is normal, if found any abnormal situation, must be dealt with in a timely manner, to the asphalt mixing station equipment repair before the operation can be carried out.

Emulsified Asphalt Plant Mixing cold regeneration technology is to the original asphalt road surface milling recovery materials, after crushing, screening, according to the design requirements of the matching ratio into a certain proportion of emulsified bitumen, cement and admixture, often warm mixing, paving, milling, health after use as a base or surface is a production process.

n

If this is the second reason, then we also need to measure the actual voltage situation to judge.

The specific method is: rotary commutator valve, if the specified voltage conditions can still be normal steering, then it is the electric furnace problem, need to deal with.

On the contrary, it shows that the circuit is normal, and the electromagnetic ring of the asphalt mixing station should be tested accordingly.

n

Judging from years of production experience, in the work of asphalt mixing station, there will be some failure problems, usually due to electromagnetic coil problems and circuit problems caused.

Therefore, in the actual production of the work, we must distinguish between these two different faults, and take the corresponding solutions to deal with each other.

.

The main feature of portable asphalt mixing equipment is that it is installed on a flat trailer, which can be transported to different construction sites and then put into use after a simple and quick installation.

n

It is important to note that no matter what kind of fault, we should ask professionals to carry out testing and processing, so that the operation can ensure the safety of operations, but also conducive to maintaining the safety and smoothness of asphalt mixing station.

Then, in the production process, not only to ensure that the operation of the equipment is in good condition, the staff, but also to configure the relevant testing equipment, the moisture content of the material and fuel, etc., and record the detection of relevant data, for the operator to adjust the operation in a timely manner, so that the asphalt mixing plant equipment in good condition.

.

3, the main equipment

The main equipment used in the cold regeneration of the factory are: Milling machine, recycled mixture mixing station, transporter, paver, steel wheel roller, wheel rubber roller machine and so on.

.

Portable asphalt mixing equipment has the characteristics of large mixing capacity, strong mixing ability, high production efficiency, convenient transportation and so on, and is favored by construction enterprises all over the world.

.

1. Technical advantages

(1) Milling of the old asphalt mixture (with the base milling together, including the base material) can be fully recycled, reduce the cost of raw materials, reduce environmental pollution.

We know that the first task of production is to ensure safety.

In the process of operating the device, the staff must always pay attention to using the correct mode of operation to work.

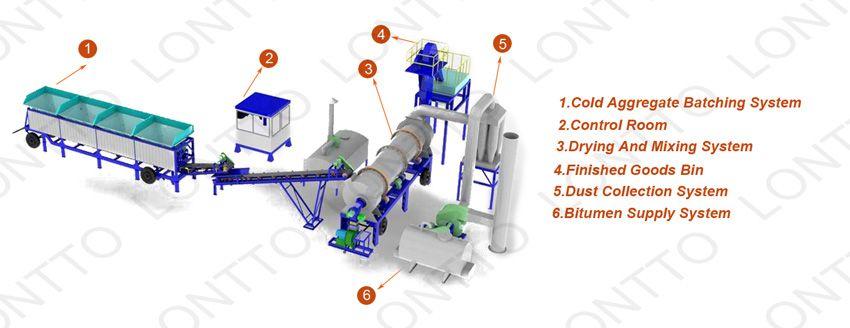

About asphalt Mixing plant, is used for the production of asphalt mixture, modified asphalt mixture and color Asphalt Drum Mix Plant mixture, etc., to meet the needs of highways, grade highways, municipal roads and airports.

When the production work is finished, it should still be carried out according to the correct order of operation, first end the feeding work, and then in the shutdown burner, with hot fine material wash mixer, drain the drying drum and mixer inside the heat material, when the drying drum temperature between the 45~500度, engraved off the drying drum, blower, dust removal system, Finally, do not forget to cut off the asphalt mixing station operating room total power supply

>Secondly, all the operation procedures must be carried out according to the correct requirements, not to change the order of operation at will

>After the machine is started, the staff should pay attention to the operation status of each component, whether it can cooperate well, after the start of production, should be enough to observe the asphalt mixing station mixer work is abnormal, whether the components are coordinated with each other

>

>If we check the asphalt mixing station and find that it is due to the problem caused by the electromagnetic coil, then we should use the meter first for troubleshooting

>The specific method content is: the measuring instrument and the electromagnetic coil voltage connection, measure the actual value of the voltage, if consistent with the specified value, then prove that the electromagnetic coil is normal

>If it does not match the specified value, we also need to continue the troubleshooting, such as the need to check the power supply and other forming switch circuit is abnormal, and processing.