1. Centrifugal Pumps

2. Self Priming Centrifugal Pumps

3. Jet Pumps

four. Deep Nicely Pumps

five. Multi-Stage Pumps

six. Submersible Pumps

Pumps for properties and industries have progressed over time. Just before the 1950's a substantial amount of persons lived in towns where by that they had a central water method. Central units make use of significant centrifugal pumps. Outside the town there were no central h2o programs. In case you moved exterior the town you essential a perfectly (or cisterns) along with a pump to provide your drinking water desires. Because the Centrifugal pumps weren't created economically for use in houses at that time, these non-town dwellers made use of piston (reciprocating) pumps to deliver their drinking water desires from wells and cisterns. Eventually from the early 1950's centrifugal pumps, that were built specifically and economical for home wells, began to arrive on the market.

These initially straight centrifugal (SC) shut coupled pumps (pumps joined together with motor and pump) had a motor, a seal plate (or adapter), a mechanical shaft seal, an impeller and also a volute (casing) that match around the impeller. Most volutes had have on rings that were replaceable and healthy snug around the skin eye from the impeller. These pumps normally turned at 3600 RPM's. Since they ran (or turned), the impeller slung drinking water from inside of out which produced a vacuum inside the eye (or consumption) on the impeller. These pumps had been made with little if any lift. They have been created to have a flooded suction (reservoirs, cisterns or artesian wells). They took the intake h2o and were ready to boost it to thirty to 50 PSI or a little increased. They were ready to pump a great deal of quantity.

Eventually in spots with little if any rainfall, residence house owners needed to drill wells that primarily experienced drinking water amounts below floor. With centrifugal pumps having little or no lifting abilities there was a necessity for pumps that could lift or drive h2o from underneath ground level. Engineers first came up using a "self-priming" centrifugal (SPC) pump. These pumps employed the identical factors as a straight centrifugal pump aside from two things that ended up adjusted. An inner diffuser was additional to your pump that bolted around the impeller, along with a larger sized volute (casing). While using the diffuser and larger casing these pumps could vent the air to key and raise water as many as 25 toes successfully. As a result of their design and style demanding them to now elevate drinking water, they created h2o at the amount of about fifteen% lower than a straight centrifugal pump. They also created a little less tension. Usually, they operated while in the twenty -40 PSI assortment. Their structure manufactured them deliver maximum volumes of drinking water at the very best issue of its highest strain. We simply call these pumps a medium head/medium tension form pump.

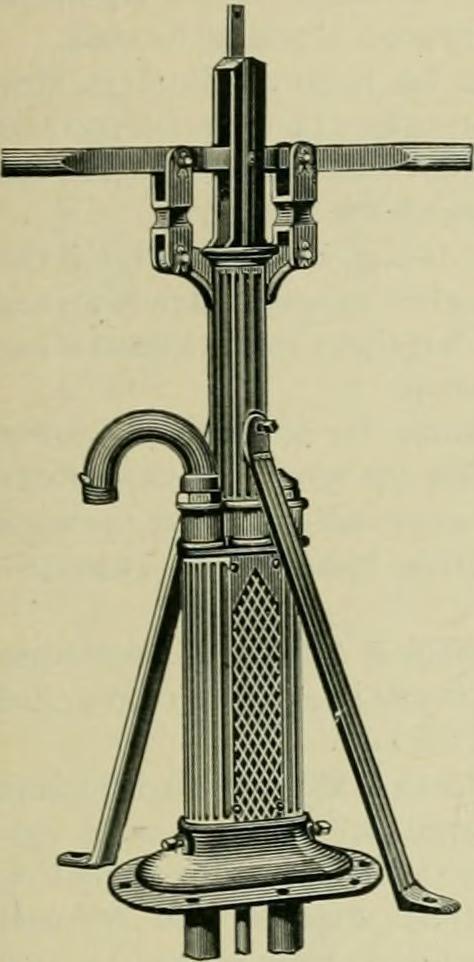

As houses and corporations grew outside the town, there was a necessity for pumps to deliver better pressures rather than greater quantities of drinking water. A mean household would need one hundred to a hundred and fifty gallons daily. At peak intervals (for example early in the morning), on the other hand, h2o desires may very well be 15 gallon for each minute (GPM). Engineers then came up that has a centrifugal jet pump. Moreover possessing all of the factors of the self-priming centrifugal pump, engineers included a bolt on shallow properly jet.

These pumps were smaller sized in dimensions than self priming centrifugal pumps (SPC), on the other hand, they may deliver the amount of drinking water the customer needed (usually 10 to twenty gpm) at pressures up to sixty PSI. When comparing horsepower (HP) to horsepower (HP) of a jet pump into a self-priming centrifugal (SPC), the SPC could deliver far more h2o, but at reduced pressures - some thing the homeowner didn't actually need. These shallow properly jet (SWJ) pumps operated just like a SPC pump other than after the water was lifted and pulled during the pump from the impeller, A part of the water was diverted from the jet boosting the stress. These pumps could elevate h2o approximately twenty five toes from ground degree, nevertheless, at depths reduce than 15 ft these pumps have been straining to carry water.

he engineers solved the problem of inefficiency at drinking water stages under fifteen ft by installing the shallow effectively jet inside the nicely on twin pipes. These twin pipes have been attached to two holes in the pump casing, 1 suction hole and one driver gap. A Particular four" effectively seal at the top with the well would guard contaminates from getting into the well.

The jet experienced a one way valve on the bottom (foot valve). They also included an computerized Regulate valve (sometimes referred to as a back again tension or Handle valve) on the discharge from the pump. This could develop a deep effectively jet pump (DWJ). The DWJ pumps lifted the water up throughout the pump impeller. Part of the water discharged through the BPV to the home or property, and Element of the water was diverted back again down the perfectly in the driver line. H2o would recirculate throughout the deep properly jet which would aid lift a lot more h2o and produce better pressures.

Due to this twin pipe process all wells needed to be four" within diameter or bigger. Ultimately a modified deep nicely jet was made for 2" and three" within diameter wells. In This method, only one drop pipe was desired While using the deep perfectly jet and foot valve on the tip. This new jet used cup leathers that sealed the interior pipe towards the outer perfectly casing. There was a Unique properly seal at the best from the well built to hold the fall pipe and seal within the well casing. From there, two pipes would hook up into your pump. These modified jets could generate over sufficient drinking water wanted for a house.

Whether or not the pump method was a shallow properly or deep effectively techniques, scenarios occurred wherever The shoppers required reasonably minimal volumes of water, but at pressures around 60 PSI. Engineers arrived up with the answer - multi-stage (multi-impeller) pumps. Shallow properly jet pumps that desired to produce pressures in excess of 60 PSI have been now created with two or more impellers. They operated by the initial impeller lifting the drinking water and then throwing it into the subsequent impeller.

The primary impeller lifting the entire GPM's wanted, nonetheless, by throwing the h2o into the next impeller in elevated the tension from 10 to 15 PSI. If it experienced more than one impeller then the 3rd impeller would Raise the stress a further ten to fifteen PSI. It's because the additional impellers didn't have to carry any quantity of drinking water. Simply because water volume is body weight and the pump did not pump extra goulds shallow well pump h2o than a one particular stage (just one impeller pump), then This might be done with out rising the pump horsepower.

Noting how thriving the multi-stage pumps worked, engineers came up with the thought of planning a tube like pump and motor that will match inside a 4" very well. This pump would've a number of impellers and become submerged (submersible properly pump) inside the perfectly on fall pipe underneath the h2o. An electric cable would be attached into the pump and run via a Distinctive nicely seal at the top of your nicely. The motor was on The underside, the water ingestion was in the center as well as pump was on the highest. H2o would now go with the motor (cooling it) and become pulled into your pump. Now effectiveness seriously arrived into put.

Now that the pump only had to push the h2o up in lieu of re-flow into the water inside the properly via a deep perfectly pump method, these pumps could deliver a lot far more water at higher pressures than exactly the same horsepower as their above ground counterpart jet pumps. In many of the place today, drinking water degrees in wells can be very deep (sometimes 300 to 500 ft beneath ground level). Nowadays eighty five% of all wells are 4" in diameter or greater and utilize a submersible pump. Lately, a 3" submersible pump arrived in the marketplace to ensure that existing 3" wells being adjusted over from deep properly jet process to submersible nicely pumps.

Submersible very well pumps are available in two types. Very first there is a 3 wire pump which has a floor wire. These pumps have their commencing components mounted above floor inside a Management box (ex: setting up relays and capacitors). These factors are the ones that happen to be the most common to are unsuccessful. They now can be replaced very easily without the need to utilize a hoist truck to elevate the pump out of the properly. The next kind of submersible effectively pump is a two wire kind with ground wire. Every one of the starting parts are within the pump motor, As a result the pump should be pulled through the nicely to be worked on.