Guest post by Diarmuid Foley.

A small modular nuclear reactor to replace coal plants could be on the market within 5 years.

In 2014, the Generation IV international forum[1] confirmed the Very High Temperature Reactor (VHTR) as one of 6 promising reactor technologies that should be pursued in order to develop advanced reactors suitable for deployment in the 2030’s.

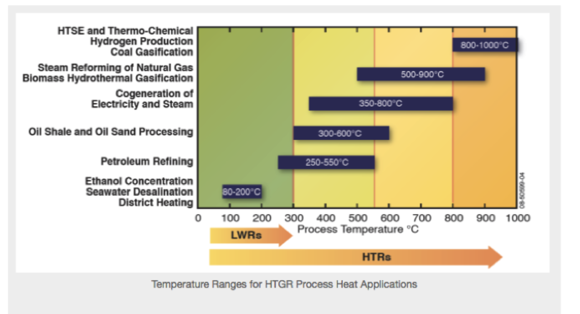

The VHTR design was initially targeted at reactor outlet temperatures of up to 950 -1000 °C for process heat applications. Such temperatures would enable the thermo-chemical production of hydrogen and other products without producing carbon emissions. Electricity generation would use a direct-cycle helium gas turbine.

In recent years, commercial development has focussed around reactors with output temperatures in the range 700-850 °C using a steam cycle, as this range is seen as having the greatest near-term potential. These designs are now referred to as High Temperature (Gas) Reactors – HTR or HTGR.

Figure 1: Key industrial process heat applications and operational temperature range for light water reactors ( LWR ) & high temperature reactors ( HTR )

History

The HTR has more than 50 years of somewhat chequered history behind it. The first plants were small experimental ones – a 20 MWe unit in the UK & a 15 MWe unit in Germany that came online in 1966. This latter was followed by a commercial unit that was designed to burn thorium. However, the German project ran into political and technical headwinds and was abandoned in 1989.

In the U.S. 2 commercial (i.e. power producing) plants were built – a 40 MWe experimental unit at Peach Bottom which ran from 1966-1975 and provided the learning foundation for the much larger 330 MWe plant at Fort St Vrain, which ran from 1976 to 1988. This latter reactor established the technical feasibility of HTR’s although further development was required to justify the economic case.

Design & technical details

Most HTR’s use helium as coolant, but super-critical CO2 and nitrogen can also be employed.

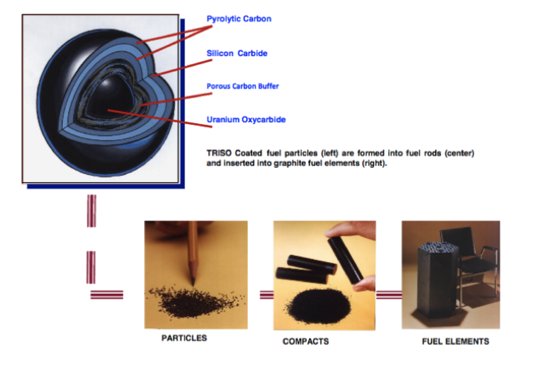

Figure 2: The HTR uses many billions of individual fuel elements

The distinguishing feature of all high temperature reactors is the use of TRISO (Tri-Structural Isotropic) fuel, placed either in a pebble-bed or a prismatic block type configuration.

The solid fuel is encapsulated inside extremely small silicon carbide/carbon casings of less than 1mm diameter. This provides for a highly secure containment of the fuel and fission products during operation and indeed for spent fuel as no water or active cooling system is required for spent fuel storage.

TRISO fuel particles are designed not to crack due to the stresses from processes (such as differential thermal expansion or fission gas pressure) at temperatures up to and beyond 1600 °C, and therefore can contain the fuel in the worst of accident scenarios in a properly designed reactor.

This fuel from is currently being used in two experimental reactors; the HTR-10 in China, and the HTTR in Japan.

High efficiency

HTR reactors have thermal efficiencies of ~42% on steam cycle and potentially 50% or greater on a gas turbine cycle. Demonstration and proving of a coupled gas turbine remains a high development priority.

Safety case

An important safety feature of the pebble-bed reactor is that it will not crack, melt, explode or spew hazardous waste, even if all of the supporting machinery fails. It simply goes up to a designed “idle” temperature, and stays there. While it radiates a manageable amount of heat, the vessel and fuel spheres remain intact. Accordingly the HTR design is recognized by the IAEA as “inherently safe” as it cannot melt down.

The design also benefits from a very strong negative coefficient of reactivity. Furthermore as helium has a very low neutron cross-section, it is not easily activated and presents no risk of radionuclide release in the event of a coolant escape.

Plant siting

One of main attractions of the HTR design is that there is no requirement for large volumes of cooling water, which in conjunction with the greatly enhanced safety case, means plants can potentially be sited much closer to centers of use.

Spent fuel & waste

Spent fuel can be stored without an active cooling system – air circulation is sufficient. Furthermore, the fuel form is ideal for long term storage.

Chinese program

There are government sponsored HTR programs in China, Japan and South Korea but it is the Chinese program that is the most interesting.

In the 1990’s, the Chinese licensed the considerable work that had been undertaken in Germany in earlier years and set about resolving the technical issues that had beset the program there. It began construction of its first experimental reactor of 10 MWe in 1995 at Tsinghua’s university energy centre – the Institute of Nuclear and Energy Technology or INET – and this unit went critical in 2000, subsequently supplying power to the campus.

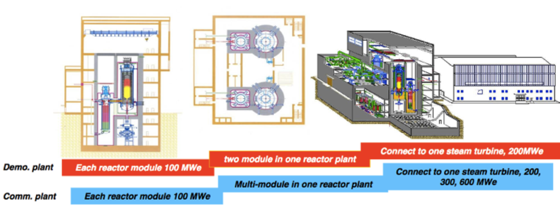

Figure 3: China’s HTR program is built around standard 100 MWe modules which can be coupled to a single steam turbine.

This proved an operational success and as a result a decision was taken to build a full-scale demonstration unit[2] [3].

Construction of this unit began in 2012 at Shidao Bay, some 900 km south east of Beijing. This will consist of two modules of 100 MWe coupled to a steam turbine. They are designated HTR-PM which stands for High Temperature Reactor, Pebble-bed Modularized. Construction is at an advanced stage and the units are expected online in 2018.

Potential substitute for coal plants

One of China’s stated goals for developing the HTR is that they have the potential to substitute for the combustion unit in its fleet of modern supercritical coal plants, as they produce similar steam turbine inlet conditions. As many of China’s coal plants are located close to cities, this is seen as a potential route for quickly improving air quality.

Economics & mass deployment

The concept is firmly based around volume production of standardized modules. The target capital price for serial production is $2 – $2,500/kW of capacity and the Chinese are very clear on costs – they want utilities to choose these units over coal technology.

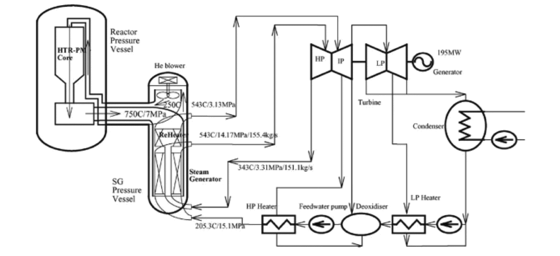

Figure 4: Schematic of China’s HTR-PM. Steam turbine inlet conditions are similar to modern coal plants, circa 550C

The HTR-PM modules can withstand complete loss of pressurization and helium flow without a forced shutdown and still not release enough radioactive materials to exceed the very conservative dose limits in place today.

According to Professor Zuoyi Zhang of INET, the design is such that up to 6 modules can be combined to give some 600 MWe of power, which is similar to the size of more modern supercritical coal units.

“This technology is going to be on the world market within the next five years,” Zhang predicted in 2016. “We are developing these reactors to belong to the world.”

North America

The U.S. adopted its own advanced reactor initiative in 2005 (termed the Next Generation Nuclear Plant or NGNP [4]). The program is presently focussed on qualifying the TRISO fuel to the satisfaction of the regulator, along with other supporting tests at national laboratories.

Current commercial design and engineering developments in North America are being led by X-Energy & General Atomics in the U.S. and Starcore Nuclear in Canada.

Maryland based X-Energy is developing a 50 MWe module which can be arranged to form a plant up to 200 MWe. In 2016 it was awarded a 5 year $40Million grant by the Department of Energy to further develop its technology in conjunction with leading national nuclear laboratories & private companies.

Meanwhile, General Atomics has developed the conceptual design for a 265 MWe fast spectrum HTR. It is unclear how advanced this program is.

But licensing reform in the U.S. remains the key issue.

Although the U.S. regulator – the NRC – has recently issued its vision statement for the licensing of non-light water reactors[5], the timeframe – with full implementation not until 2025 – remains a major impediment and frustration for U.S. developers, who have indicated that more fundamental reform needs to happen, much sooner.

Canada

Canada successfully developed it’s own water-cooled reactor, the heavy water based CANDU design. It is seen by many reactor developers as one of the more attractive Western markets in which to seek to first license an advanced design.

StarCore began the pre-licensing engagement process (known as the Vendor Design Review) with the Canadian regulator, CNSC, in November 2015. This is expected to take up to 18 months after which the company will be in a position to decide whether to proceed with a full license application.

Starcore’s technology is also based on using TRISO encapsulated fuel in a pebble bed configuration. They have designed a unit size of 20 MWe expandable to 100 MWe.

The company’s business plan is to sell electricity rather than sell reactors. Their target price at up to $140/MWh is high for large grids but their market is remote communities which would typically be paying considerably more than this for diesel-generated electricity and heat.

Industrial process heat (IPH)

A strong logic underpinning HTR development is its potential use for generating industrial process heat. A recent EU-funded research program[6] put the global market for industrial heat at 946 – 1,376 Mtoe, although the immediately accessible market for nuclear heat is estimated to be smaller at 260 – 430 Mtoe, equivalent to

3 – 5,000 TWh/year. Such a market would require at least a doubling of current reactor capacity.

Furthermore, this report estimated that 2/3rd of IPH is required at temperatures below 700°C which fits with the HTR’s operating range.

This is a substantial market considering that global energy use – from all sources – was 13,684 Mtoe in 2014[7].

Economics

A key reason for developing the HTR is its inherently safe design. The majority of the equipment in current large water-cooled reactors is redundant safety systems which adds enormously to cost as well as regulatory complexity. With a simplified safety case and volume production, costs are projected to halve, making this design competitive with modern coal-fired plants. Levelized costs of electricity of less than 6.5¢/kWh are projected.

Future developments are expected to take advantage of the much higher efficiencies that a direct cycle, based on a gas turbine, can offer. Research on this technology is on-going at many of the locations mentioned.

The next couple of years promise to be interesting for advanced nuclear. All eyes will be on China’s demonstration unit and whether it can prove that this design is ready to enter commercial operation in the next decade.

About the author: Diarmuid Foley is an engineer and advocate for nuclear energy. He holds a masters in nuclear engineering from Imperial College London and is currently researching advanced nuclear for electricity and industrial heat applications at University College Cork. Twitter: @DiarmuidFoley1

[2] https://www.iaea.org/NuclearPower/Downloadable/Meetings/2014/2014-04-08-04-11-TM-NPTDS/2_Li01.pdf

[3] https://www.iaea.org/NuclearPower/Downloadable/Meetings/2015/2015-08-25-08-28-NPTDS/DAY1/5._DONG_Y-201508V2.pdf

[5] https://www.regulations.gov/document?D=NRC-2016-0146-0002

[6] http://cordis.europa.eu/result/rcn/56098_en.html

[7] IEA – World Energy Outlook 2016

The post History and promise of high temperature gas cooled reactors appeared first on Atomic Insights.

Source: EnergyCollective

Plus sur le sujet: ITER n'est pas la seule voie de recherche pour une production d'énergie infinie