Traceability is the ability of a system to track and trace every single part, product or batch through the complete manufacturing process. It starts from the movement when a raw material is entered into the manufacturing unit/factory to the movement a final and finished product is ready for shipping.

This process of Traceability helps/allows the manufacturing units to digitally connect their each and every single part, product or batch to the Sub-assembly, the Main assembly and finally to the Final assembly. This is required and very much in need of the industries to maintain their products quality to save their brand image along with the sustenance in the markets competitive environment and to gather Customers Loyalty.

Objectives of traceability:

- Enhancing Supply Chain Administration

- Encouraging tracing back for sustenance security & quality.

- Separating and marketing products with indistinct quality traits

In Manufacturing Traceability systems are found in both part and batch production. Here mentioned are elements which are connected to the design of a batch-tracing-system:

- Physical lot-integrity – This refers to the size of the batch of raw material and how good the integrity of the considered batch is maintained. This will determine the perfection of the traceability solution considered.

- Data collection – For Data collection there is requirement of Two types of data. One is Process data which will provide the process information and second is Lot-tracing data that will provide the information related to the movement of product batches.

- Product identification - This refers to the connection of identified product data and process data.

- Reporting – It is the use of generated data and visualization of same.

What are components used for Traceability Solutions?

Here are few components used for Traceability solutions:

- MES

- ERP

- Data Capture and Mobility Software

- Additional Hardware Systems

- Professional Services

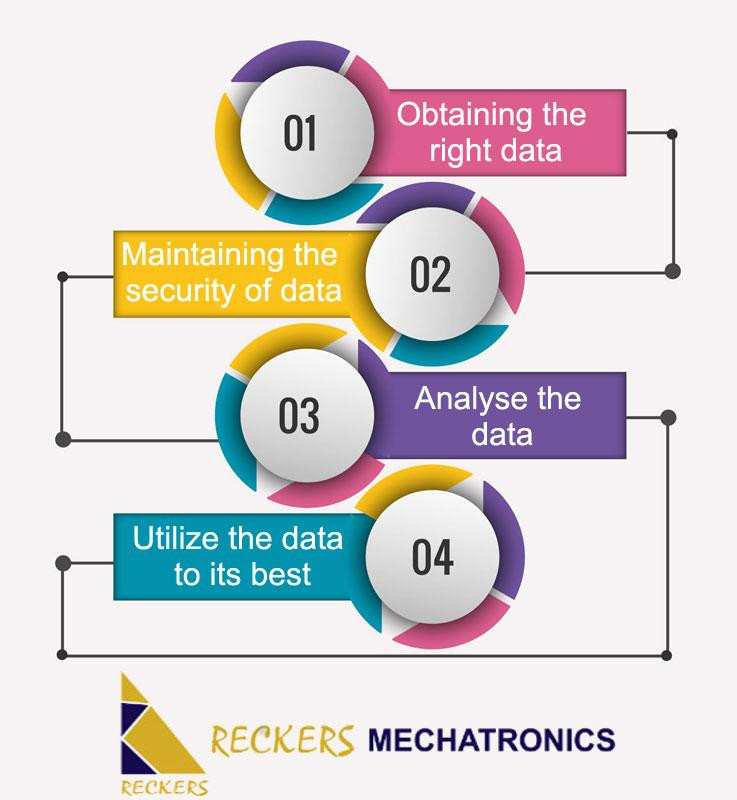

What are the steps involved in Implementation of Traceability?

Here mentioned are few steps for Implementation of Traceability Solutions:

Step 1: Identifying which information should be marked on the part, product or batch.

Step 2: Selection of required marking equipment

Step 3: Verifying Accuracy

Step 4: Integrating marking equipment with enterprise software for enabling industrial data and analytics

What are the Benefits of Traceability Solutions?

Here mentioned are few of the benefits of Traceability Solutions:

- Increases manufacturing operational productivity.

- Improves Data Accuracy

- Real Time Visibility

- Decreases Manual Dependencies

- Increase Customer Satisfaction, Loyalty and Safety.

CONTACT : Gunjan Santia,

Inside Marketing Manager

COMPANY : Reckers Mechatronics Pvt. Ltd.

PHONE : 9212728006

EMAIL : gunjan@reckersmech.com

For more information, you can contact us at: https://reckersmech.com/